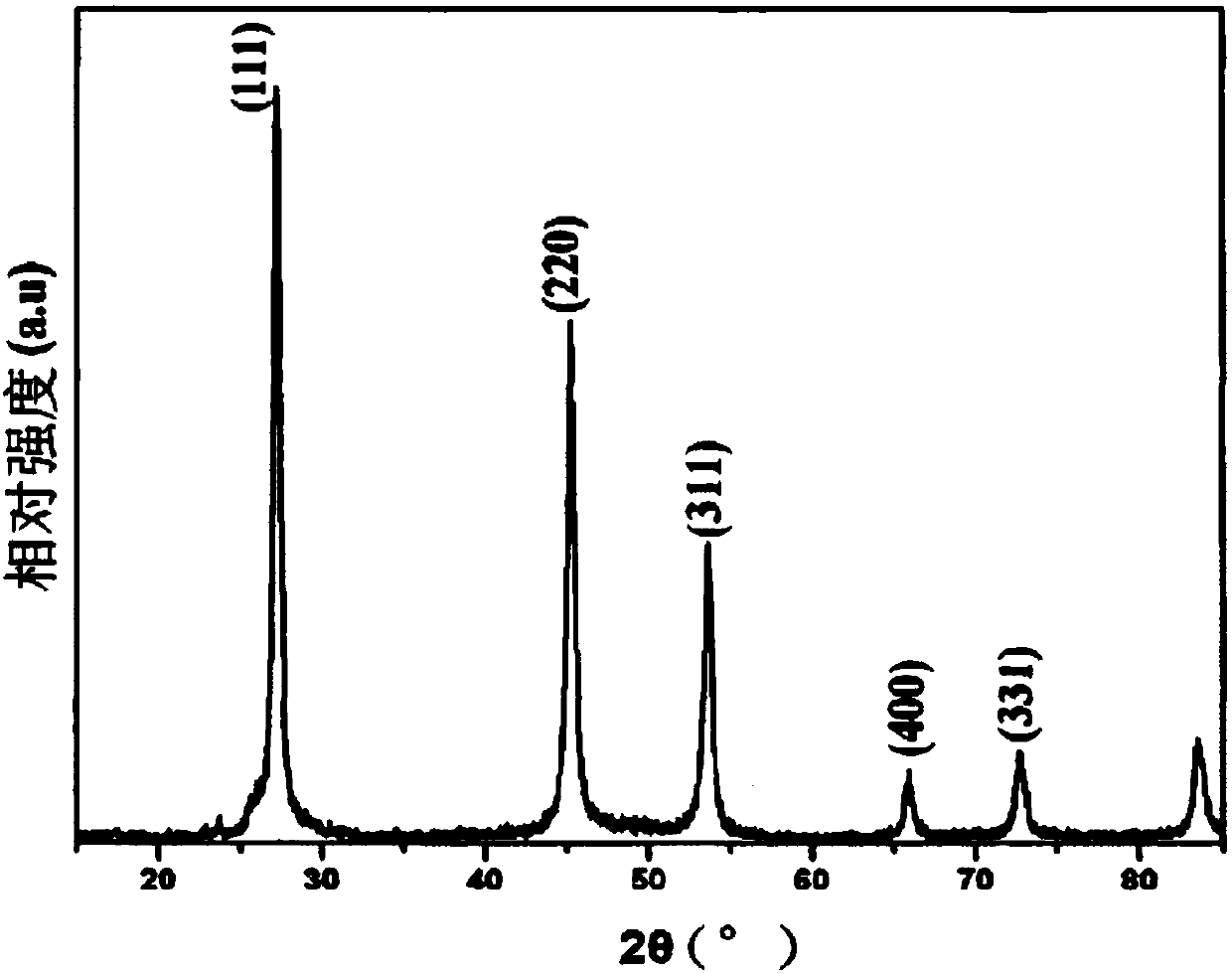

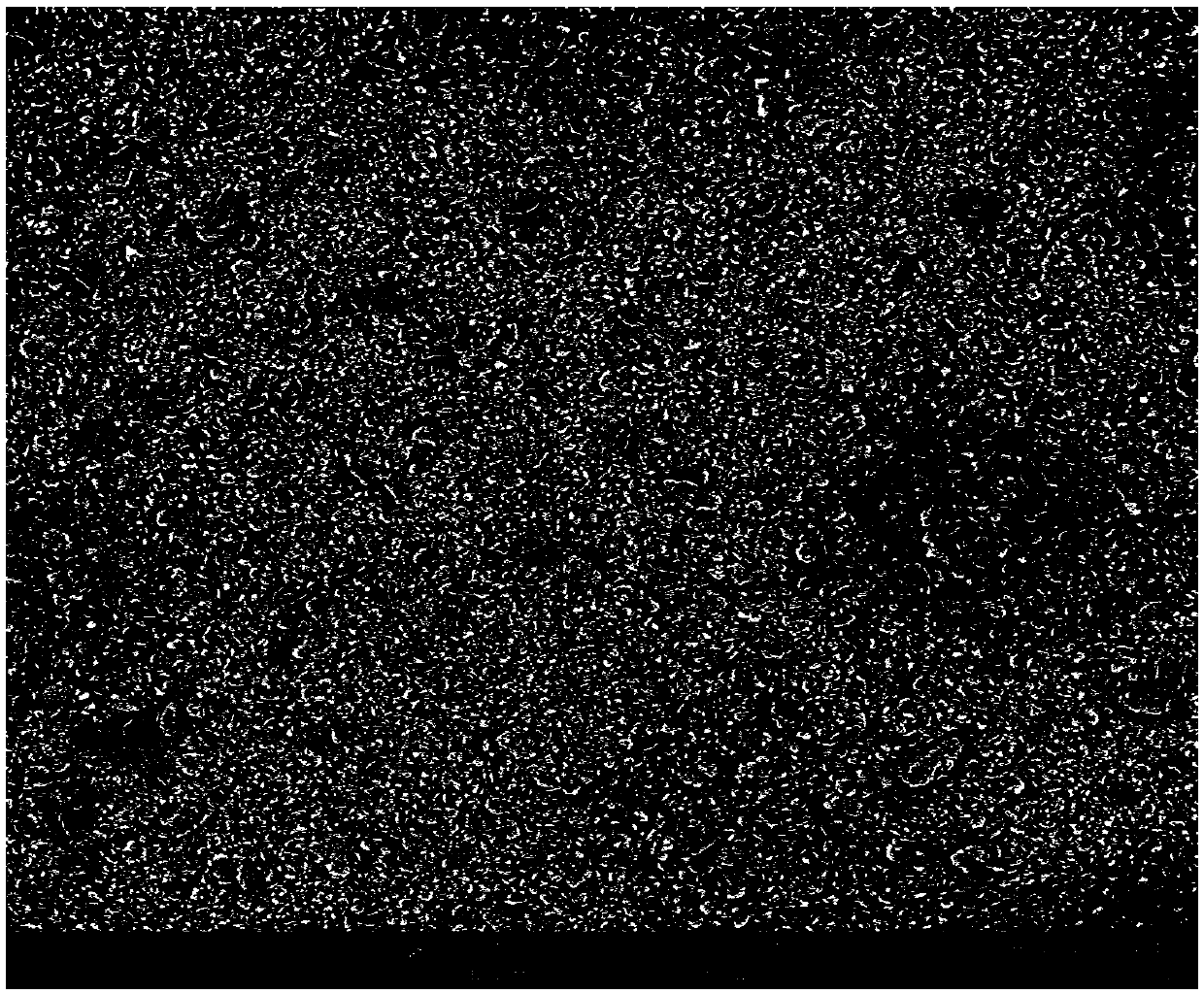

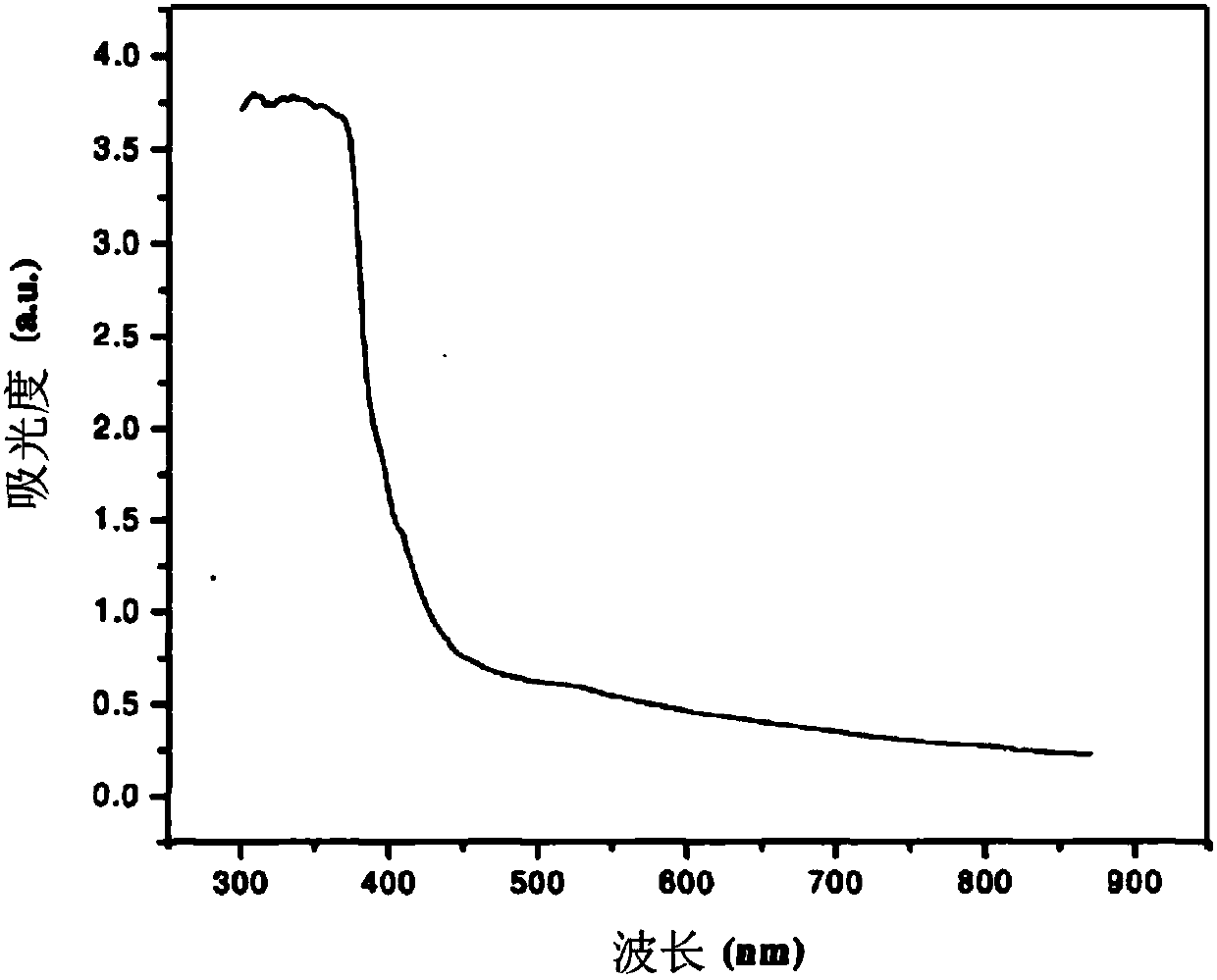

Preparation method of zinc selenide membrane

A zinc selenide and thin film technology, applied in electrolytic inorganic material coating and other directions, can solve the problems of difficult control of product uniformity, high production cost, difficult to enlarge, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] A kind of preparation method of zinc selenide thin film of the present invention specifically comprises the following steps:

[0025] (1) Clean the fluorine-doped tin dioxide conductive glass (FTO, used as the cathode sheet) three times with detergent, soak it in isopropanol ultrasonically for 15 minutes, then soak it in ethanol ultrasonically for 15 minutes, rinse it three times with deionized water, and then Drying with nitrogen gas to obtain fluorine-doped tin dioxide conductive glass with a clean surface;

[0026] (2) Configure a mixed solution containing 2mol / L sodium hydroxide, 10mmol / L selenous acid, 10mmol / L zinc acetate, and 0.5mol / L disodium edetate, and then use nitrogen gas bubbling to remove the mixed solution. Oxygen 15min;

