Warm mixed modified asphalt, mixture containing warm mixed modified asphalt and their preparation methods

A technology of modified asphalt and mixture, which is applied in building insulation materials, organic chemistry, hydrogenation hydrocarbon production, etc., and can solve problems such as poor thermal stability and anti-aging performance, high service temperature, and environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

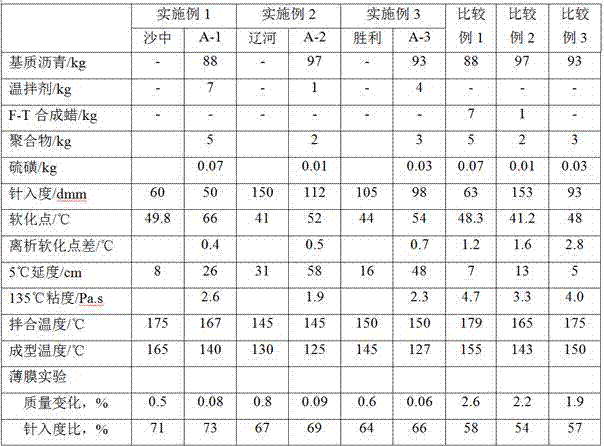

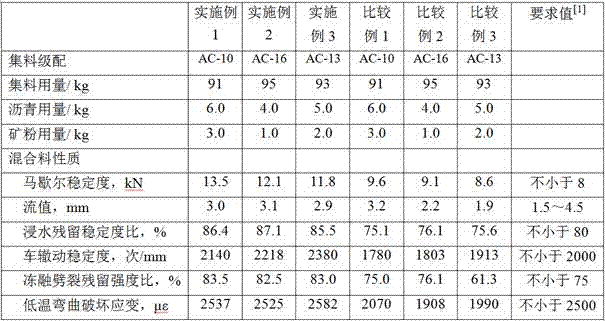

Examples

Embodiment 1

[0071] (A) Preparation of warm mix agent

[0072] Including (1) hydroconversion and (2) sweating.

[0073] (1) Hydroconversion

[0074] Using the wax oil product (n-paraffin content: 95.5wt%; drop melting point: 86.2°C; penetration (25°C) 55 dmm) from the low-temperature F-T synthesis experimental device of China Petroleum & Chemical Corporation as raw material, the FHJ-2 catalyst ( A Ni / Al 2 o 3 Commercial catalyst, developed and produced by Fushun Petrochemical Research Institute, with an active metal content of 40% in terms of oxides, and the catalyst is subjected to conventional reduction treatment before use), under the action of reaction pressure 6.5MPa, reaction temperature 220°C, volume space velocity 1.0h -1 Hydrogenation is carried out under the condition of 500:1 volume ratio of hydrogen to liquid to convert olefins and oxygenates therein.

[0075] Properties of hydrogenation products: n-paraffin weight content 97.36%; drop melting point 85.0°C; penetration (25°...

Embodiment 2

[0097] (A) Preparation of warm mix agent

[0098] This embodiment includes: (1) hydroconversion and (2) sweating.

[0099] (1) Hydroconversion

[0100] Using the wax oil product (n-paraffin content: 90.0wt%; drop melting point: 82.6°C; penetration (25°C) 62 dmm) from the low-temperature F-T synthesis experimental device of China Petroleum & Chemical Corporation as raw material, the catalyst (Mo-Ni / Al 2 o 3 , the active metal content is 20% in terms of oxides), under the action of reaction pressure 3.0MPa, reaction temperature 300℃, volume space velocity 2.0h -1 Hydrogenation is carried out under the condition of 100:1 volume ratio of hydrogen to liquid to convert olefins and oxygenates therein.

[0101] Properties of hydrogenation products: n-paraffin weight content 93.3%; drop melting point 80.6°C; penetration (25°C) 65 dmm; chromatography-mass spectrometry analysis, no alcohol, alkene, acid and other substances were detected.

[0102] It can be seen that the oxygenated...

Embodiment 3

[0124] (A) Preparation of warm mix agent

[0125] Including (1) hydroconversion and (2) sweating.

[0126] (1) Hydroconversion

[0127] Using the wax oil product (n-paraffin content: 85.5wt%; drop melting point: 80.6°C; penetration (25°C) 65 dmm) from the low-temperature F-T synthesis experimental device of China Petroleum & Chemical Corporation as raw material, the catalyst (W-Ni / Al 2 o 3 , the active metal content is 70% based on oxides), under the action of reaction pressure 10.0MPa, reaction temperature 150℃, volume space velocity 0.2h -1 Hydrogenation is carried out under the condition of 990:1 volume ratio of hydrogen to liquid to convert olefins and oxygenates therein.

[0128] Properties of hydrogenation products: n-paraffin weight content 90.3%; drop melting point 77.0°C; penetration (25°C) 66 dmm; chromatography-mass spectrometry analysis, no alcohol, alkene, acid and other substances were detected.

[0129] It can be seen that the oxygenated compounds in the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| drop melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com