Photosensitive resin composition, cover film and circuit board

A technology of photosensitive resin and composition, applied in the directions of printed circuit, printed circuit manufacturing, multilayer circuit manufacturing, etc., can solve the problems of increasing storage cost and deterioration risk, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0034] The preparation method of the photosensitive resin composition can be: the carboxylic acid modified bisphenol type epoxy (meth)acrylate, photosensitive monomer, photosensitive prepolymer, colorant solvent and photoinitiator etc. The ratio is added to the reaction bottle, mixed and stirred, and the carboxylic acid modified bisphenol epoxy (meth)acrylate, photosensitive monomer, photosensitive prepolymer, colorant and photoinitiator are mixed evenly, and the photosensitive resin is obtained. combination. The amount of addition of the solvent can be changed as required, as long as the carboxylic acid modified bisphenol type epoxy (meth)acrylate, photosensitive monomer, photosensitive prepolymer, colorant solvent and photoinitiator can Dissolve completely.

[0035] see figure 1 , a cover film 100 comprising a resin layer 20 and a release film 10 bonded to at least one surface of the resin layer 20 . The resin layer 20 is formed by coating the above-mentioned photosensiti...

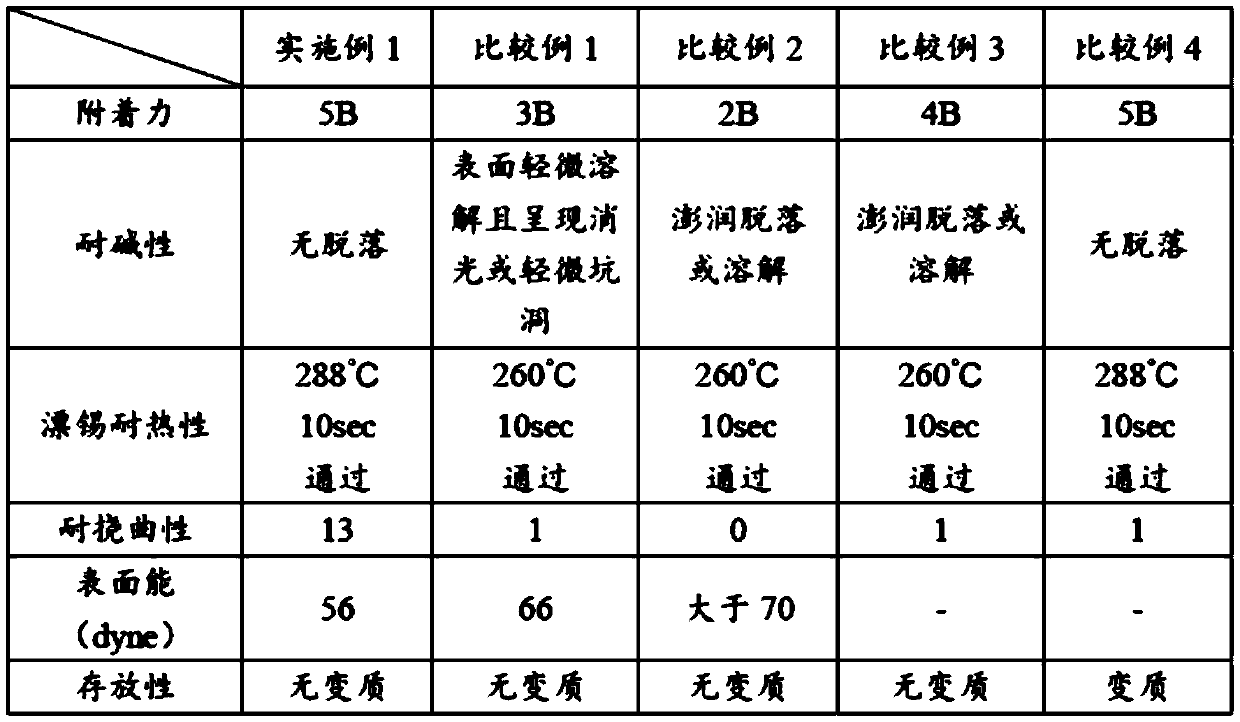

Embodiment 1

[0039] Add 100g carboxylic acid modified bisphenol type epoxy (meth)acrylate, 30g propoxylated trimethylolpropane triacrylate, 10g dipentaerythritol hexaacrylate, 20g acrylate aminomethyl in the reaction bottle of 500ml in volume Ester, 7g 2-methyl-1-(4-methylthiophenyl)-2-morpholinyl-1-propanone, 3g isopropyl thioxanthone, 2g colorant, 40g methyl ethyl ketone, stir to dissolve , that is, a photosensitive resin composition is obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com