Active carbon-dynamic membrane two-stage compound sewage direct filtering technology

A dynamic membrane and activated carbon technology, applied in adsorption water/sewage treatment, water/sludge/sewage treatment, permeation/dialysis water/sewage treatment, etc., can solve the problems of membrane fouling, operation and maintenance, high cost and frequent membrane modules. , to achieve the effect of easy anaerobic resource treatment, easy assembly and disassembly, and low filtration resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

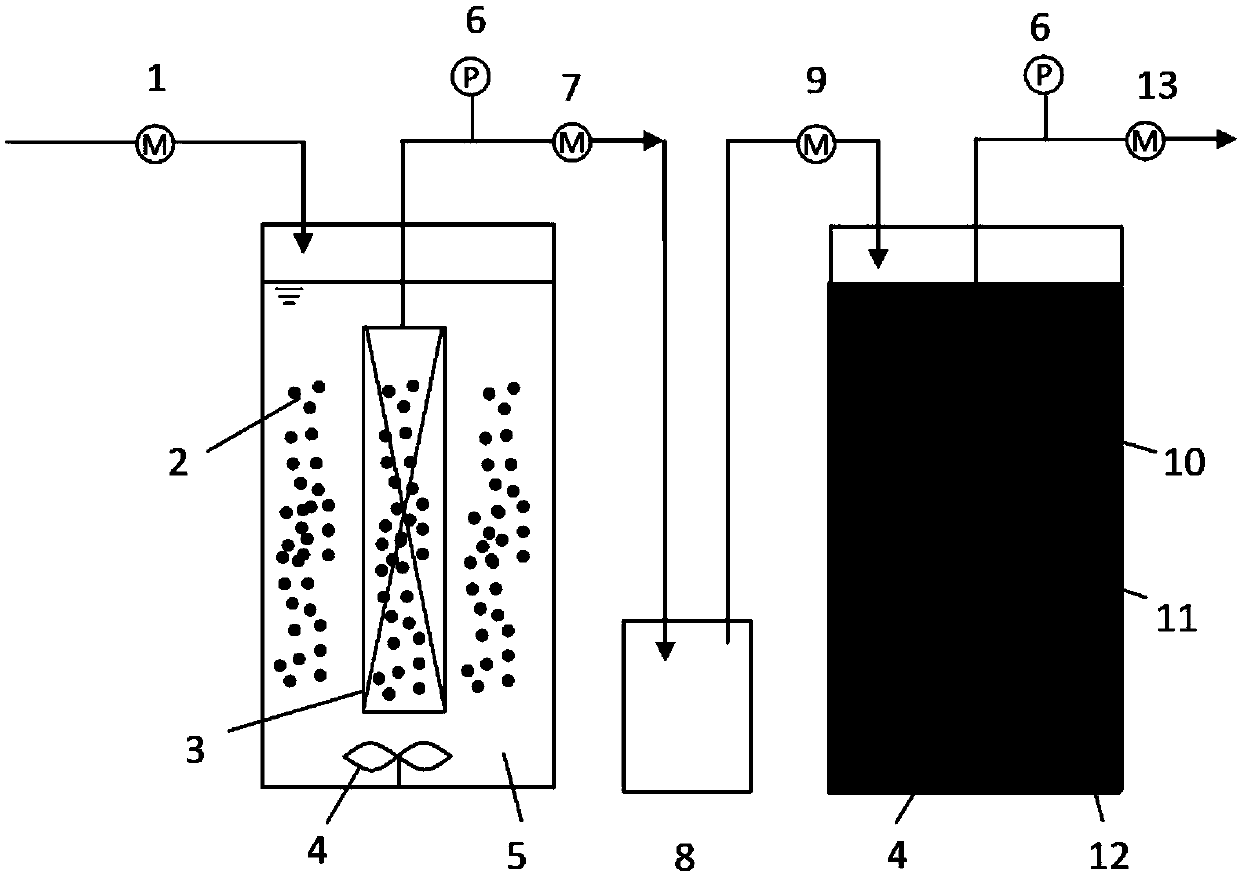

[0029] The implementation of the present invention will be described in detail below in conjunction with the drawings and examples.

[0030] The present invention is an activated carbon-dynamic membrane two-stage composite sewage direct filtration process,

[0031] In the primary reactor 5, 1 to 3 g / L of large particle size powdered activated carbon 2 (particle size is 100 to 500 μm) is added at one time, and urban sewage enters the primary reactor 5 and is stirred and mixed with the large particle size powdered activated carbon 2. After homogenization, it is filtered and separated by the macroporous membrane substrate with a pore size of 70-150 μm in the first-stage dynamic membrane module 3, and the pumped water is collected into the first-stage water production tank 8, and the interception and concentration of organic matter is realized in the first-stage reactor 5. Generate stable effluent and weaken the impact of raw water quality fluctuations on the secondary reactor 12....

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com