Cerium-manganese composite oxide catalyst as well as preparation method and application thereof

A composite oxide and catalyst technology, applied in catalyst activation/preparation, metal/metal oxide/metal hydroxide catalyst, physical/chemical process catalyst, etc., can solve problems such as environmental pollution and achieve high ozone catalytic decomposition activity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

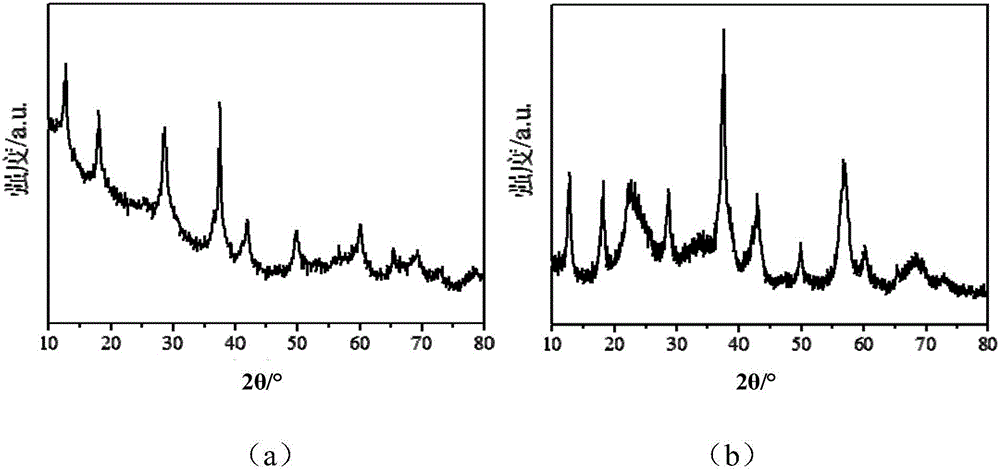

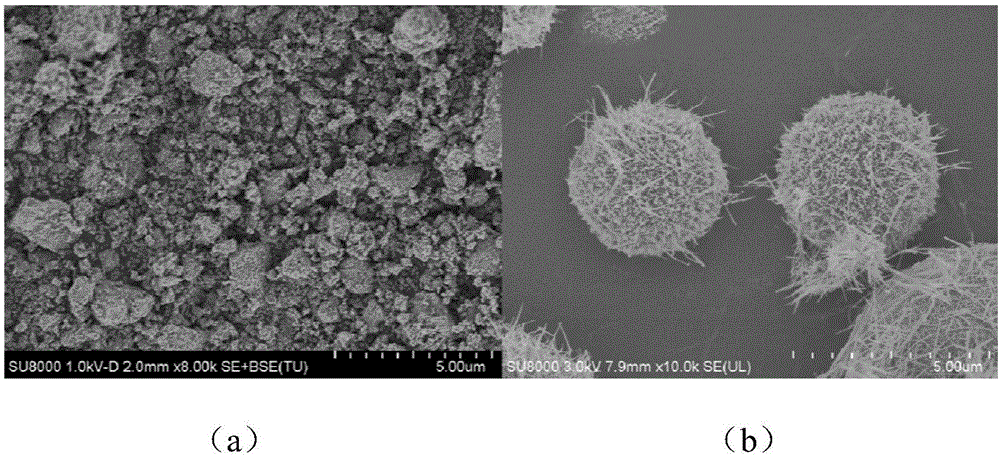

Image

Examples

Embodiment 1

[0052] A cerium-manganese composite oxide catalyst has the following chemical composition: CeMn 10 o x .

[0053] The preparation method of cerium-manganese composite oxide catalyst comprises the steps:

[0054] (1) Dissolve 3.375g of manganese sulfate in 80mL of deionized water and stir until completely dissolved;

[0055] (2) add 0.852g cerium nitrate in the solution that step (1) obtains, fully stir until solid dissolves completely, then add ammonium persulfate (concentration after ammonium persulfate dissolves completely is 45.75mg / mL) and stir for a while, After complete dissolution, transfer it to a 100mL high-pressure hydrothermal kettle, and conduct a hydrothermal reaction at 90°C for 24 hours; cool the hydrothermal reaction product to room temperature, filter and wash until neutral, and dry at 80°C for 12 hours to obtain a solid product;

[0056] (3) Calcining the solid product at 300° C. for 2 hours to obtain the cerium-manganese composite oxide catalyst.

[0057...

Embodiment 2

[0064] A cerium-manganese composite oxide catalyst has the following chemical composition: CeMn 15 o x .

[0065] Its preparation method is the same as the preparation method described in Example 1 except that the mass ratio of manganese sulfate to cerium nitrate is 6:1.

Embodiment 3

[0067] A cerium-manganese composite oxide catalyst has the following chemical composition: CeMn 20 o x .

[0068] Its preparation method is the same as the preparation method described in Example 1 except that the mass ratio of manganese sulfate to cerium nitrate is 8:1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

| decomposition efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com