Processing method of cortex eucommiae tea

A processing method and technology of Eucommia tea, applied in the direction of tea substitutes, etc., can solve the problems of low content of beneficial components, bitter taste of Eucommia tea, and unacceptable, and achieve the effect of inhibiting enzymatic reaction and increasing cell permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

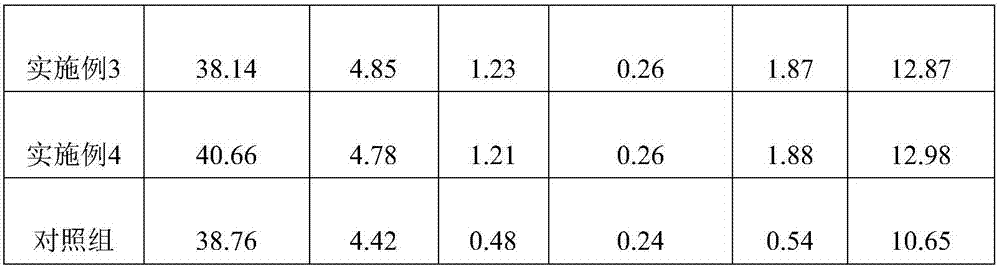

Examples

Embodiment 1

[0031] A method for processing Eucommia ulmoides tea, comprising the following steps:

[0032] 1) material selection: take the fresh leaves of Eucommia ulmoides and remove the petioles as tea raw materials;

[0033] 2) Withering: including sunlight withering, withering groove withering, and solar withering at 16:30-18:00;

[0034] 3) Shake the green: the withered tea leaves and the solution 1 are mixed in a mass ratio of 30:1 to shake the green;

[0035] 4) Fixing: Shake green leaves for fixing, including microwave fixing and steam fixing;

[0036] 5) Kneading: the green leaves are kneaded, the temperature of the kneading chamber is 22°C, the relative humidity is 87%, and the pressure is 700Pa;

[0037] 6) Drying: Drying includes initial drying, frying, the initial drying temperature is 110°C, the moisture content of the tea leaves is 50%, and after cooling for 3 hours, the frying is performed at a temperature of 67°C, and the moisture content of the tea leaves is 6.0%.

[...

Embodiment 2

[0053] A method for processing Eucommia ulmoides tea, comprising the following steps:

[0054] 1) material selection: take the fresh leaves of Eucommia ulmoides and remove the petioles as tea raw materials;

[0055] 2) Withering: including sunlight withering, withering groove withering, and solar withering at 16:30-18:00;

[0056] 3) Shake the green: the withered tea leaves and the solution 1 are mixed in a mass ratio of 30:1 to shake the green;

[0057] 4) Fixing: Shake green leaves for fixing, including microwave fixing and steam fixing;

[0058] 5) Kneading: the green leaves are kneaded, the temperature of the kneading chamber is 22°C, the relative humidity is 87%, and the pressure is 700Pa;

[0059] 6) Drying: Drying includes initial drying, frying, the initial drying temperature is 110°C, the moisture content of the tea leaves is 50%, and after cooling for 3 hours, the frying is performed at a temperature of 67°C, and the moisture content of the tea leaves is 6.0%.

[00...

Embodiment 3

[0074] A method for processing Eucommia ulmoides tea, comprising the following steps:

[0075] 1) material selection: take the fresh leaves of Eucommia ulmoides and remove the petioles as tea raw materials;

[0076] 2) Withering: including sunlight withering, withering groove withering, and solar withering at 16:30-18:00;

[0077] 3) Shake the green: the withered tea leaves and the solution 1 are mixed in a mass ratio of 30:1 to shake the green;

[0078] 4) Fixing: Shake green leaves for steam fixing;

[0079] 5) Kneading: the green leaves are kneaded, the temperature of the kneading chamber is 22°C, the relative humidity is 87%, and the pressure is 700Pa;

[0080] 6) Drying: Drying includes initial drying, frying, the initial drying temperature is 110°C, the moisture content of the tea leaves is 50%, and after cooling for 3 hours, the frying is performed at a temperature of 67°C, and the moisture content of the tea leaves is 6.0%.

[0081] 7) Package.

[0082] In the with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com