A kind of black low-temperature sintered microwave dielectric ceramic material and its preparation method and application

A microwave dielectric ceramic and low-temperature sintering technology, which is applied in the field of microwave dielectric ceramics, can solve the problems of affecting signal transmission speed, complex process, high difficulty, etc., and achieve the advantages of microwave dielectric characteristics, simple firing process, and manufacturing cost advantages.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

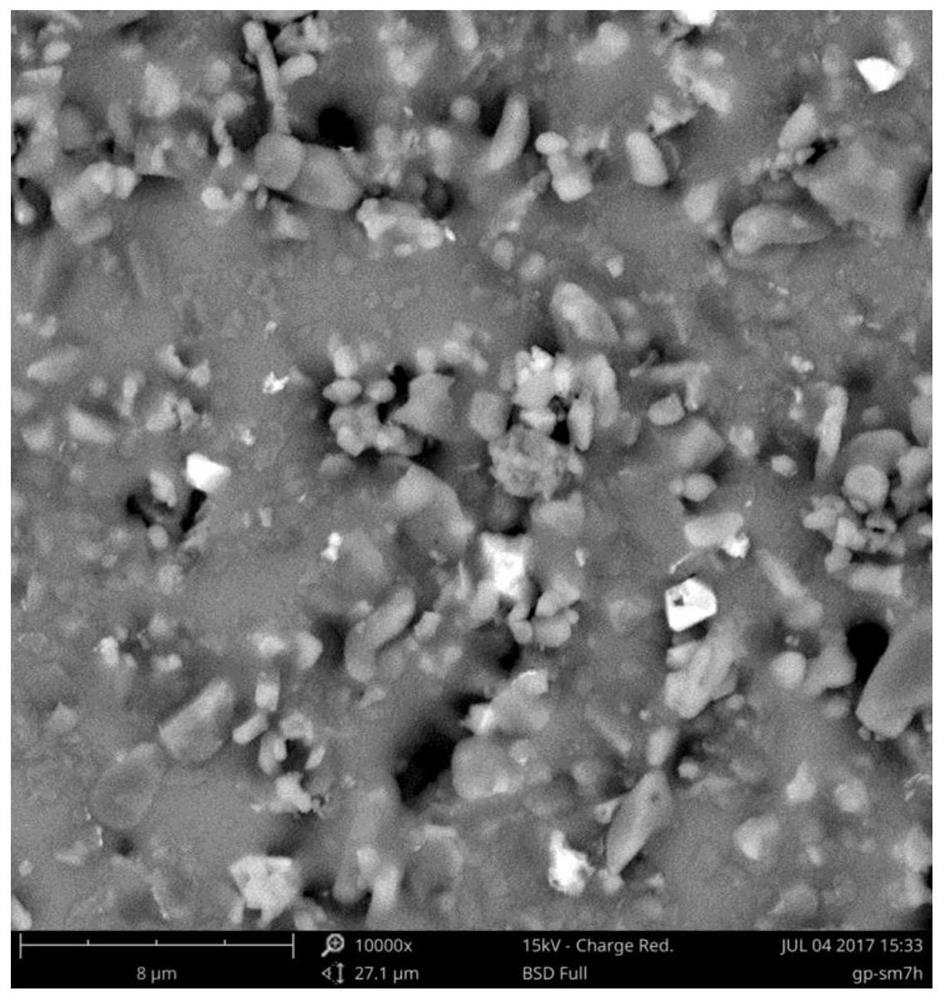

[0034] The preparation method of the black low-temperature sintered microwave dielectric ceramic material provided by the invention comprises the following steps.

