A binder for perlite thermal insulation products and its preparation method

A technology of binder and perlite, which is applied in the field of binder and preparation of perlite thermal insulation products, can solve the problems of high water absorption, high production cost, low compressive strength, etc., and achieve fast curing time and uniform distribution , good temperature resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

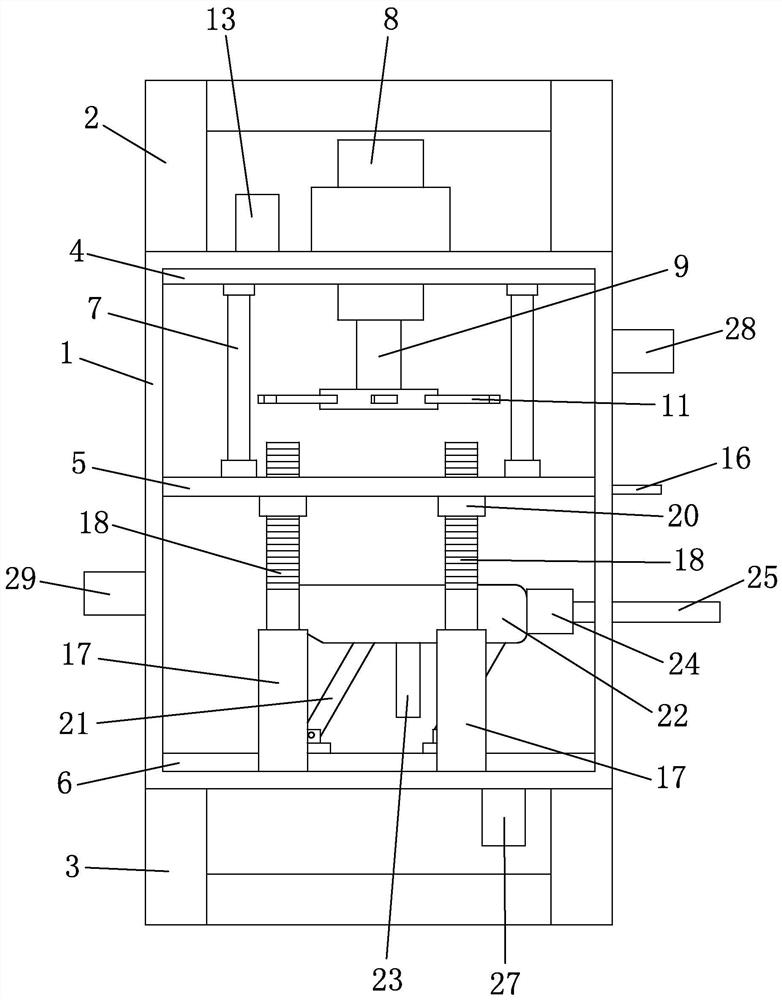

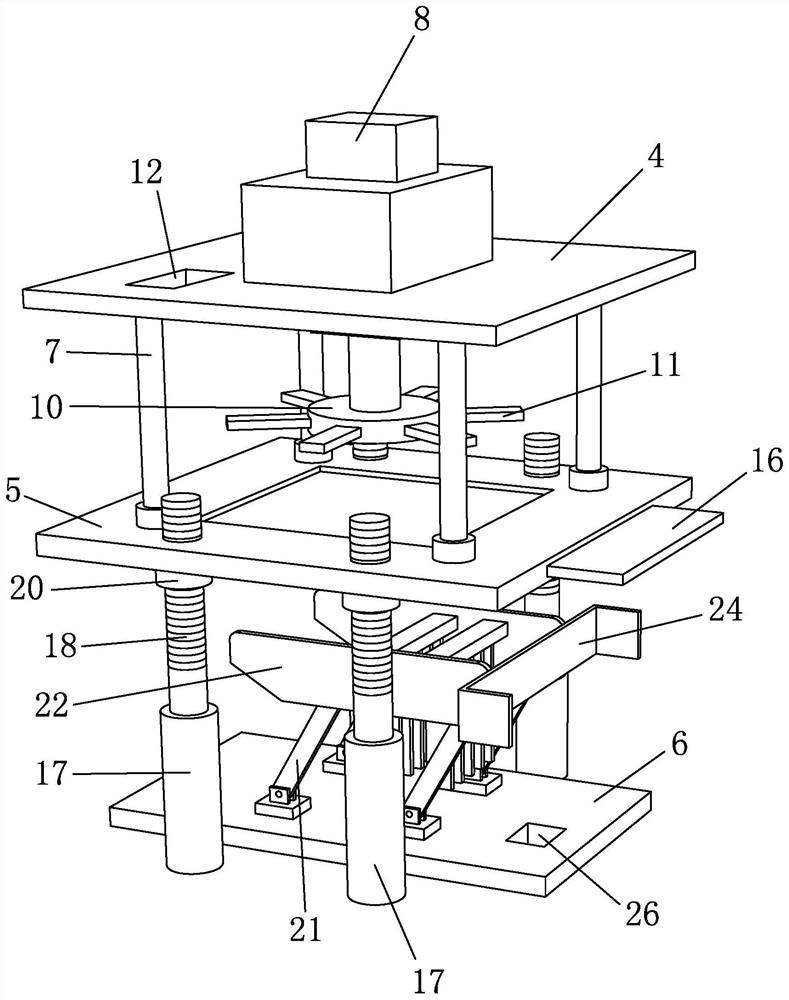

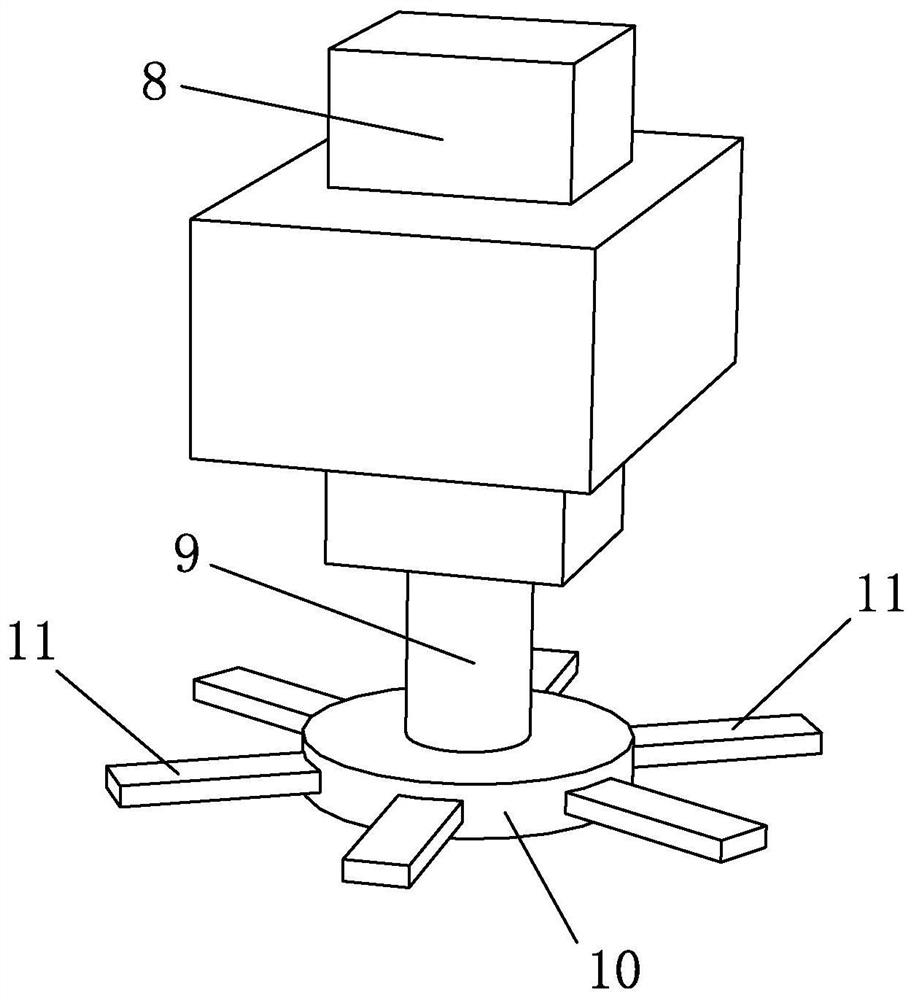

[0028] Such as Figure 1 to Figure 6 As shown, it is a binder used for perlite insulation products in the present invention. The raw materials of the binder include Shuangfei powder, white cement, calcium silicate powder, thickener, redispersed latex powder, and pregelatinized tapioca starch and water, the parts by weight of each component are:

[0029]

[0030]A method for preparing a binder for perlite thermal insulation products, which uses the above-mentioned raw materials and a two-way preparation device for preparation. The two-way preparation device includes a preparation housing 1 , a first placement base 2 and a second placement base 3 , and the first placement base 2 and the second placement base 3 are fixed at both ends of the preparation housing 1 . The first connecting plate 4 , the second connecting plate 5 and the third connecting plate 6 are provided in the preparation shell 1 in order from top to bottom, and the supporting rod 7 is between the first connec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com