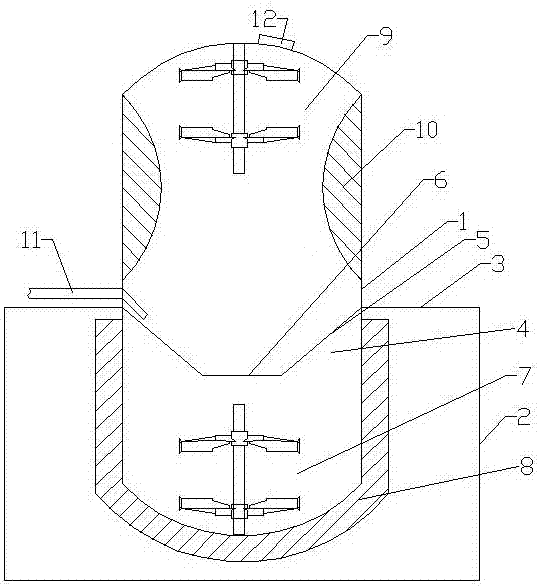

Super wear-resisting and moisture-resisting gel nano thermal insulation material and preparation method and device thereof

A nano-insulation material, super wear-resistant technology, applied in ceramic products, other household appliances, household appliances, etc., can solve the problem of high production cost, and achieve the effects of increased productivity, good thermal insulation effect and time saving.

- Summary

- Abstract

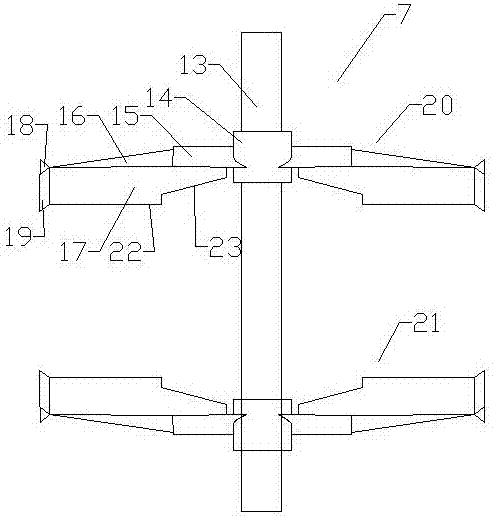

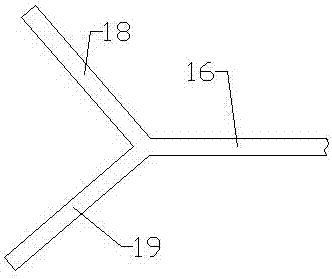

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Example 1, a super-abrasion-resistant and water-resistant airgel nano-insulation material, which is made of the following raw materials in parts by weight: 20 parts of ceramic fiber felt, 10 parts of aluminum sec-butoxide, 20 parts of ethanol, deionized water 80 parts, 3 parts of butadiene rubber, 2 parts of styrene-butadiene rubber, 8 parts of catalyst, and 3 parts of active agent.

[0032] Described catalyzer is glacial acetic acid, and described active agent is made up of nano zinc oxide and stearic acid, and wherein, the weight ratio of nano zinc oxide and stearic acid is 2.5:1 part;

[0033] The nano-zinc oxide includes primary particles with a particle size of 20 nm or less and primary particles with a particle size of 20 nm-30 nm, wherein primary particles with a particle size of 20 nm or less account for 70%, and primary particles with a particle size of 20 nm-30 nm account for 30%. %.

[0034] A preparation method of an ultra-abrasion-resistant and water-resis...

Embodiment 2

[0039] Example 2, a super wear-resistant and water-resistant airgel nano-insulation material, which is made of the following raw material ratios in parts by weight: 25 parts of ceramic fiber felt, 18 parts of aluminum sec-butoxide, 30 parts of ethanol, deionized water 100 parts, butadiene rubber 5 parts, styrene-butadiene rubber 4 parts, catalyst 15 parts, activator 5 parts.

[0040] Described catalyzer is glacial acetic acid, and described active agent is made up of nano zinc oxide and stearic acid, and wherein, the weight ratio of nano zinc oxide and stearic acid is 2.5:1 part;

[0041] The nano-zinc oxide includes primary particles with a particle size of 20 nm or less and primary particles with a particle size of 20 nm-30 nm, wherein primary particles with a particle size of 20 nm or less account for 70%, and primary particles with a particle size of 20 nm-30 nm account for 30%. %.

[0042] The preparation method of a super wear-resistant and water-resistant airgel nano-i...

Embodiment 3

[0043] Example 3, an ultra-wear-resistant and water-resistant airgel nano-insulation material, which is made of the following raw material ratios in parts by weight: 22.5 parts of ceramic fiber felt, 14 parts of aluminum sec-butoxide, 25 parts of ethanol, deionized water 90 parts, butadiene rubber 4 parts, styrene-butadiene rubber 3 parts, catalyst 11.5 parts, activator 4 parts.

[0044] Described catalyzer is glacial acetic acid, and described active agent is made up of nano zinc oxide and stearic acid, and wherein, the weight ratio of nano zinc oxide and stearic acid is 2.5:1 part;

[0045] The nano-zinc oxide includes primary particles with a particle size of 20 nm or less and primary particles with a particle size of 20 nm-30 nm, wherein primary particles with a particle size of 20 nm or less account for 70%, and primary particles with a particle size of 20 nm-30 nm account for 30%. %.

[0046] The preparation method of a super wear-resistant and water-resistant airgel na...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com