Low-loss titanium barium stannate dielectric material

A technology of barium titanate stannate and dielectric materials is applied in the field of preparation of low-loss barium titanate stannate dielectric materials, and can solve the problems of large dielectric loss and temperature coefficient, restricting applications, reducing the dielectric constant of materials and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] 1. BaCO 3 、TiO 2 , SnO 2 According to the stoichiometric formula Ba(Sn 0.15 Ti 0.85 )O 3 For batching, the ratio is: 8.172gBaCO 3 , 2.8122g TiO 2 , 0.9287gSnO 2 , put 10g of mixed powder into a nylon tank, add 200ml of deionized water, add 150g of zirconium balls, and ball mill on a planetary ball mill for 6 hours at a speed of 400 rpm.

[0022] 2. Put the ball-milled powder in a drying oven, dry it at 100°C, and pass it through a 40-mesh sieve;

[0023] 3. Pre-fire the dried and sieved powder in a medium-temperature furnace at 1100°C and keep it warm for 4 hours.

[0024] 4. Mix the pre-fired powder in step 3 with 0.5wt% PVA, put it into a ball mill tank, add zirconia balls and deionized water, ball mill for 12 hours, dry and sieve, and then use a powder tablet machine Pressed into a green body with a pressure of 4MPa;

[0025] 5. Sinter the body at 1350°C and keep it warm for 4 hours to make low-loss Ba(Sn 0.15 Ti 0.85 )O 3 medium material.

Embodiment 2~10

[0027] Examples 2-10 are completely the same as Example 1 except for x value, calcining temperature and sintering temperature.

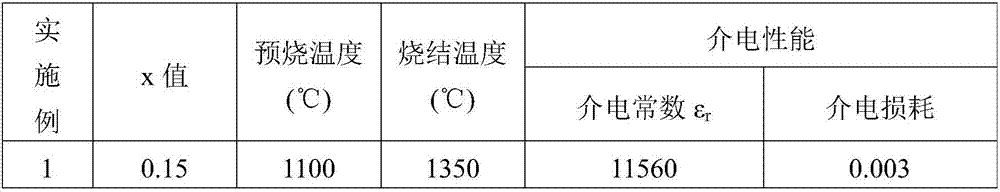

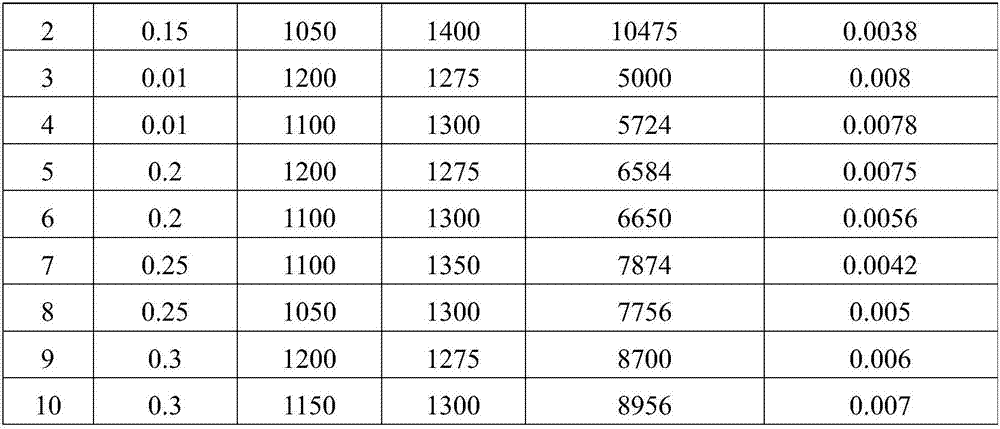

[0028] Specific Examples of the Invention The dielectric properties of the obtained product were tested by HEWLETT PACKARD 4278A (Agilent 4278A) at 1 kHz.

[0029] The relevant process parameters and dielectric properties of specific embodiments are shown in Table 1.

[0030] Table 1

[0031]

[0032]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com