Method for separating and detecting minodronic acid

A technology of minodronic acid and elution method is applied in the field of separation and detection of minodronic acid, which can solve the problems of low number of theoretical plates, inability to accurately evaluate the quality of minodronic acid, and less detection of the number of impurity peaks.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] 1) Instruments and conditions

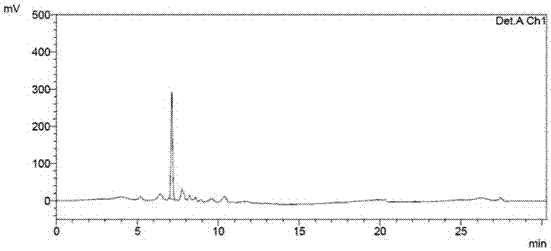

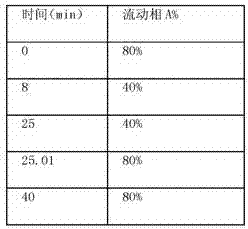

[0030] High-performance liquid chromatography: Shimadzu LC-2010AHT; filler: C18 (150mm×4.6mm, 5μm); mobile phase A: take 1.6g of sodium dihydrogen phosphate and 1.2g of sodium decanesulfonate, add 1000ml of water to dissolve, and use Adjust the pH value to 2.5 with phosphoric acid, mobile phase B: methanol; adopt linear gradient elution method; gradient elution method is as follows:

[0031]

[0032] The column temperature is 30°C; the flow rate is 1.0ml / min; the detection wavelength is 215nm; the injection volume is 10μl.

[0033] 2) Experimental steps

[0034] Take 25mg of minodronic acid fine powder, accurately weigh it, put it in the same 50ml measuring bottle, add methanol to dissolve and dilute to the mark, shake well, and use it as a mixed solution. Carry out HPLC analysis according to above-mentioned condition, record chromatogram, the result sees figure 1 . exist figure 1 Among them, the solvent peak and the excipient pea...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Column temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com