Blending method for enriching gold and silver in cupel through fire assaying

A technology of fire test gold and gray dish, which is applied in the field of analytical chemistry, can solve the problems of low accuracy of high-grade samples, achieve the effect of solving the limitation of weighing weight, improving the capture rate and saving the detection cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

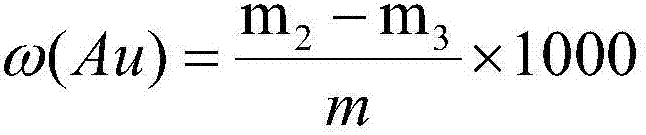

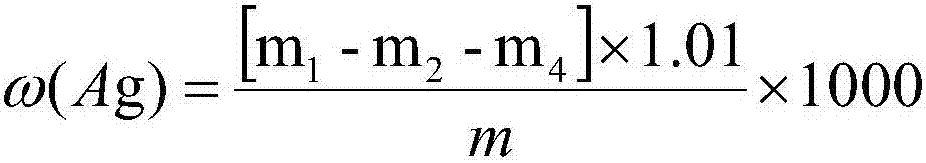

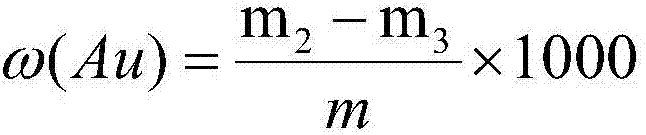

Method used

Image

Examples

Embodiment 1

[0041] Determination of gold and silver blank values in reagents according to GB / T 7739.1-2007.

[0042] Weigh 20g of gold concentrate sample, wrap it with 7g of lead skin, put it into the ash dish preheated in the furnace at 950°C for 20 minutes, close the furnace door for 2 minutes, open the furnace door slightly, quickly cover the ash dish with 15g of lead cap, and close the furnace Open the door for 3 minutes, after the molten lead is demoulded, half open the furnace door, and control the furnace temperature at 850°C, close the furnace door when the dazzling color phenomenon occurs, raise the temperature to 880°C, blow out all the lead, and move the ash dish to the furnace door , put it aside for 1min, take it out and cool it down, and get the gold-silver pellets, and at the same time, break the ash dish for later use;

[0043] Put 35g of sodium carbonate, 25g of borax, 70g of glass powder, 55g of lead oxide, 3.5g of flour and the broken ash dish into the test gold cruci...

Embodiment 2

[0056] Determination of gold and silver blank values in reagents according to GB / T 7739.1-2007.

[0057] Weigh 500.00 mg of gold mud sample, wrap it with 10 g of lead skin, put it into the ash dish preheated in the furnace at 950 ° C for 20 minutes, close the furnace door for 2 minutes, open the furnace door slightly, quickly cover the ash dish with 20 g of lead cap, and close the furnace door 5min, after the molten lead is removed from the mold, half open the furnace door, and control the furnace temperature at 930°C, close the furnace door when the phenomenon of dazzling color occurs, raise the temperature to 950°C, keep it warm for 5min, close it to blow out all the lead, and move the ash dish To the furnace door, place for 1min, take it out and cool it down, get the gold and silver granules, and at the same time, break the ash dish for later use;

[0058] Put 30g of sodium carbonate, 25g of borax, 70g of glass powder, 50g of lead oxide, 4.5g of flour and the broken ash d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com