Microemulsion type high-temperature-resistant blockage remover for sulfur-containing gas well, and preparation method thereof

A plug-removing agent and high-temperature-resistant technology, which is applied in the direction of chemical instruments and methods, drilling compositions, etc., can solve the problem that the temperature resistance does not exceed 100°C, and achieve high temperature resistance, good thermal stability, and broad The effect of applying the foreground

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

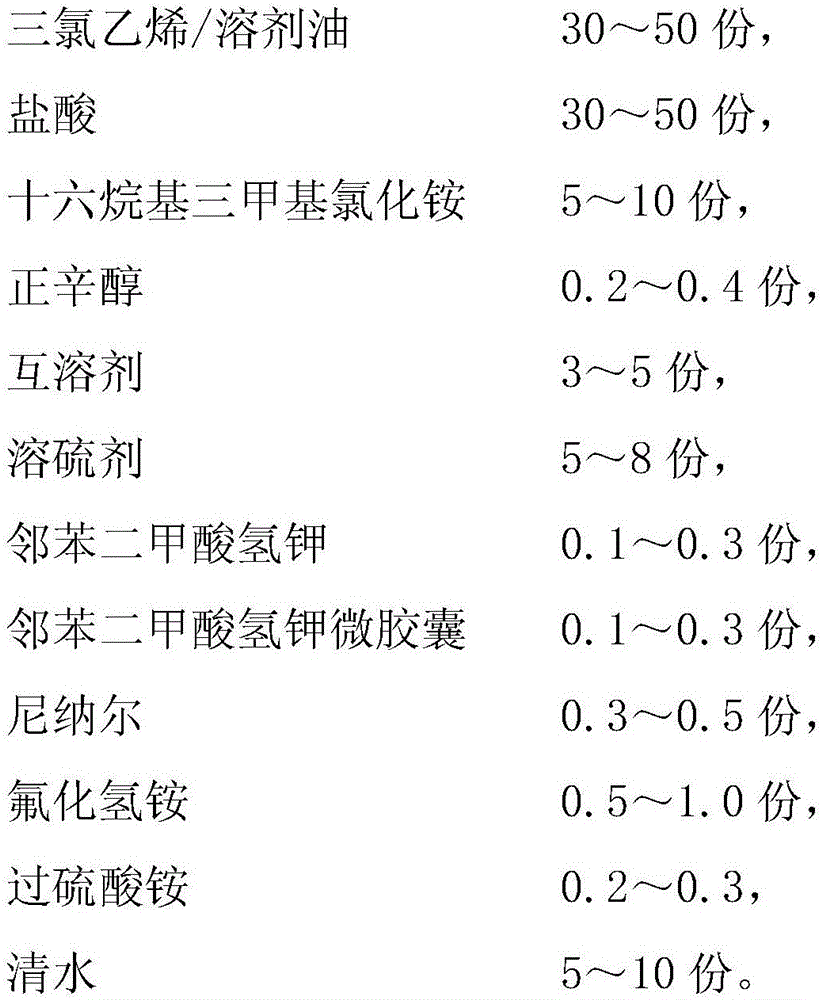

Method used

Image

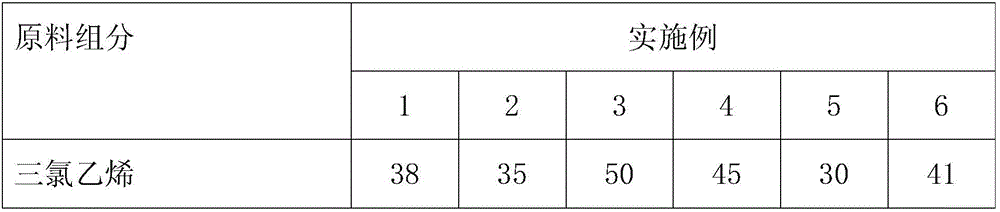

Examples

Embodiment 7

[0044] The preparation method of the present invention comprises the following sequential steps:

[0045] Step 1. Prepare constant temperature water bath equipment and heat up to 63°C to 64°C;

[0046] Each raw material is taken by the formula quantity of embodiment 1;

[0047] Step 2. Put hydrochloric acid, clear water, and potassium hydrogen phthalate into an acid-resistant container (such as a glass container, etc.), then place the acid-resistant container in a water bath, and stir evenly after each raw material in the acid-resistant container is completely dissolved;

[0048] Step 3. Add cetyltrimethylammonium chloride in the acid-resistant container; stir evenly after dissolving at the temperature of the water bath;

[0049] Step 4. The acid-resistant container of step 3 is taken out from the water bath equipment;

[0050] Add trichlorethylene (or solvent naphtha) and mutual solvent into an acid-resistant container, and stir for 10 minutes with a stirrer at a speed of 900...

Embodiment 8

[0055] The preparation method of the present invention comprises the following sequential steps:

[0056] Step 1. Prepare constant temperature water bath equipment and heat up to 68°C to 70°C;

[0057] Each raw material is taken by the formula quantity of embodiment 3;

[0058] Step 2. Put hydrochloric acid, clear water, and potassium hydrogen phthalate into an acid-resistant container, then place the acid-resistant container in a water bath, and stir evenly after the raw materials in the acid-resistant container are completely dissolved;

[0059] Step 3. Add cetyltrimethylammonium chloride in the acid-resistant container; stir evenly after dissolving at the temperature of the water bath;

[0060] Step 4. The acid-resistant container of step 3 is taken out from the water bath equipment;

[0061] Add trichlorethylene (or solvent naphtha) and mutual solvent into an acid-resistant container, and stir for 10 minutes with a stirrer at a speed of 1000 rpm;

[0062] Step 5. Add n-...

Embodiment 9

[0066] The preparation method of the present invention comprises the following sequential steps:

[0067] Step 1. Prepare constant temperature water bath equipment and heat up to 60°C to 61°C;

[0068] Each raw material is taken by the formula quantity of embodiment 4;

[0069] Step 2. Put hydrochloric acid, clear water, and potassium hydrogen phthalate into an acid-resistant container, then place the acid-resistant container in a water bath, and stir evenly after the raw materials in the acid-resistant container are completely dissolved;

[0070] Step 3. Add cetyltrimethylammonium chloride in the acid-resistant container; stir evenly after dissolving at the temperature of the water bath;

[0071] Step 4. The acid-resistant container of step 3 is taken out from the water bath equipment;

[0072] Add trichlorethylene (or solvent naphtha) and mutual solvent in the acid-resistant container, and stir for 10 minutes with a stirrer at a speed of 1200 rpm;

[0073] Step 5. Add n-o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com