Low resistivity CaMnO3 composite thermoelectric material preparation method

A technology of thermoelectric materials and low resistivity, which is applied in the manufacture/processing of thermoelectric devices, and lead wire materials of thermoelectric device nodes, etc. It can solve the problems of long preparation time, high production cost, and high resistivity of thermoelectric materials, so as to reduce production Cost, production time reduction, effect of reducing resistivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

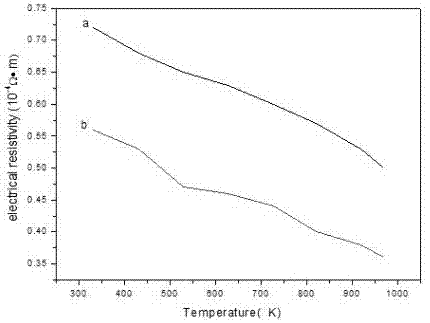

Image

Examples

Embodiment 1

[0031] Embodiment 1, a kind of low resistivity CaMnO 3 A method for preparing a composite thermoelectric material, the specific steps of the method are as follows:

[0032] (1) Dissolve calcium nitrate and manganese nitrate in water at a molar ratio of Ca:Mn=1:1 to obtain 1mol L of calcium nitrate and manganese nitrate -1 mixed solution, and then NH 4 HCO 3 The solution was added to the calcium-manganese mixed nitrate solution, and reacted under the reaction conditions of a reaction temperature of 50°C and a stirring speed of 500r / min until the precipitation was complete to obtain product A;

[0033] (2) Precipitate and age product A for 1 hour, filter and wash, and dry at 100°C to obtain product B;

[0034] (3) Mix bismuth metal and product B at a molar ratio of bismuth metal: product B = 1:25, and grind for 9 hours to obtain product C;

[0035](4) Pre-fire product C in a sintering furnace at 900°C for 9 hours, then put it into a mold, and press it under a pressure of 9 M...

Embodiment 2

[0037] Embodiment 2, a kind of low resistivity CaMnO 3 A method for preparing a composite thermoelectric material, the specific steps of the method are as follows:

[0038] (1) Dissolve calcium nitrate and manganese nitrate in water at a molar ratio of Ca:Mn=1:0.5 to obtain 1mol L of calcium nitrate and manganese nitrate -1 mixed solution, and then NH 4 HCO 3 The solution was added to the calcium-manganese mixed nitrate solution, and reacted under the reaction conditions of a reaction temperature of 40°C and a stirring speed of 600r / min until the precipitation was complete to obtain product A;

[0039] (2) Precipitate and age product A for 0.5 hours, filter and wash, and dry at 80°C to obtain product B;

[0040] (3) Mix metal bismuth and product B at a molar ratio of metal bismuth: precursor powder = 1:10, grind for 6 hours to obtain product C;

[0041] (4) Pre-fire product C in a sintering furnace at 850°C for 11 hours, then put it into a mold, and press it under a pressu...

Embodiment 3

[0043] Embodiment 3, a kind of low resistivity CaMnO 3 A method for preparing a composite thermoelectric material, the specific steps of the method are as follows:

[0044] (1) Dissolve calcium nitrate and manganese nitrate in water at a molar ratio of Ca:Mn=1:1.5 to obtain 1mol L of calcium nitrate and manganese nitrate -1 mixed solution, and then NH 4 HCO 3 The solution was added to the calcium-manganese mixed nitrate solution, and reacted under the reaction conditions of a reaction temperature of 60°C and a stirring speed of 400r / min until the precipitation was complete, and product A was obtained;

[0045] (2) Precipitate and age product A for 2 hours, filter and wash, and dry at 120°C to obtain product B;

[0046] (3) Mix bismuth metal with product B at a molar ratio of bismuth metal: precursor powder = 1:50, grind for 6 hours, and obtain product C;

[0047] (4) Pre-sinter product C in a sintering furnace at 950°C for 7 hours, then put it into a mold, and press it und...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com