Camellia cleansing oil having refreshing texture and preparation method of camellia cleansing oil

The technology of cleansing oil and camellia oil is applied in the directions of cosmetic preparations, cosmetic preparations, preparations for skin care, etc., and can solve the problems of obvious oily skin, difficult to dissolve makeup, poor sensibility, etc., and achieves good makeup removal effect. The effect of preventing pigmentation and shrinking pores

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] The high-permeability small molecule camellia oil of embodiment 1 is made by the following process steps:

[0049] Step 1. Preparation of crude product of high-permeability small-molecule camellia oil

[0050] Take by weight 7500g of camellia oil, 2000g of food-grade ethanol, and 20g of sodium hydroxide; heat the camellia oil to 60°C; add sodium hydroxide to the food-grade ethanol to fully dissolve it, and make an alcohol-alkali solution; Slowly add alcohol-alkali solution to camellia oil, heat to 70°C, stir at constant temperature and low speed for 0.5 hours; heat to 80°C, stir at constant temperature and high speed for 2 hours; quickly cool to room temperature, let stand for 4 hours, take the supernatant oil; The liquid was quickly cooled to -5°C (the temperature at which the supernatant oil was left to stand after cooling), and then left to stand for 3 hours (the time at which the supernatant oil was left to stand after cooling), and quickly vacuum-filtered to obtain...

Embodiment 2-6

[0054] The high-permeability small-molecule camellia oil of Examples 2-6 has substantially the same preparation process conditions as Example 1, except that the reaction raw materials and proportions of ingredients, temperature, time and other conditions are slightly different, as listed in Table 1.

Embodiment 7

[0056] Separate and collect the obtained heavy phase waste liquid in the short-range molecular distillation device in Examples 1-6, each take 1300g, a total of 7800g, replace camellia oil as the reaction raw material, add food-grade ethanol 1000g, and other preparation process steps are basically the same as in the embodiment 1. Only the proportion of ingredients, temperature, time and other conditions are slightly different, as listed in Table 1.

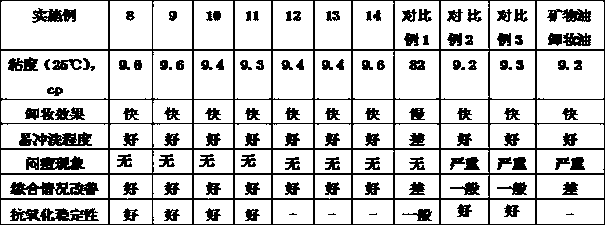

[0057] Table 1 Process conditions for the preparation of high-permeability small-molecule camellia oil in Examples 1-7

[0058]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com