Alpha-phase fusiform porous ferric oxide material and preparation method and application thereof

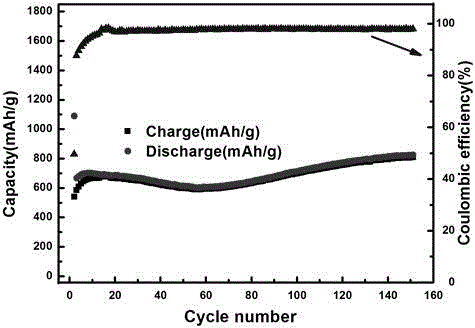

A ferric oxide and shuttle-shaped technology, which is applied in the field of α-phase shuttle-shaped porous ferric oxide material and its preparation, can solve the problems of poor cycle life and achieve improved cycle life, easy implementation, and good reproducibility Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] (1) 0.649g ferric chloride and 0.649g fumaric acid were added to a beaker filled with 16ml dimethylformamide and stirred continuously until all dissolved;

[0027] (2) Place the mixed dimethylformamide solution in step (1) in a 20 mL autoclave, then place it in an oven for solvothermal treatment, keep it at 80°C for 4 hours, and then cool it naturally to room temperature;

[0028] (3) Centrifuge the sample after solvoheating in step (2) at a speed of 5000 r / min and wash it with ethanol 4 times; finally put the precipitate in a vacuum drying machine for drying at 80°C to obtain an iron-based metal-organic framework Nanofibers;

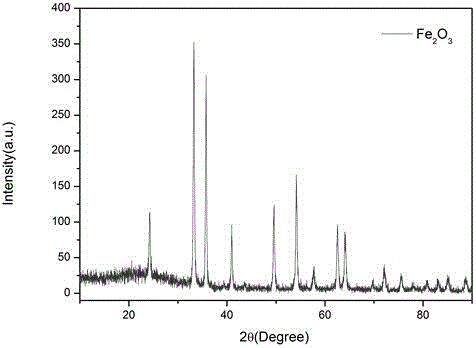

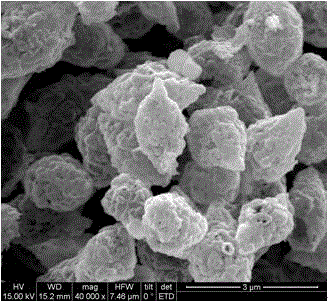

[0029] (4) Place the iron-based metal-organic framework nanofibers dried in step (3) in a tube furnace, and feed air protection gas at an air intake rate of 0.15 L / min. The heating rate is 2 °C / min, and the temperature is raised to 500°C and heat preservation for 4 hours, then naturally cooled to room temperature to obtain the α-phase shuttle-sh...

Embodiment 2

[0033] (1) 0.779 g of ferric nitrate and 0.389 g of fumaric acid were added to a beaker filled with 16 ml of dimethylformamide and stirred continuously until all dissolved;

[0034] (2) Place the mixed dimethylformamide solution in step (1) in a 20 mL autoclave, then place it in an oven for solvothermal treatment, keep it at 80°C for 4 hours, and then cool it naturally to room temperature;

[0035] (3) Centrifuge the sample after solvothermal in step (2) at a speed of 6500 r / min and wash it with ethanol for 4 times; finally put the precipitate in a vacuum drying machine for drying at 80°C to obtain an iron-based metal-organic framework Nanofibers;

[0036](4) Place the iron-based metal-organic framework nanofibers dried in step (3) in a tube furnace, and feed air protection gas at an air intake rate of 0.3 L / min. The heating rate is 3°C / min, and the temperature is raised to 500°C and heat preservation for 4 hours, then naturally cool to room temperature to obtain α-phase poro...

Embodiment 3

[0039] (1) 0.724 g of ferric sulfate and 0.483 g of fumaric acid were added to a beaker filled with 16 ml of dimethylformamide and stirred continuously until all dissolved;

[0040] (2) Place the mixed dimethylformamide solution in step (1) in a 20 mL autoclave, then place it in an oven for solvothermal treatment, keep it at 80°C for 4 hours, and then cool it naturally to room temperature;

[0041] (3) Centrifuge the sample after solvothermal in step (2) at a speed of 8000 r / min and wash it with ethanol for 4 times; finally put the precipitate in a vacuum drying machine for drying at 80°C to obtain an iron-based metal-organic framework Nanofibers;

[0042] (4) Place the iron-based metal-organic framework nanofibers dried in step (3) in a tube furnace, and feed air protection gas at an air intake rate of 0.4 L / min. The heating rate is 5°C / min, and the temperature is raised to 500°C and heat preservation for 4 hours, then naturally cooled to room temperature to obtain the α-pha...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| retention rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com