PVC pipe extrusion moulding process capable of effectively increasing impact strength

A technology of impact strength and PVC pipes, applied in the direction of organic insulators, plastic/resin/wax insulators, electrical components, etc., to achieve the effects of convenient construction, excellent chemical stability, and excellent dielectric properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

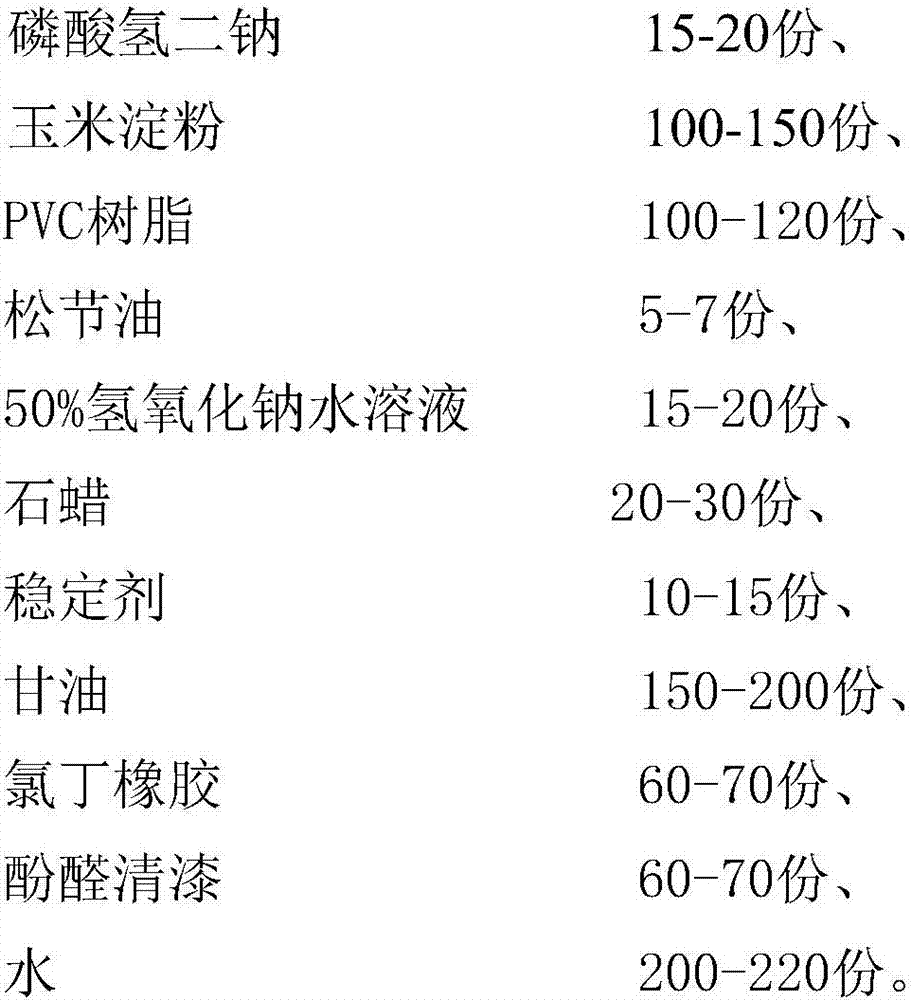

Method used

Image

Examples

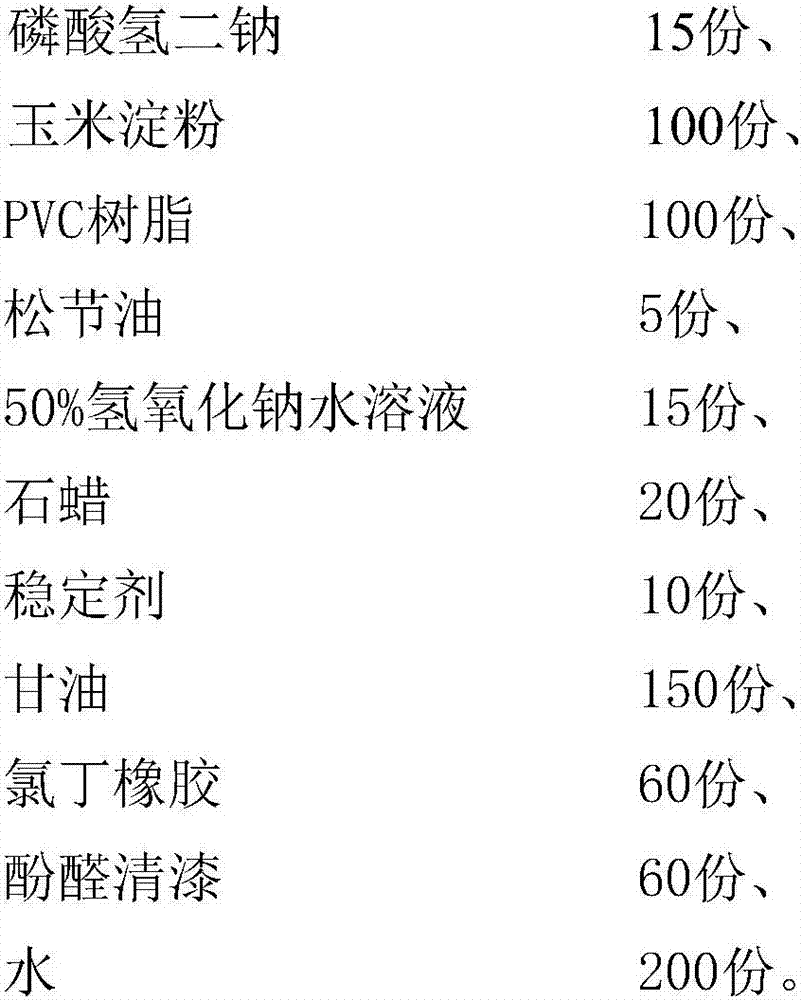

Embodiment 1

[0046]Embodiment 1: A PVC pipe extrusion molding process that effectively improves impact strength. The pipe formulation includes PVC resin, impact modifier, stabilizer, processing modifier, filler, colorant and external lubricant, specifically including Prepared by the following steps: various materials-weighing-kneading-extrusion granulation-extrusion molding-cooling molding-cutting-inspection-finished product;

[0047] 2) Mixing process

[0048] When mixing at high speed, the additive penetrates into the voids of the PVC resin, so that the additive is evenly dispersed in the resin. Considering that the temperature above 1000°C is conducive to the evaporation of water vapor in the material, the temperature of the heat mixer is set at 100-1200°C ; In order to allow the additive to fully contact with the PVC particles and reduce the adsorption of the filler to the additive, the heat mixer should be started immediately after adding the PVC resin.

