Lanjun glaze

A Jun glaze and raw material technology, applied in the field of Lan Jun glaze and its preparation, can solve the problems of monotonous atmosphere, lack of simple and elegant style, monotonous and gorgeous glaze color of Lan Jun glaze, etc., and achieve economic and artistic value, high yield, The effect of expanding the firing range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

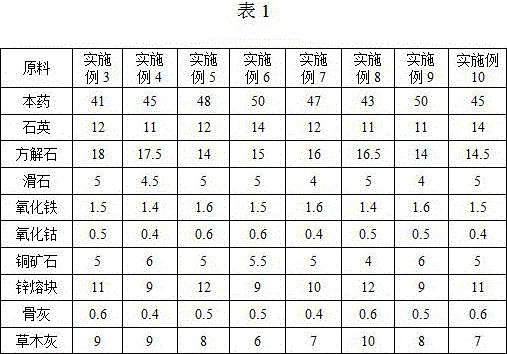

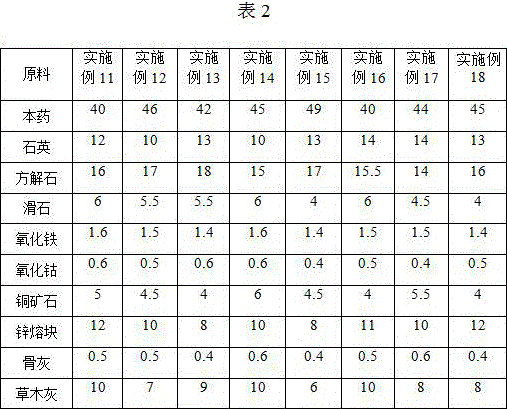

[0017] A Lanjun glaze prepared from the following raw materials in parts by weight: 40-50 parts of this medicine, 10-14 parts of quartz, 14-18 parts of calcite, 4-6 parts of talc, 1.4-1.6 parts of iron oxide, cobalt oxide 0.4-0.6 parts, 4-6 parts of copper ore, 8-12 parts of zinc frit, 0.4-0.6 parts of ashes, 6-10 parts of plant ash. The zinc content in the zinc frit is greater than 15%.

[0018] The preparation method of above-mentioned Lan Jun glaze comprises the following steps:

[0019] (1) Mix the above raw materials with water and ball mill to obtain a glaze slurry; the mass concentration of the glaze slurry is 54-56%;

[0020] (2) Apply glaze by dipping method, and dip glaze twice;

[0021] (3) Firing with coal or charcoal, the specific firing steps are as follows: ① Oxidation stage: put the glazed green body into the kiln, and fire in an oxidizing atmosphere, so that the temperature rises evenly to 1000-1050°C; ②Reduction stage: Under a reducing atmosphere, the temp...

Embodiment 2

[0024] A Lanjun glaze prepared from the following raw materials in parts by weight: 45 parts of this medicine, 12 parts of quartz, 16 parts of calcite, 5 parts of talc, 1.5 parts of iron oxide, 0.5 part of cobalt oxide, 5 parts of copper ore, zinc 10 parts of frit, 0.5 part of ashes, and 8 parts of plant ash.

[0025] The preparation method of above-mentioned Lan Jun glaze comprises the following steps:

[0026] (1) Mix the above raw materials with water and ball mill to obtain a glaze slurry; the mass concentration of the glaze slurry is 55%;

[0027] (2) Apply glaze by dipping method, and dip glaze twice;

[0028] (3) Firing with coal or charcoal, the specific firing steps are as follows: ① Oxidation stage: put the glazed green body into the kiln, and fire in an oxidizing atmosphere, so that the temperature rises evenly to 1020°C in 5 hours ; ②Reduction stage: Under a reducing atmosphere, the temperature is evenly raised to 1260-1300°C in 5-6h; ③Cooling stage: natural cool...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com