Smoke denitration, desulphurization and dust removal process

A technology of desulfurization and dust removal and process method, which is applied in the field of flue gas denitrification, desulfurization and dust removal technology, can solve problems such as corrosion, corrosion equipment, GGH blockage, etc., achieve the effects of eliminating white mist in exhaust smoke, improving efficiency, and avoiding scaling and blockage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

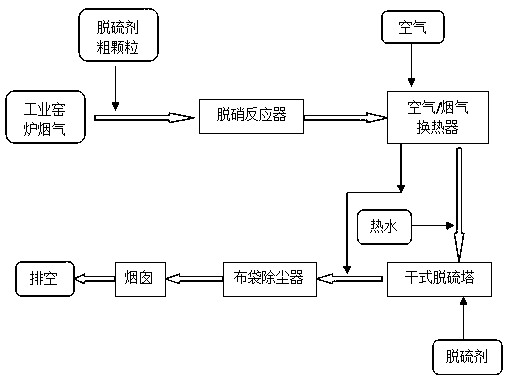

[0030] Such as figure 1 As shown, the flue gas from the industrial kiln is introduced into the coarse particle desulfurizer before entering the denitrification reactor, and the NOx in the flue gas reacts with ammonia under the action of the catalyst in the denitrification reactor to form nitrogen and water. The flue gas after denitrification enters the air / flue gas heat exchanger to cool down, then goes through hot water (water bath or spraying superheated water) to adjust the humidity, and then enters the dry desulfurization tower. The desulfurizer is supplied into the desulfurization tower in the form of dry powder, and the SO in the flue gas 2 The reaction produces dry powdered desulfurization ash. The flue gas containing desulfurization ash and dust exported from the dry desulfurization tower is mixed with the hot air from the air / flue gas and then enters the bag filter for dust removal. The clean flue gas after dust removal is emptied through the chimney.

Embodiment 2

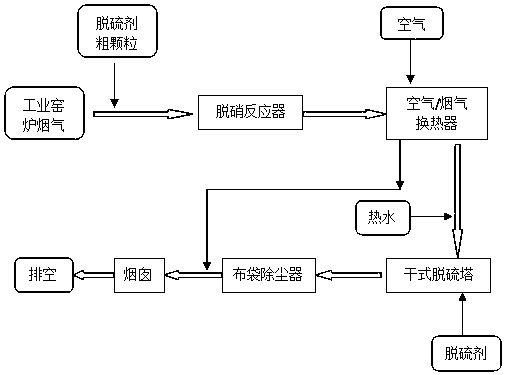

[0032] Such as figure 2 As shown, the flue gas from the industrial kiln is introduced into the coarse particle desulfurizer before entering the denitrification reactor, and the NOx in the flue gas reacts with ammonia under the action of the catalyst in the denitrification reactor to form nitrogen and water. The flue gas after denitrification enters the air / flue gas heat exchanger to cool down, then goes through hot water (water bath or spraying superheated water) to adjust the humidity, and then enters the dry desulfurization tower. The desulfurizer is supplied into the desulfurization tower in the form of dry powder, and the SO in the flue gas 2 The reaction produces dry powdered desulfurization ash. The flue gas containing desulfurization dust from the dry desulfurization tower enters the bag filter for dust removal. The clean flue gas after dust removal is mixed with the hot air from the air / flue gas and then emptied through the chimney.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com