Synthetic method of metal Co-loaded N-doped three-dimensional porous carbon material having excellent electrocatalytic oxygen reduction performance

A three-dimensional porous, synthetic method technology, applied in nanotechnology, circuits, electrical components, etc. for materials and surface science, can solve problems such as industrialization difficulties, immature technology, and high price, and achieve good reduction performance and wide Application prospect, low price effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0026] A method for synthesizing a Co-supported N-doped three-dimensional porous carbon material with excellent electrocatalytic oxygen reduction performance, comprising the steps of:

[0027] 1) Dissolve 200 parts of ZIF-67 and 2000 parts of [VEIm][BF4] in 30 parts of anhydrous N,N-dimethylformamide solution, after ultrasonic dispersion; add 10 parts of 2,2'-azo For bis(isobutyronitrile), continue to sonicate for 5-30 minutes; pass nitrogen gas into the above solution for 10-60 minutes; seal the obtained solution, transfer it to an oil bath at 40-80°C, and stop stirring for 1-8 hours reaction;

[0028] 2) Pour the solution in step 1) into the acetone solution, obtain the precipitate by centrifugation and suction filtration, place the precipitate in a vacuum drying oven, and grind it to obtain a powder product after drying;

[0029] 3) Put the powder product in step 2) into a quartz boat, heat up to 600-900°C in a tube furnace under a nitrogen atmosphere, and maintain the tem...

Embodiment 1

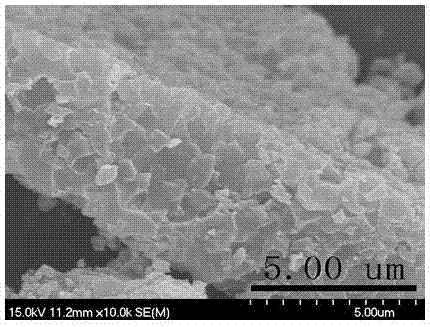

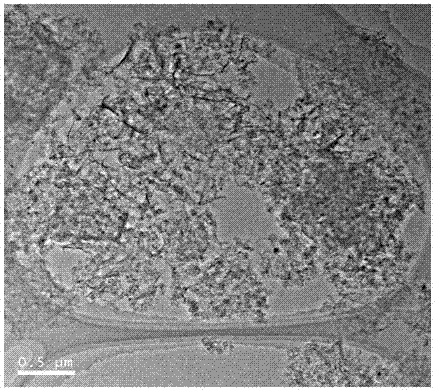

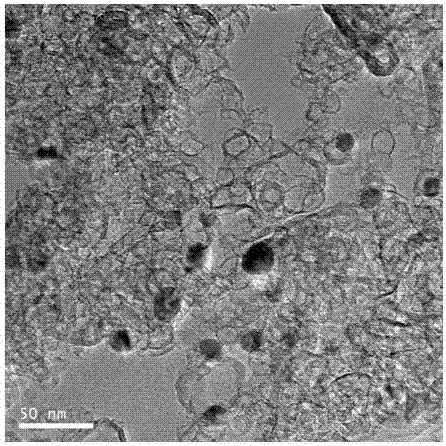

[0034] Preparation of metal Co-supported N-doped three-dimensional porous carbon material Co@NPC-700:

[0035] Measure 30mL of anhydrous N,N-dimethylformamide solution (DMF) into a 100mL flask, and equip a stirring bar, add 200mg of ZIF-67 and 2000mg of [VEIm][BF4] into it, ultrasonically wait for ZIF-67 to disperse After homogenization, 10 mg of 2,2'-azobis(isobutyronitrile) was added thereto, and ultrasound was continued for 10 minutes. Next, nitrogen gas was passed through the above solution for 30 minutes to drive away the air dissolved in the solution. After the aeration is completed, seal the flask, transfer it to a preheated oil bath, and stop the reaction after stirring continuously at 65°C for 3 hours. After the reaction solution is cooled, pour it into 300mL acetone solution, centrifuge and filter to obtain a solid product. The product was dried in a vacuum oven at 60°C for 12 hours, then taken out, and ground to obtain the complex ZIF-67@PILs. Spread ZIF-67@PILs ...

Embodiment 2

[0038] Preparation of metal Co-supported N-doped three-dimensional porous carbon material Co@NPC-600:

[0039]Measure 30mL of anhydrous N,N-dimethylformamide solution (DMF) into a 100mL flask, and equip a stirring bar, add 200mg of ZIF-67 and 2000mg of [VEIm][BF4] into it, ultrasonically wait for ZIF-67 to disperse After homogeneity, add 10 mg of 2,2'-azobis(isobutyronitrile) to it, and continue to sonicate for 10 minutes. Next, nitrogen gas was passed through the above solution for 30 minutes to drive away the air dissolved in the solution. After the aeration is completed, seal the flask, transfer it to a preheated oil bath, and stop the reaction after stirring continuously at 65°C for 3 hours. After the reaction solution is cooled, pour it into 300mL acetone solution, centrifuge and filter to obtain a solid product. The product was dried in a vacuum oven at 60°C for 12 hours, then taken out, and ground to obtain the complex ZIF-67@PILs. Spread ZIF-67@PILs evenly in the qu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com