Suspension roasting manganese and iron treatment method of iron-contained manganese ore

A separation treatment and suspension roasting technology, which is applied in the field of mineral processing, can solve the problems of complex process, low processing capacity and high energy consumption for blending bituminous coal.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

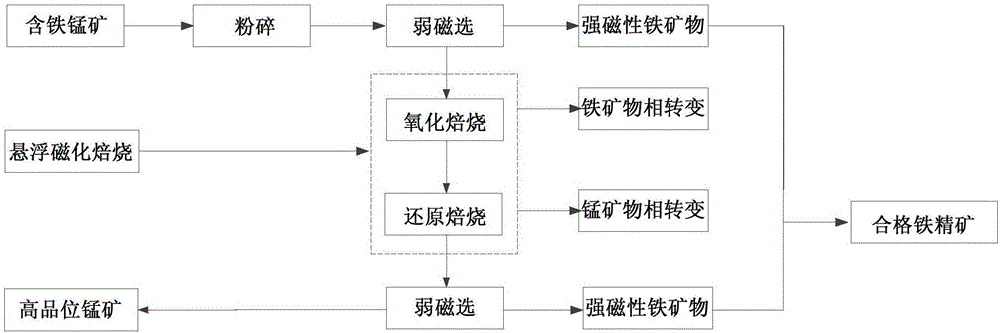

[0028] Process such as figure 1 shown;

[0029] Crush the iron-manganese ore to a particle size of 2-20 mm, and then grind the ore to a particle size of -0.074 mm, accounting for 50% of the total weight, to make fine ore;

[0030] The powder ore is subjected to a stage of weak magnetic separation, with a magnetic field strength of 2000Oe, to obtain a stage of weak magnetic separation concentrate and a stage of weak magnetic separation tailings;

