Woven-structure stretchable fabric circuit board and wearable equipment

A technology for circuit boards and fabrics, which is applied in the field of stretchable fabric circuit boards with woven structures and wearable devices, and can solve problems such as poor air permeability, large resistance, and large relative changes in contact resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

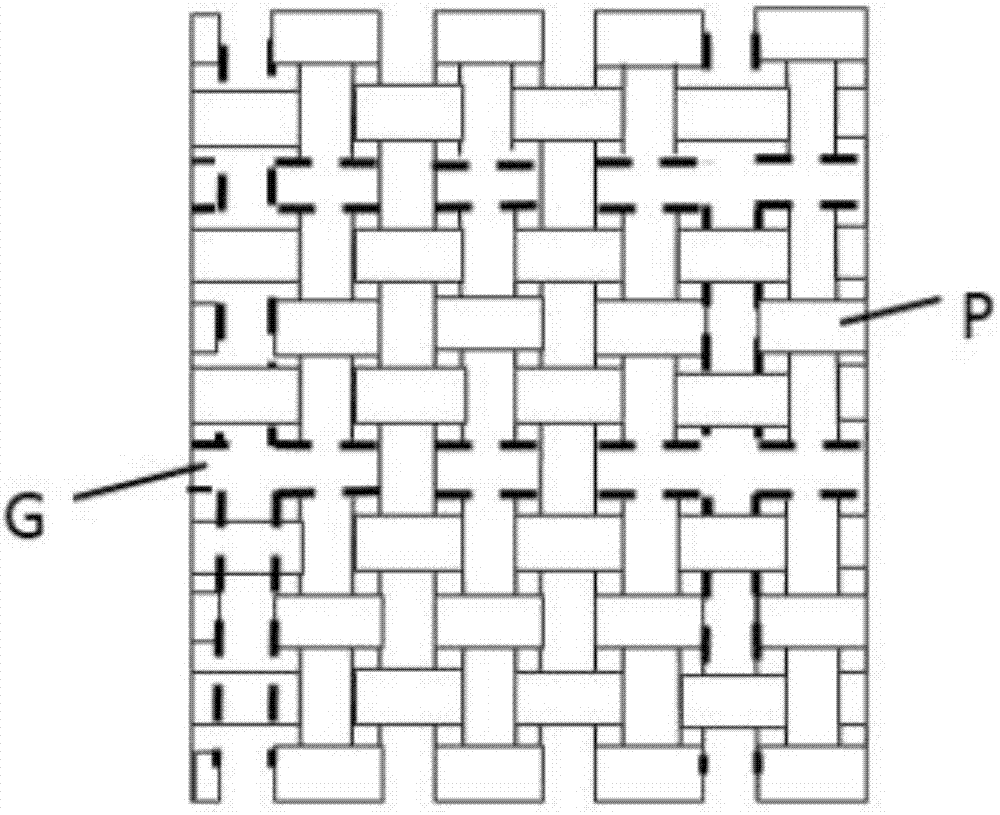

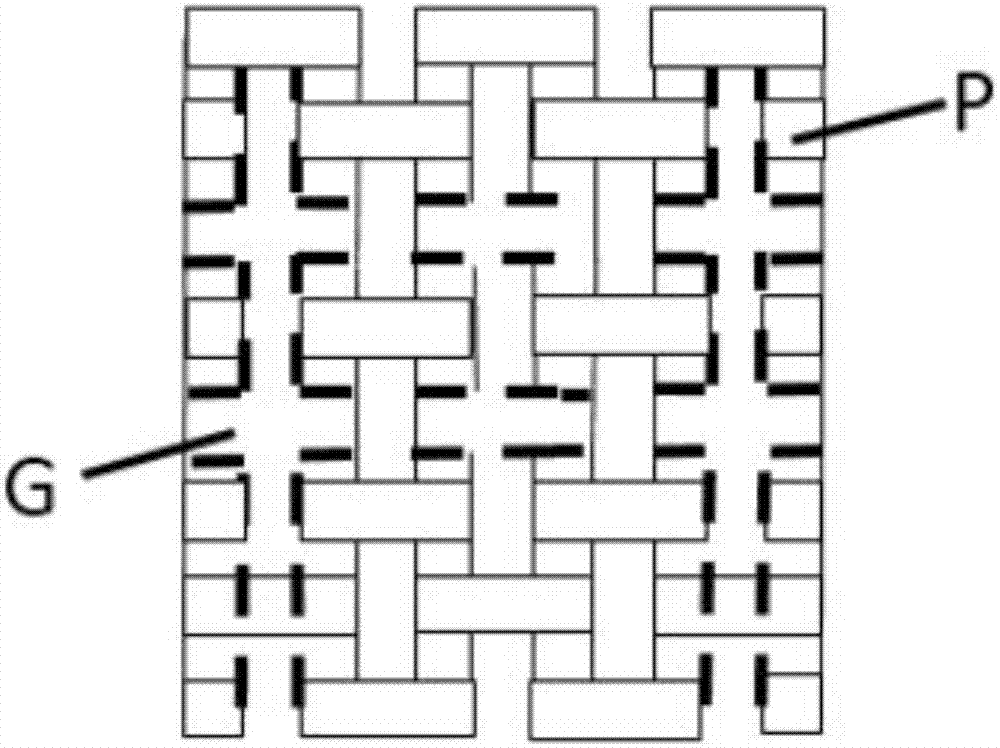

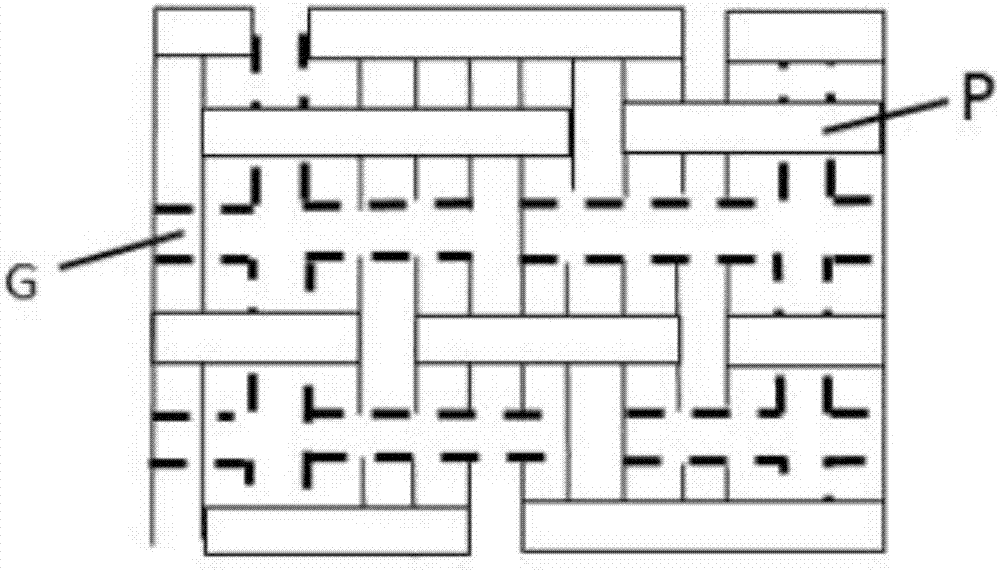

[0029] Twill weave structure design:

[0030] One upper three lower right twill weave is used as the basic weave of the base part of the fabric circuit board, silver thread and 140D / 70D / 70D black wrapping yarn are used for the warp yarn, and cotton yarn is used for the weft yarn (see figure 2 ). First, by confirming the sensing position of the upper body of the human body, the position of the conductive yarn in the fabric and the setting of the spacing distance are designed, and the warp and weft yarn density and reed number are calculated according to the shrinkage rate of general tights, and the conductive yarn is woven into the form on the rapier loom. Stretched fabric circuit board, wherein one conductive yarn is woven into the sub-circuit part each time, and two conductive yarns are woven into the main circuit part each time to show the distinction.

[0031] Electronic component connections for fabric circuit boards:

[0032] After the fabric circuit board is completed...

Embodiment 2

[0036] Using platinum wire as raw material, using flat knitting technology, the conductive fiber exists in the form of knitted coils, thereby preparing a stretchable fabric strain sensor. Using copper wire as raw material, using advanced weaving technology, a flexible connection circuit is prepared. The elastic fabric circuit is used to realize the close connection between various sensors in wearable devices, so as to realize the transmission of signals and the collection of information.

Embodiment 3

[0038] Using silver / nylon fibers as raw materials, conductive fibers were integrated into elastic woven fabrics to prepare elastic conductive tights. Integrating printed coating strain sensors and flexible capacitors with three-dimensional structure onto the fabric realizes a complete connection between circuits and components, thus sending signals to the data acquisition place.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com