High-sensitivity mesh graphene/elastomer strain sensor and its preparation method

A mesh graphene, strain sensor technology, applied in graphene, chemical instruments and methods, electric/magnetic solid deformation measurement and other directions, can solve the problems of high cost, low sensor sensitivity, easy structure damage, etc., to improve the service life , Widen the scope of application, high repeatability effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Step 1: disperse graphite oxide in an aqueous solution, and ultrasonicate at 40 kHz for 3 hours to obtain a graphene oxide dispersion liquid with a single-sheet dispersion concentration of 0.5 mg / mL.

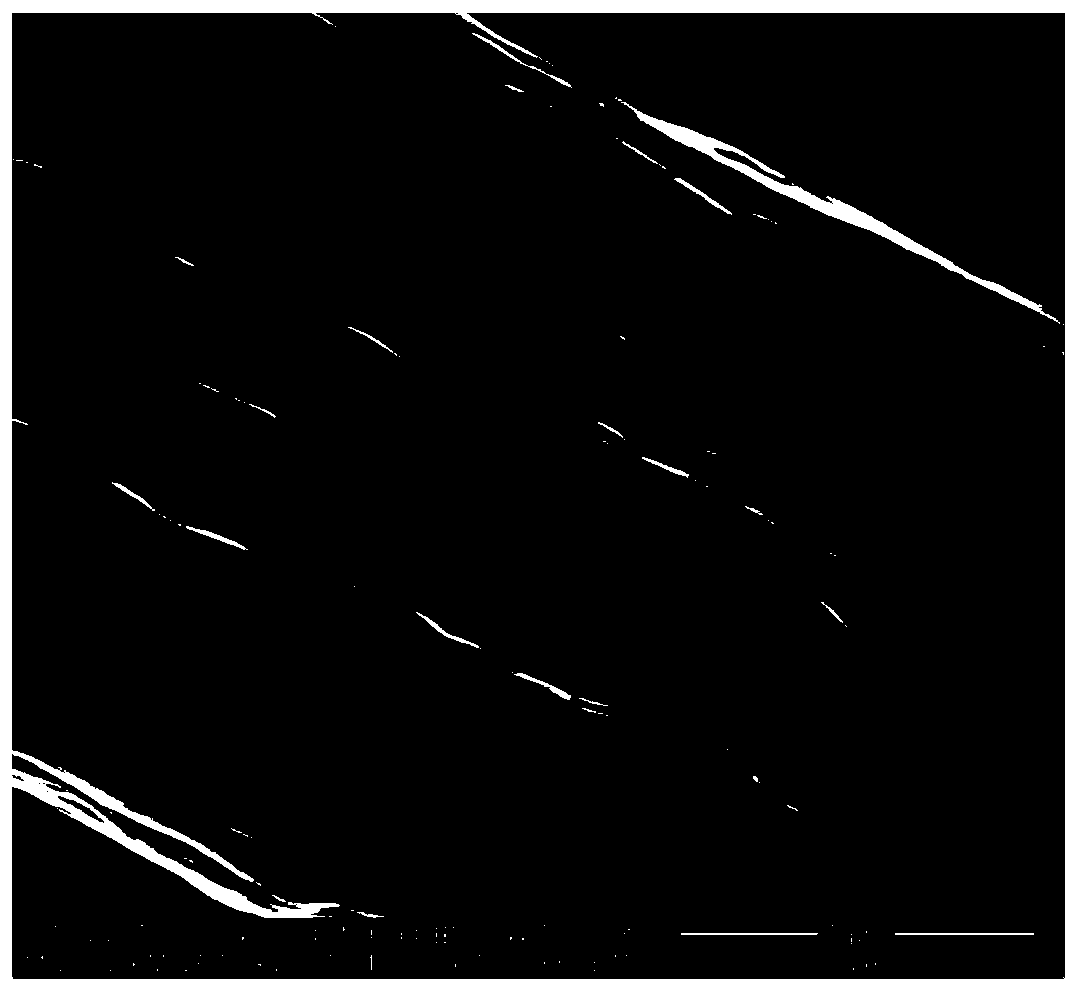

[0028] Step 2: Use the absorbent cotton bandage as a template, wash it three times with deionized water and ethanol alternately, dry it in an oven at 80°C, and soak the absorbent cotton bandage in the graphene oxide dispersion while maintaining a vacuum pressure of -0.05MPa , soaked for 0.5h, took out the absorbent cotton bandage, put it in an oven at 60°C for 2h, then transferred it to an oven at 80°C, and dried it for 1h to obtain a graphene oxide-coated absorbent cotton bandage. The sample obtained above is heated at 250° C. to 310° C. for 3 hours, and then heated at 750° C. to 850° C. for 1 hour to obtain 1 nm network graphene. The network structure of graphene is as follows: figure 1 shown.

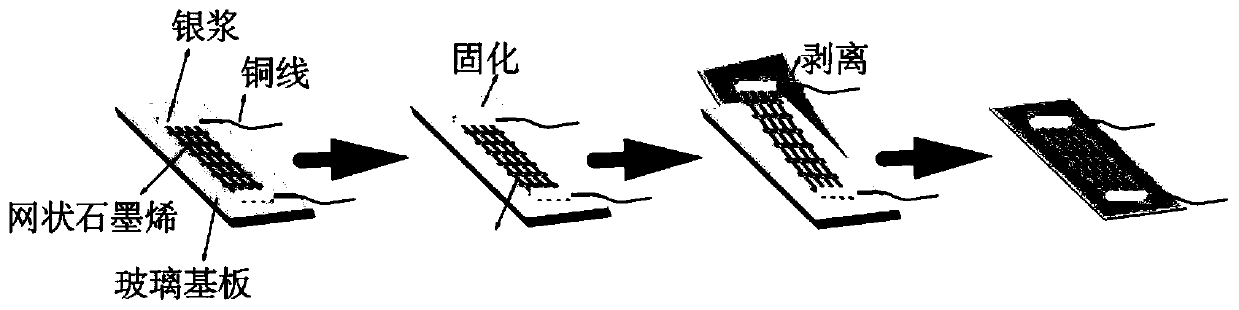

[0029] Step 3, place the graphene network obtained in step 2 on a glass sl...