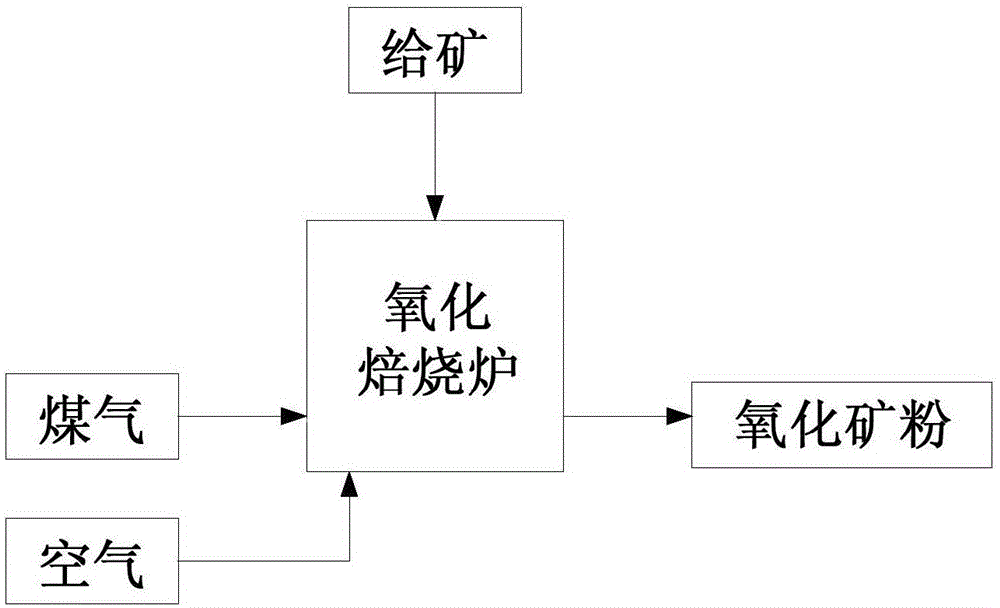

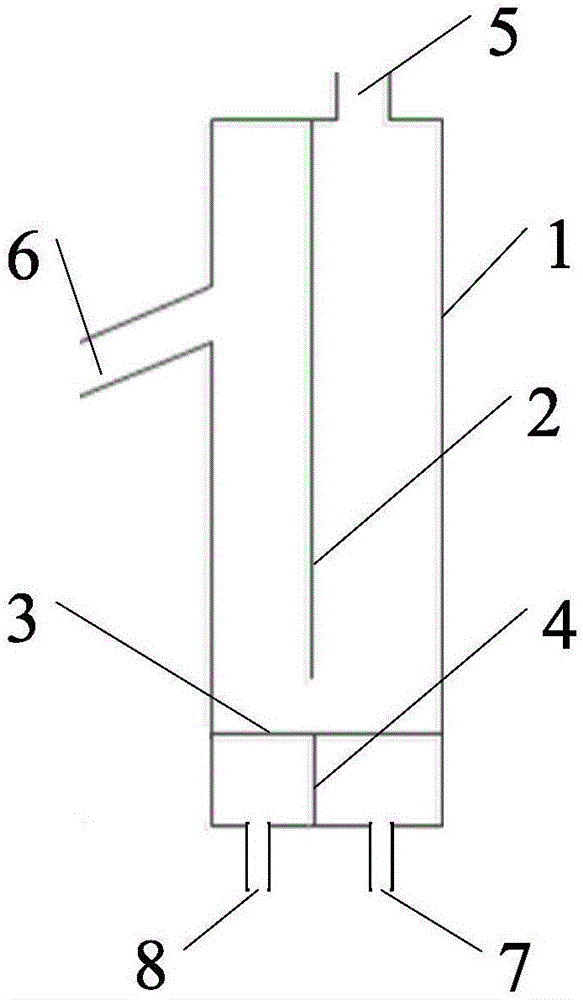

[0031] Put a section of weak magnetic separation tailings in the roasting furnace, feed gas and air to keep a section of weak magnetic separation tailings in a suspended state, and oxidize and roast a section of weak magnetic separation tailings at a roasting temperature of 800°C for a roasting time of 20 minutes. Volatilize water and other volatile components, and oxidize iron to Fe 2 o 3 , to obtain oxidized powder ore; the flow rate of gas and air is 13m per ton of weak magnetic separation tailings 3 / h; oxidation roasting proc...

Embodiment 2

[0037] Method is with embodiment 1, and difference is:

[0038] (1) Crushing the iron-manganese-containing ore to a particle size of 2-20 mm, and then grinding the ore until the part with a particle size of -0.074 mm accounts for 60% of the total weight to make fine ore;

[0039] (2) The magnetic field strength of a section of weak magnetic separation is 1800Oe;

[0040](3) Oxidation roasting temperature 900°C, time 12min, to volatilize water and other volatile components, and oxidize iron to Fe 2 o 3 , to obtain oxidized powder ore; the flow rate of gas and air is 19m per ton of weak magnetic separation tailings 3 / h;

[0041] (4) The reduction roasting temperature is 600°C, the time is 8min, and the reducing gas is H 2 , the flow rate of reducing gas is H 2 The total amount is 10m 3 / h; the ratio of nitrogen and reducing gas is 3:1;

[0042] (5) The magnetic field strength of the second-stage weak magnetic separation is 1800Oe;

[0043] (6) iron grade TFe of finished...

Embodiment 3

[0045] Method is with embodiment 1, and difference is:

[0046] (1) Crushing the iron-manganese-containing ore to a particle size of 2 to 20 mm, and then grinding the ore until the particle size of -0.074 mm accounts for 70% of the total weight to make fine ore;

[0047] (2) The magnetic field strength of a section of weak magnetic separation is 1300Oe;

[0048] (3) Oxidation roasting temperature 950°C, time 8min, to volatilize water and other volatile components, and oxidize iron to Fe 2 o 3 , to obtain oxidized powder ore; the flow rate of gas and air is 5m per ton of weak magnetic separation tailings 3 / h;

[0049] (4) The reduction roasting temperature is 700°C, and the time is 5 minutes, wherein the reduction gas is coal gas, and the flow rate of the reduction gas is based on the amount of CO and H introduced per ton of oxidized ore powder. 2 The total amount is 5m 3 / h; the ratio of nitrogen and reducing gas is 4:1;

[0050] (5) The magnetic field strength of the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com