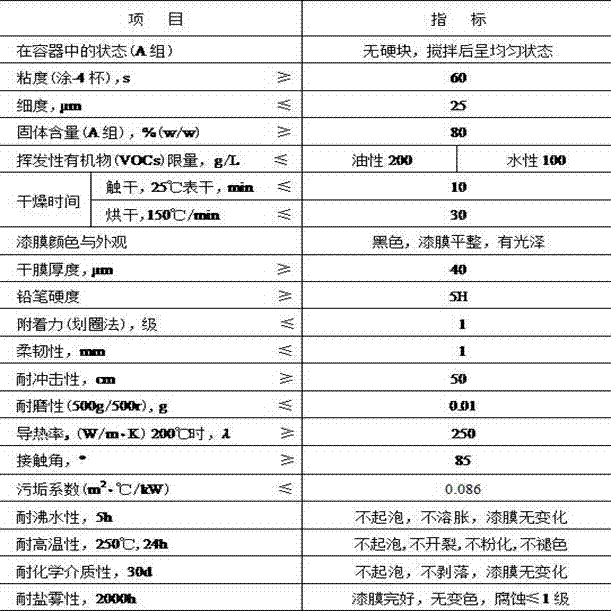

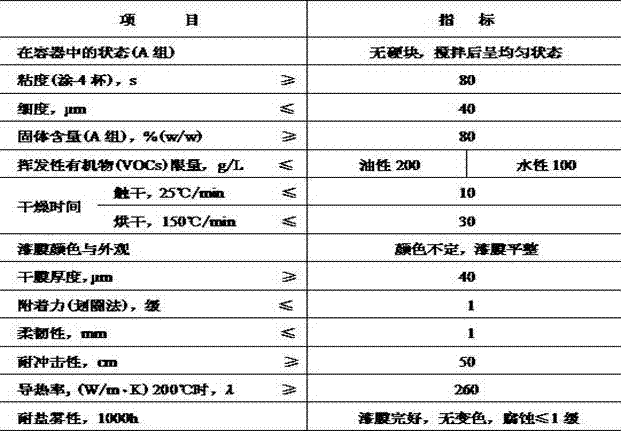

Preparation method of graphene modified high-solid-content high-temperature-resistant epoxy heat-conducting functional coating

A graphene modification and functional coating technology, applied in epoxy resin coatings, anti-corrosion coatings, fire-retardant coatings, etc., can solve the problems of unreachable, large thermal resistance, and insufficient high temperature resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] 1. Preparation of few-layer graphene dispersion slurry:

[0024] At room temperature, take 150 mg of Grafguard 160-50N by mass, and irradiate with 60 Hz, 900 W microwave for 10 to 60 s under the protection of nitrogen atmosphere to obtain microwave expansion-treated graphite.

[0025] Dissolve an appropriate amount of CTAB in 300 mL of deionized water to prepare an 8.3 mg / mL CTAB aqueous solution.

[0026] Take 50 mg of microwave-expanded graphite and mix it with the above CTAB aqueous solution, place it under ultrasonic conditions, and disperse for 12 to 24 hours to obtain a uniformly dispersed graphene suspension, then filter it with a microporous membrane with a pore size of 0.2 µm, and use it repeatedly. Wash with ion water, filter, centrifuge, dry, finally add AMP-95 amine neutralizer to adjust the pH to 7-9, disperse for 5 minutes, and prepare a few-layer graphene dispersion slurry with a solid content of 5-10% (hereinafter Abbreviated as GSs dispersion slurry). ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com