Embodiment 2

[0032] Repeat embodiment 1 method, but in step one, ultrasonic power is 80kHz, and ultrasonic time is 2h, and the graphene oxide concentration that obtains is 2mg / mL; In step two, soaking time is 1h, and the graphene network thickness that obtains is 2nm; in step 3, the elastomer emulsion is styrene-butadiene rubber and natural rubber, the volume ratio is 1:1, the curing temperature is 60°C, and the curing time is 5h.

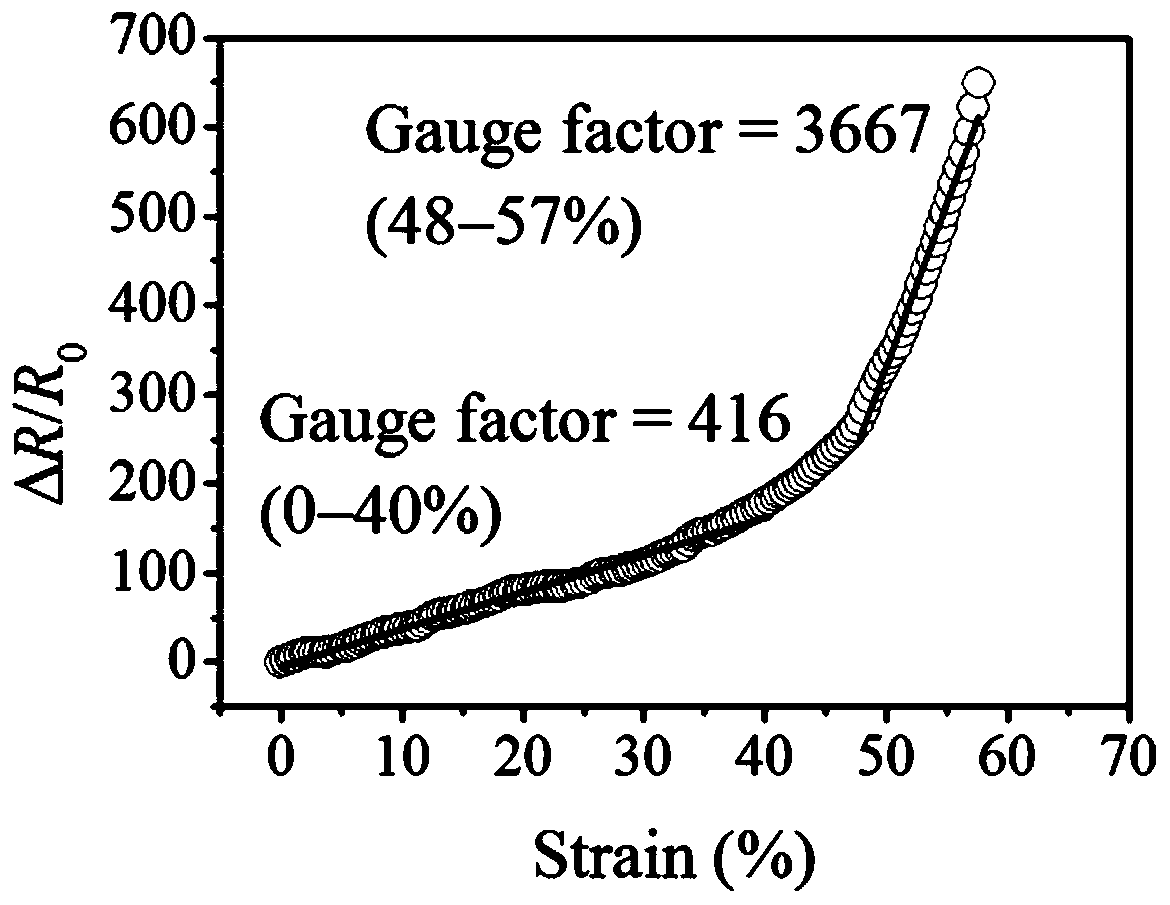

[0033] The sensitivity index Gaugefactor (GF) of the sensor is about 390 (00 ) / R 0 Δε, where R represents the resistance before deformation, R 0 Indicates the resistance after deformation, and Δε indicates the strain). When the strain is 7.5% and 50%, after repeated 50 times, the sensitivity indexes are 389 and 3576 respectively.

Embodiment 3

[0035] Repeat embodiment 1 method, but in step one, ultrasonic power is 100kHz, and ultrasonic time is 1h, and the graphene oxide concentration that obtains is 3mg / mL; In step two, soaking time is 2h, and the graphene network thickness that obtains is 3nm; in step 3, the elastomer emulsion is carboxylated nitrile rubber, the curing temperature is 80° C., and the curing time is 2 hours.

[0036] The sensitivity index Gaugefactor (GF) of the sensor is about 400 (00 ) / R 0 Δε, where R represents the resistance before deformation, R 0 Indicates the resistance after deformation, and Δε indicates the strain). When the strain is 7.5% and 50%, after repeated 50 times, the sensitivity indexes are 390 and 3600 respectively.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com