Yeast polypeptide as well as preparation method and applications thereof

A yeast polypeptide and yeast protein technology, applied in the field of protein polypeptides, can solve the problems of undisclosed polypeptide purity and molecular weight distribution, and achieve the effects of improving food flavor, improving dry and split ends, and repairing damaged hair.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

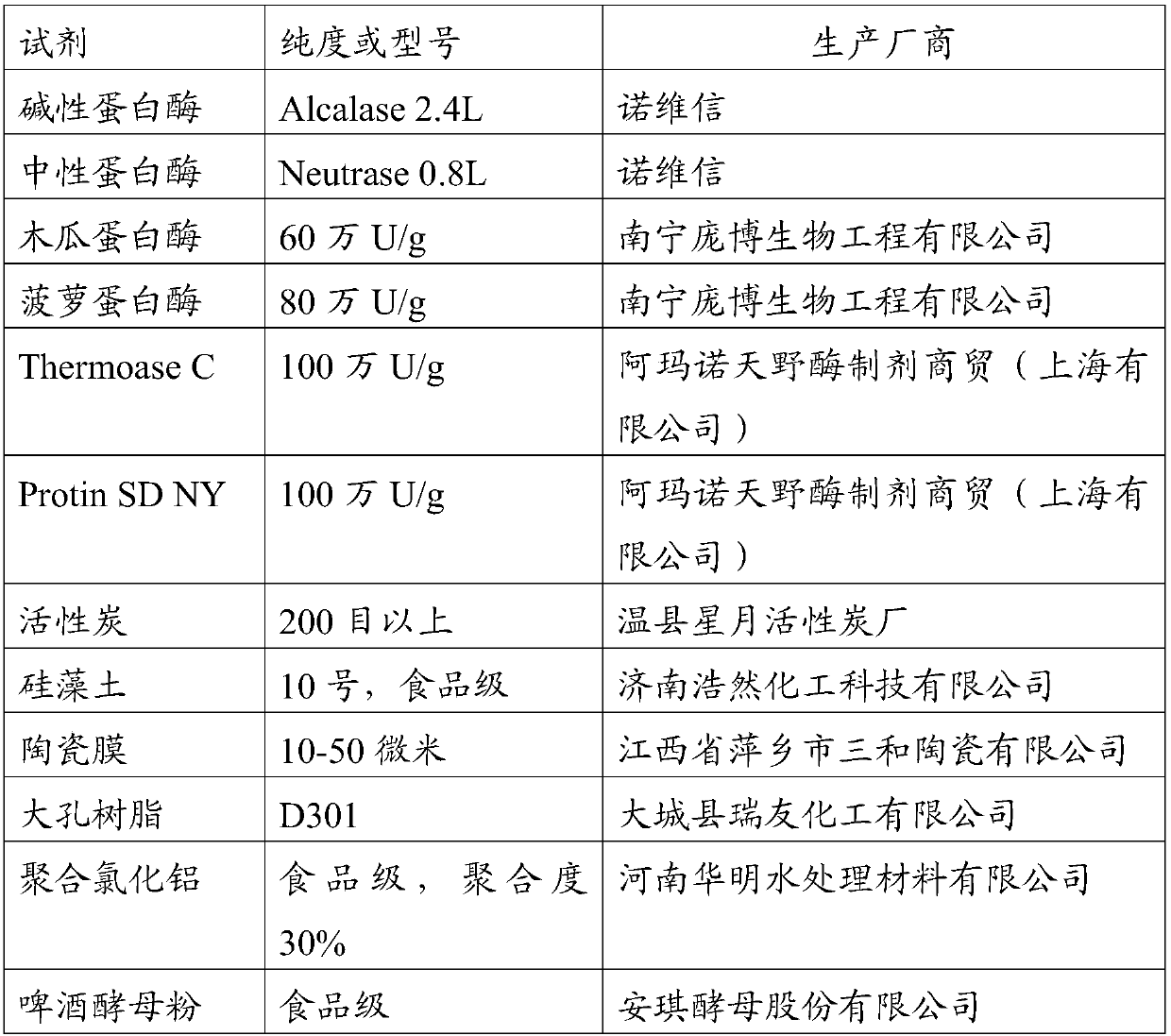

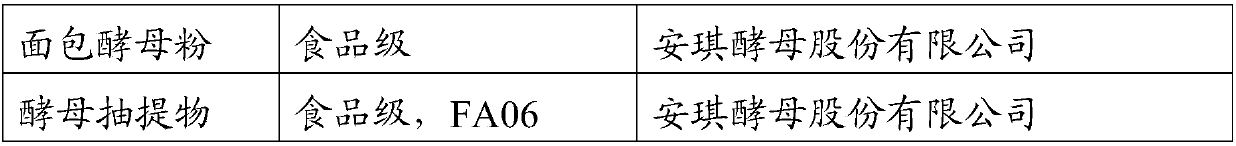

Method used

Image

Examples

preparation example Construction

[0040] Wherein, in a specific embodiment of the present invention, a method for preparing a yeast polypeptide is provided, comprising the following steps:

[0041] (1) extract the yeast protein in the raw material;

[0042] (2) adding alkaline protease for enzymolysis, then adding complex protease for enzymolysis, collecting the supernatant to obtain the enzymolysis product;

[0043] (3) Separation and decolorization to obtain yeast polypeptide.

[0044] Wherein, the action time of extracting yeast protein under alkaline condition in step (1) is 2-6h.

[0045] Wherein, the step (1) separates the yeast protein obtained under alkaline conditions and takes the supernatant, adjusts the pH value to 3.0-7.0, stands still at 10-30°C for 1-5h, and then separates to obtain a paste-like precipitate.

[0046] Wherein, the enzymolysis time of alkaline protease in step (2) is 1-5h, preferably 2-4h.

[0047] The enzymolysis time of the composite protease in step (2) is 1-20h, preferably ...

Embodiment 1

[0060] The method for preparing yeast polypeptide, the steps are as follows:

