Preparation and quality detection method of amomum para-tsaoko total flavonoids extract

A quality detection method, a technology of total flavonoids, applied in the direction of measuring devices, instruments, scientific instruments, etc., can solve the problems of non-volatile chemical components, pharmacological activity, safety, and lag in the development and utilization of Brassica fructus , to achieve the effect of reasonable, stable and feasible process conditions, reduced analysis and testing costs, and less residue

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

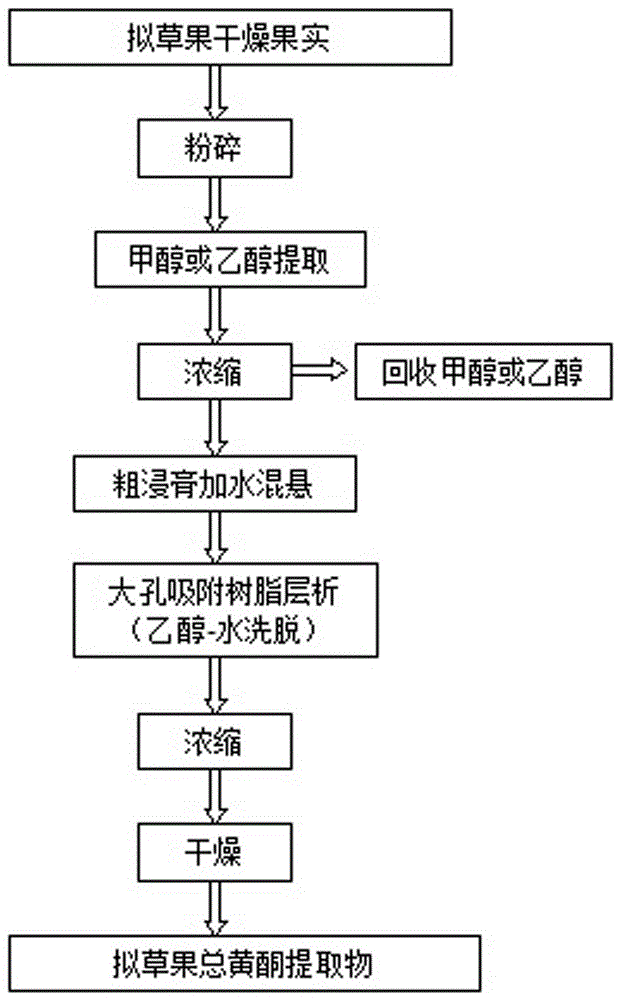

Embodiment 1

[0048] Grind the dried fruit of Brassica fructus into 200 g of coarse powder, add 10 times the weight of methanol with a volume concentration of 70% for extraction, heat and reflux in a water bath at 90°C for 3 times, each time for 1.5 hours, filter, and combine the filtrates, Recover methanol or ethanol from the filtrate and concentrate under reduced pressure without alcohol smell, add water to make up to 5000ml (concentration 0.04g crude drug amount / ml), filter through four layers of gauze until the clear liquid, filter, pass through HP-20 macroporous adsorption resin column (upper The volume of the sample liquid is 10 times the volume of the filled macroporous adsorption resin), and the flow rate of the upper column is 2 BV / h; wash with 10 times of water, and discard the washing solution to fill 15 times the volume of the macroporous adsorbent resin with a volume concentration of 30%. ethanol elution, the elution flow rate is 1BV / h; collect the eluent, concentrate the eluent...

Embodiment 2

[0050] Take the dried fruit of Brassica fructus and crush it into 500g of coarse powder, add 15 times the amount of methanol with a volume concentration of 80% according to the weight for extraction, heat and reflux extraction in a water bath at 80°C for 4 times, each time for 1 hour, filter, combine the filtrate, the filtrate Recover methanol or ethanol and concentrate under reduced pressure without alcohol smell, add water to make up to 9000 ml (0.056g medicinal materials / ml), filter through four layers of gauze until the clear liquid is filtered, and pass through HP-20 macroporous adsorption resin column (loading solution The volume is 20 times the volume of the resin), and the flow rate on the column is 2BV / h; wash with 10 times of water, discard the washing solution, and elute with ethanol with a volume concentration of 90% and 10 times the volume of the macroporous adsorbent resin, and collect the washed Ethanol was removed, and the elution flow rate was 3 BV / h; ethanol w...

Embodiment 3

[0052] Take the dried fruit of Brassica fructus and crush it into 500 g of coarse powder, add 5 times the amount of 100% methanol according to the weight to extract, heat and reflux in a water bath at 80°C for 3 times, each time for 0.5 hours, filter, combine the filtrate, and recover methanol from the filtrate Or ethanol and concentrated under reduced pressure without alcohol smell, add water to make up to 7500 ml (0.067 g medicinal material / ml), filter through four layers of gauze to a clear liquid, filter, pass through AB-8 macroporous adsorption resin column (the volume of the sample solution is 10 times the volume of the resin), and the column flow rate is 4 BV / h; wash with 10 times of water, discard the washing liquid, and elute with 15 times the volume of the macroporous adsorption resin, and the volume concentration is 70% ethanol, and the elution flow rate is 3BV / h; collect the eluent, concentrate the eluent to the extract under reduced pressure, and dry it in vacuum a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com