[0049] Add stabilizer at a t...

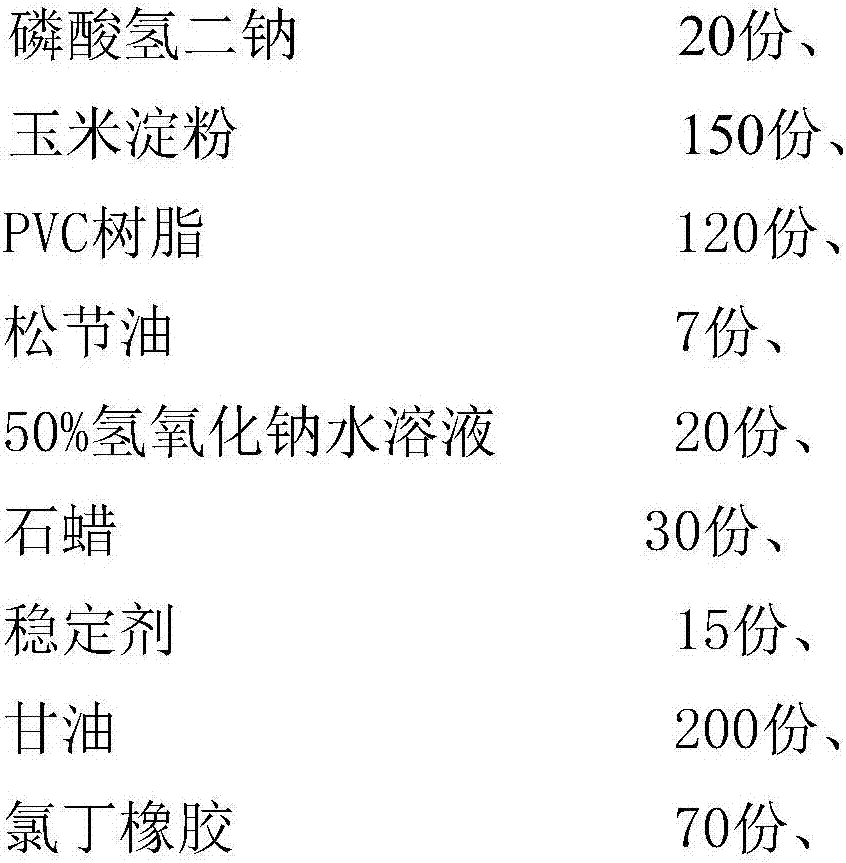

Embodiment 2

[0083] Embodiment 2: A PVC pipe extrusion molding process that effectively improves impact strength. The pipe formulation includes PVC resin, impact modifier, stabilizer, processing modifier, filler, colorant and external lubricant, specifically including Prepared by the following steps: various materials-weighing-kneading-extrusion granulation-extrusion molding-cooling molding-cutting-inspection-finished product;

[0084] 3) Mixing process

[0085] When mixing at high speed, the additive penetrates into the voids of the PVC resin, so that the additive is evenly dispersed in the resin. Considering that the temperature above 1000°C is conducive to the evaporation of water vapor in the material, the temperature of the heat mixer is set at 100-1200°C ;In order to allow the additive to fully contact with the PVC particles and reduce the adsorption of the filler to the additive, the heat mixer should be started immediately after adding the PVC resin;

[0086] Add stabilizer at tem...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Impact strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com