[0061] (1) Add 10kg of beer yeast powder and pure water to make a solution of 500kg, add alkali to adjust the pH to 12.5, extract at 60°C for 2 hours, centrifuge at 10,000rpm to get the supernatant, adjust the pH to 4.7 with dilute hydrochloric acid, and refrigerate to 20°C Let stand for 1h, and centrifuge at 10000rpm.

[0062] (2) Add 100kg of purified water to the centrifuged protein paste and wash it again and centrifuge again to obtain a protein paste of about 25kg. The crude protein content measured by a moisture analyzer is 12% of the paste weight, and the crude protein is the content after water removal.

[0063] (3) Dissolve the crude protein with water to a volume of 60L, heat and stir evenly, keep at 70°C for 30min, cool down to 55°C, adjust the pH to 8.0, add 15g of alkaline protease, enzymatically hydrolyze for 2h, cool down to 50°C, add medium Protease 15g, papain 30g enzymolysis 10h. ...

Embodiment 2

[0077] The method for preparing yeast polypeptide, the steps are as follows:

[0078] (1) Add 10 kg of yeast extract and purified water to prepare 50 kg of a solution, adjust the pH to 11, and set the temperature to 55° C. After 6 hours of extraction, centrifuge at 5000 rpm to obtain the supernatant. Add acid to the supernatant to adjust the pH to 4.5 to precipitate protein. After cooling to 30°C, let it stand for 5 hours and centrifuge at 5000rpm.

[0079] (2) Add 50kg of purified water to the protein paste after centrifugation, wash and centrifuge. Obtain protein cream 30.3kg, crude protein content is about 9.3% of cream weight.

[0080] (3) Crude protein was dissolved in water to 60kg, heated to 80°C and kept for 25 minutes, cooled to about 55°C, added alkali to adjust pH to 7.8, added 3g of alkaline protease for 3 hours, and then added 35g of papain for 16 hours.

[0081] Adjust the pH of the solution to 4.7, then heat to 75°C for 20 min, and centrifuge to take the supe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com