Single-layer durable building heat insulation Low-E glass and preparation method thereof

A technology for building thermal insulation and durability, applied in glass manufacturing equipment, glass tempering, manufacturing tools, etc., can solve the problems of easy damage to the coating, easy entry of sunlight and heat into the room, etc., to reduce production costs and prevent mechanical damage. Good effect of external erosion, thermal insulation performance and thermal insulation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

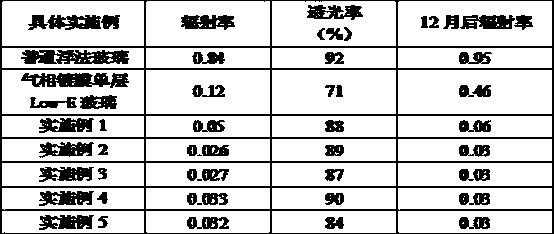

Examples

Embodiment 1

[0031] (1) In a nitrogen atmosphere, add 100kg of glass, 5kg of fluxing agent calcium carbonate, and 0.3kg of clarifying agent sodium sulfate into the furnace, heat at a high temperature to 1300~1400°C to melt the glass, then add 15kg of silver powder, and place in a constant temperature stirrer 1400~1500℃, the stirring speed is 50r / min; stir for 5-10min to obtain the coating solution;

[0032] (2) Use a fully automatic glass cutting machine to cut the glass plate according to the size, and then use an edger to grind the edge; then use the horizontal convection heating method to strengthen the preheating treatment on the glass plate; and then use the step (1) The coating liquid is evenly applied to the surface of the glass plate under the condition of pressure of 2MPa through the compressed nitrogen gas flow to form a functional film that acts as a barrier and protection;

[0033] (3) Place the glass plate coated in step (2) in a tempering furnace, the tempering furnace is a f...

Embodiment 2

[0036] (1) In a nitrogen atmosphere, add 100kg of glass, 6kg of flux calcium carbonate, and 0.5kg of clarifying agent antimony oxide into the furnace, heat at high temperature to 1300~1400°C to melt the glass, then add 15kg of silver powder, and place in a constant temperature stirrer 1400~1500℃, the stirring speed is 80r / min; stir for 10min to get the coating solution;

[0037](2) Use a fully automatic glass cutting machine to cut the glass plate according to the size, and then use an edger to grind the edge; then use the horizontal convection heating method to strengthen the preheating treatment on the glass plate; and then use the step (1) The coating liquid is evenly applied to the surface of the glass plate under the condition of a pressure of 2.5MPa through a compressed nitrogen gas flow to form a functional film that acts as a barrier and protection;

[0038] (3) Place the glass plate coated in step (2) in a tempering furnace, the tempering furnace is a forced convectio...

Embodiment 3

[0041] (1) In a nitrogen atmosphere, add 100kg of glass, 8kg of flux lithium borate, and 0.4kg of clarifying agent sodium chloride into the furnace, heat at a high temperature to 1300~1400°C to melt the glass, then add 18kg of silver powder, and place in a constant temperature stirrer 1400~1500℃, the stirring speed is 100r / min; stir for 10min to obtain the coating solution;

[0042] (2) Use a fully automatic glass cutting machine to cut the glass plate according to the size, and then use an edger to grind the edge; then use the horizontal convection heating method to strengthen the preheating treatment on the glass plate; and then use the step (1) The coating liquid is evenly applied to the surface of the glass plate under the condition of pressure 3.0MPa through the compressed nitrogen gas flow to form a functional film that acts as a barrier and protection;

[0043] (3) Place the glass plate coated in step (2) in a tempering furnace, the tempering furnace is a forced convect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com