[0027] (3) With step (2) gained mixed solution as electrochemical deposition liquid, with step (1) gained clean fluorine-doped tin dioxide conductive glass as counter electrode, with saturated calomel electrode as reference electrode...

Embodiment 2

[0031] A kind of preparation method of zinc selenide thin film of the present invention specifically comprises the following steps:

[0032] (1) Clean the fluorine-doped tin dioxide conductive glass (FTO, used as the cathode sheet) three times with detergent, soak it in isopropanol ultrasonically for 15 minutes, then soak it in ethanol ultrasonically for 15 minutes, rinse it three times with deionized water, and then Drying with nitrogen gas to obtain fluorine-doped tin dioxide conductive glass with a clean surface;

[0033] (2) Configure a mixed solution containing 2mol / L sodium hydroxide, 10mmol / L selenous acid, 10mmol / L zinc acetate, and 0.5mol / L disodium edetate, and then use nitrogen gas bubbling to remove the mixed solution. Oxygen 15min;

[0034] (3) With step (2) gained mixed solution as electrochemical deposition liquid, with step (1) gained clean fluorine-doped tin dioxide conductive glass as counter electrode, with saturated calomel electrode as reference electrode...

Embodiment 3

[0038] A kind of preparation method of zinc selenide thin film of the present invention specifically comprises the following steps:

[0039] (1) Clean the fluorine-doped tin dioxide conductive glass (FTO, used as the cathode sheet) three times with detergent, soak it in isopropanol ultrasonically for 15 minutes, then soak it in ethanol ultrasonically for 15 minutes, rinse it three times with deionized water, and then Drying with nitrogen gas to obtain fluorine-doped tin dioxide conductive glass with a clean surface;

[0040] (2) Configure a mixed solution containing 2mol / L sodium hydroxide, 10mmol / L selenous acid, 10mmol / L zinc acetate, and 0.5mol / L disodium edetate, and then use nitrogen gas bubbling to remove the mixed solution. Oxygen 15min;

[0041] (3) With step (2) gained mixed solution as electrochemical deposition liquid, with step (1) gained clean fluorine-doped tin dioxide conductive glass as counter electrode, with saturated calomel electrode as reference electrode...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com