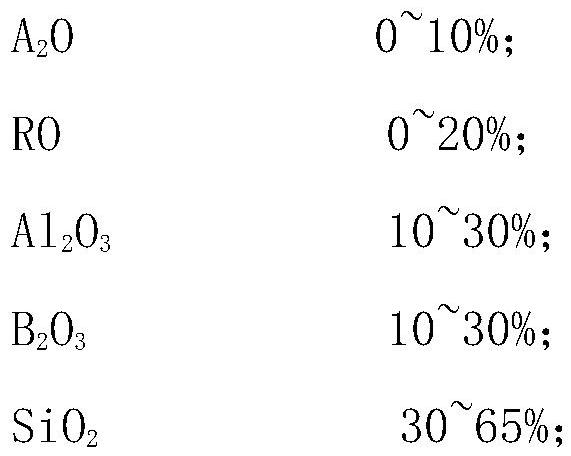

[0035] Preparation of aluminoborosilicate glass: Proportion by mass: 0~10%A 2 O(Li 2 O, Na 2 O or K 2 One or more of O), 0-20% RO (one or more of MgO, CaO, BaO), 10-30% Al 2 o 3, 10~30%B 2 o 3 , 30-65% SiO 2 . Weigh Li 2 CO 3 、Na 2 CO 3 or NaHCO 3 、K 2 CO 3 or KHCO 3 , MgO or basic magnesium carbonate, CaCO 3 , SrCO 3 、BaCO 3 , B 2 o 3 or H 3 BO 3 、Al 2 o 3 and SiO 2 , choose ZrO 2 Grinding balls, mixed by dry method for 1-6 hours, then put the mixed powder into a platinum crucible, heated to the melting temperature of 1400-1550°C, kept warm and homogenized for 0.5-1 hour, then poured into water to quench. The obtained glass fragments are ball milled and dried to obtain a glass powder with a particle size D50 of 1.5-3.0 μm.

[0036] Black colorant CuCr 2 o 4 Preparation: Weigh Cr at a ...

Embodiment 1-2

[0044] The composition of the aluminoborosilicate glass in this embodiment is shown in Table 1, and the composition of the black low-temperature sintered microwave dielectric ceramic material is shown in Table 2.

[0045] The preparation process of the black low-temperature co-fired microwave dielectric ceramic material of this embodiment is as follows:

[0046] (1) Preparation of aluminoborosilicate glass: take by weighing Na according to the mass ratio in Table 1 2 CO 3 or NaHCO 3 、K 2 CO 3 or KHCO 3 , MgO or basic magnesium carbonate, CaCO 3 , B 2 o 3 or H 3 BO 3 、Al 2 o 3 and SiO 2 , choose ZrO 2 Grinding balls, mixed by dry method for 4 hours, then put the mixed powder into a platinum crucible, heated to the melting temperature of 1550 ° C, kept warm for 1 hour, and then poured into water to quench. The obtained glass fragments were ball milled and dried to obtain a glass powder with a particle size D50 of 2.5 μm.

[0047] (2) black colorant CuCr 2 o 4 Pr...

Embodiment 3-6

[0051] The composition of the aluminoborosilicate glass in this embodiment is shown in Table 1, B and C, and the composition of the black low-temperature sintered microwave dielectric ceramic material is shown in Table 2.

[0052] The preparation process of the black low-temperature co-fired microwave dielectric ceramic material of this embodiment is as follows:

[0053] (1) Preparation of aluminoborosilicate glass: take Li according to the mass ratio in Table 1 2 CO 3 、Na 2 CO 3 or NaHCO 3 、K 2 CO 3 or KHCO 3 , MgO or basic magnesium carbonate, SrCO 3 、BaCO 3 , B 2 o 3 or H 3 BO 3 、Al 2 o 3 and SiO 2 , choose ZrO 2 Grinding balls, mixed by dry method for 4 hours, then put the mixed powder into a platinum crucible, heated to the melting temperature of 1500°C, kept warm and homogenized for 1 hour, then poured into water to quench. The obtained glass fragments were ball milled and dried to obtain a glass powder with a particle size D50 of 2.5 μm.

[0054] (2) b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com