Fermented feed production process capable of increasing content of acid soluble proteins

A production process and technology of fermented feed, applied in the field of fermented feed production technology, can solve the problems of reducing anti-nutritional factors, producing acid, unable to effectively increase the content of acid-soluble protein in the feed, etc. low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

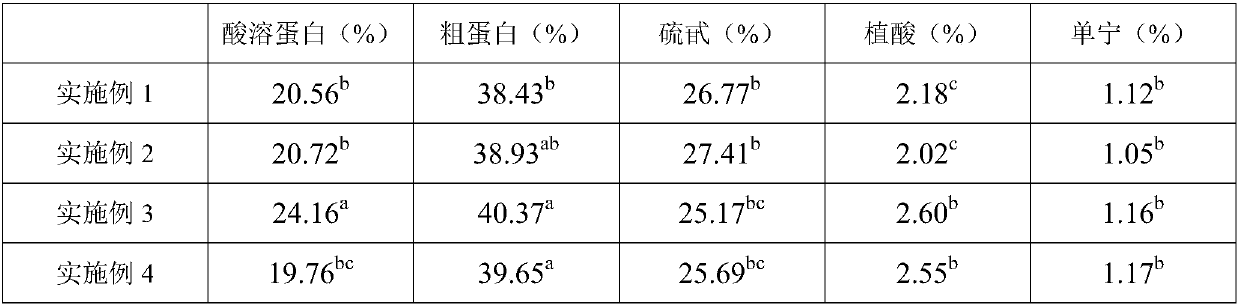

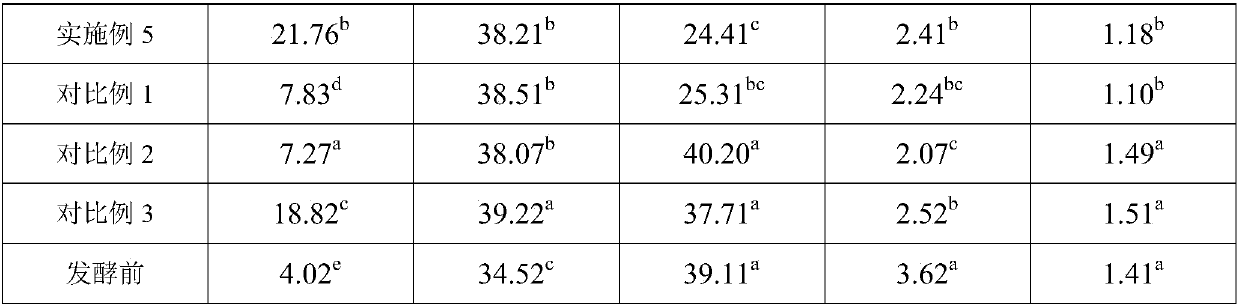

Examples

Embodiment 1

[0032] A fermented feed production process for increasing acid-soluble protein content, the specific steps are as follows:

[0033] (1) Preparation of mixed strain seed liquid: culture yeast and lactic acid bacteria separately to obtain respective strain liquids, and then mix to obtain mixed strain seed liquid;

[0034] (2) Pretreatment of concentrated feed: sterilize the concentrated feed at 90°C for 10 minutes, and then adjust its moisture content between 45% and 55%;

[0035] (3) Mixed fermentation: Mix the seed solution of mixed strains obtained in step (1) with the pretreated concentrate feed of step (2), then add neutral protease with enzyme activity ≥ 50000U / g, mix and ferment for 48 hours, and the fermentation temperature 32°C; the mass ratio of mixed strain seed solution, neutral protease and concentrated feed is 1:0.009:8.

[0036] (4) Drying and crushing: drying the fermented concentrate feed in step (3), cooling to room temperature, and crushing to obtain fermente...

Embodiment 2

[0041] A fermented feed production process for increasing acid-soluble protein content, the specific steps are as follows:

[0042] (1) Preparation of mixed strain seed liquid: culture yeast and lactic acid bacteria separately to obtain respective fermentation liquids, and then mix to obtain mixed strain seed liquid;

[0043] (2) Pretreatment of concentrated feed: sterilize the concentrated feed at 100°C for 20 minutes, then adjust its moisture content between 45% and 55%;

[0044] (3) Mixed fermentation: Mix the seed solution of mixed strains obtained in step (1) with the pretreated concentrate feed of step (2), then add neutral protease with enzyme activity ≥ 50000U / g, mix and ferment for 72 hours, and the fermentation temperature 37°C; the mass ratio of mixed strain seed solution, neutral protease and concentrated feed is 1:0.011:12.

[0045] (4) Drying and crushing: drying the fermented concentrate feed in step (3), cooling to room temperature, and crushing to obtain ferm...

Embodiment 3

[0050] A fermented feed production process for increasing acid-soluble protein content, the specific steps are as follows:

[0051] (1) Preparation of mixed strain seed liquid: ferment yeast and lactic acid bacteria separately to obtain respective fermentation liquids, and then mix to obtain mixed strain seed liquid;

[0052] (2) Pretreatment of concentrated feed: sterilize the concentrated feed at 95°C for 15 minutes, and then adjust its moisture content between 45% and 55%;

[0053] (3) Mixed fermentation: Mix the seed solution of mixed strains obtained in step (1) with the pretreated concentrate feed of step (2), then add neutral protease with enzyme activity ≥ 50000U / g, mix and ferment for 60 hours, and the fermentation temperature 35°C; the mass ratio of mixed strain seed solution, neutral protease and concentrated feed is 1:0.01:10.

[0054] (4) Drying and crushing: drying the fermented concentrate feed in step (3), cooling to room temperature, and crushing to obtain fe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com