Manufacturing method of optical window structure adopting hermetic packaging of sapphire lens and kovar

A manufacturing method, sapphire technology, is applied in the field of light window structure manufacturing of sapphire lens and Kovar alloy airtight package, which can solve the problem that the airtightness and firmness cannot be well realized, and the airtightness of the sealing parts is affected. Reliability, affecting the service life of sealing parts and other issues, to achieve the effect of easy surface finish, easier realization of welding process, and good processing and forming performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

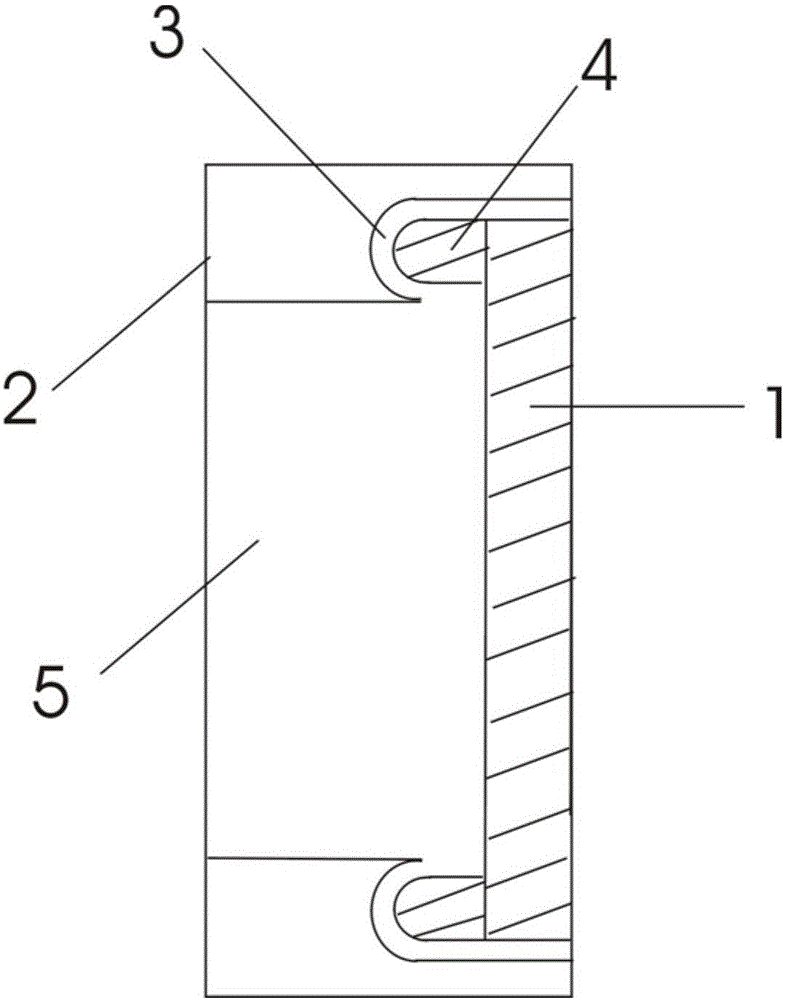

[0024] Embodiment 1: A method for manufacturing a light window structure of a sapphire lens and a Kovar alloy hermetic package, comprising the following steps: (the glass solder model described in this embodiment is Mansol (L13))

[0025] (1) Sapphire lens with convex grooves: the sapphire is subjected to a series of processing such as slicing and grinding to form convex grooves around it, and polished with polishing powder to form a transparent surface.

[0026] (2) Metal molded parts with grooves: Kovar metal is molded so that a groove is formed at the seal, and the groove can be engaged with the convex groove of the sapphire lens.

[0027] (3) Pretreatment of sapphire lens sealing: cleaning, wiping and drying.

[0028] (4) Pre-sealing treatment of metal forming parts: cleaning, wiping, drying, pre-oxidation.

[0029] (5) Sealing: Clamp the solder to the groove of the metal molding with tweezers, place the sapphire window on the solder, make the convex groove of the sapphir...

Embodiment 2

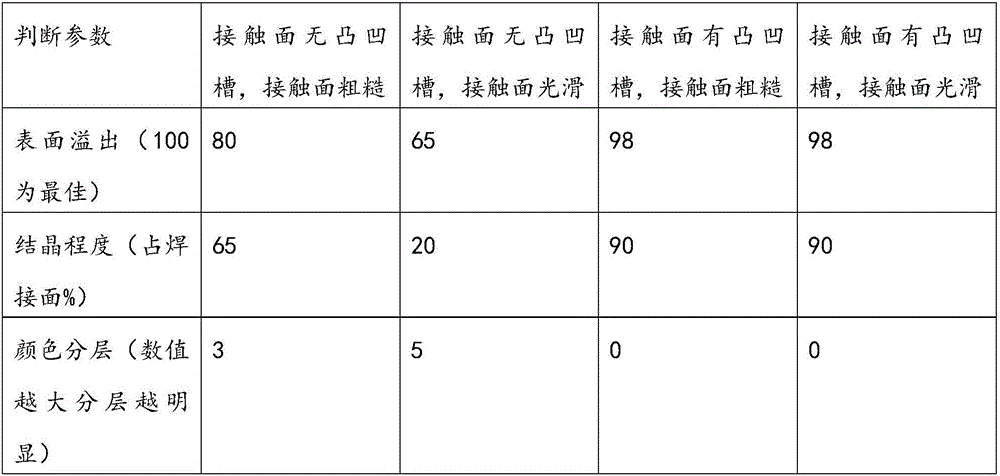

[0035] Embodiment 2: Welding effect evaluation of sapphire lens and Kovar alloy sealing

[0036] After sealing, observe the surface solder overflow condition, degree of crystallinity, and color layering of the sample under a microscope to judge the effect of welding: (the experimental object is obtained from the sealing process of Example 1, and the only variable is whether to set convex grooves)

[0037] Table 2 Whether to set the convex groove test data in the welding area

[0038]

[0039] It can be seen under the microscope that if the solder overflows, it means that the solder has completely melted and has reached the melting point of the solder. The crystalline area is calculated as the percentage of the crystalline area in the entire welding area as 100% of the entire welding surface. The higher the degree of crystallinity, the better the effect of solder welding. The color stratification indicates the uniformity of the solder after soldering. If the stratification...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com