Stabilization promoter for rust layer of weather-resisting steel and application method

A stabilization accelerator and weather-resistant steel technology, applied in coatings, anti-corrosion coatings, etc., can solve problems such as inapplicability, achieve the effects of reducing costs, speeding up stabilization, and improving corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Wherein the main agent is 35% by mass of polyvinyl butyral resin; Accelerator A is 5% by mass of ferric oxide; Modifier is 7.9% by mass of chromium sulfate; Rust inhibitor is 2.8% by mass Sodium molybdate; Complexing agent is the mixture of 1.2% mass parts tannins and lactic acid, the mass ratio of tannins and lactic acid is 1:0.1; Adjuvant is 16.5% mass parts barium sulfate; Initiator is 1% The mass part is iron red, and the balance is water.

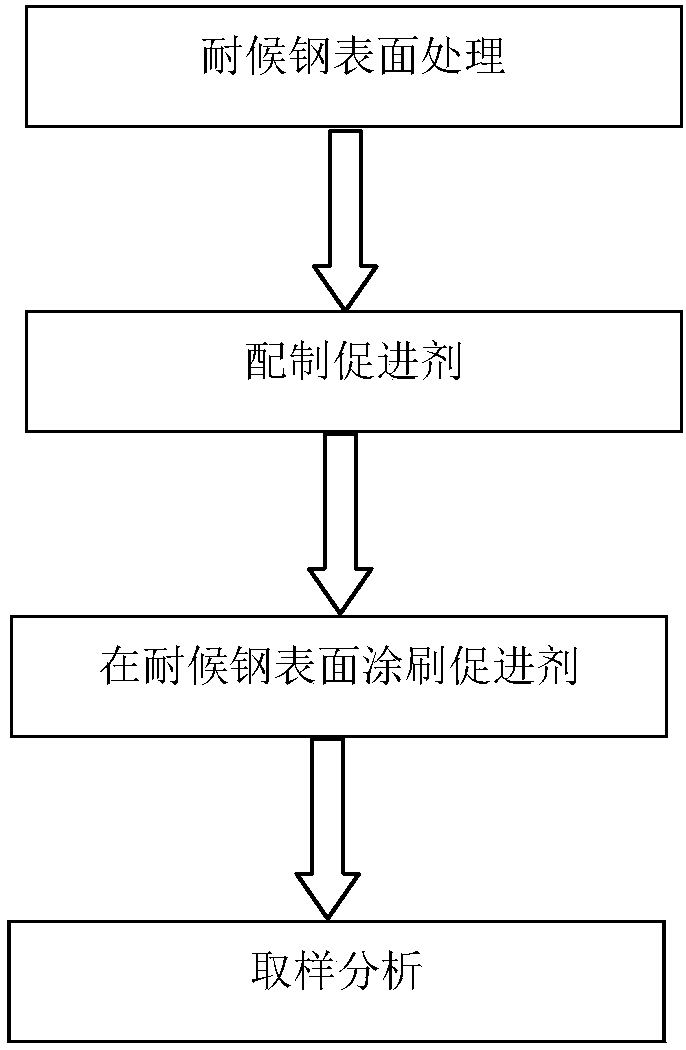

[0032] The method for using the weathering steel rust layer stabilization accelerator includes the following steps:

[0033] Step 1: Select a finished sample of weathering steel of a certain size. After degreasing with acetone, clean it with absolute ethanol and dry it for later use. Shot peen the surface of the weathering steel to be treated, using shot materials such as glass beads and ceramic beads Or steel balls, etc., quickly hit the surface of the weathering steel to change the stress state of the surface, and at the same...

Embodiment 2

[0037] Wherein the main agent is 47% by mass of polyvinyl butyral resin; accelerator A is 1% by mass of ferric oxide; modifier is 8.5% by mass of chromium sulfate; rust inhibitor is 0.6% by mass Sodium molybdate; The complexing agent is a mixture of 3.8% by mass of tannin and lactic acid, and the mass ratio of tannin and lactic acid is 1:2; the auxiliary agent is 15.3% by mass (specific value) barium sulfate; the initiator is 1.5% by mass (specific value) iron red, the balance is water.

[0038] Concrete implementation steps are the same as embodiment 1

Embodiment 3

[0040] Wherein the main agent is 40% by mass of polyvinyl butyral resin; accelerator A is 3% by mass of ferric oxide; modifier is 8.2% by mass of chromium sulfate; rust inhibitor is 1.5% by mass Sodium molybdate; Complexing agent is the mixture of 2% mass parts tannins and lactic acid, the mass ratio of tannins and lactic acid is 1:1.2; Adjuvant is 15.8% mass parts barium sulfate; Initiator is 1.2% The mass part is iron red, and the balance is water.

[0041]Concrete implementation steps are the same as embodiment 1

[0042] Finally, the weekly immersion corrosion test was carried out on the sample coated with the rust stabilizer, and the weight loss corrosion rate and electrochemical analysis of the rust layer were carried out on the sample after the experiment. Through experiments, it can be concluded that after the smear is applied on the surface, the total weight of the specimen increases compared with the bare state, and the corrosion rate of the weathering steel is also...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com