Antibacterial additive and preparation method thereof

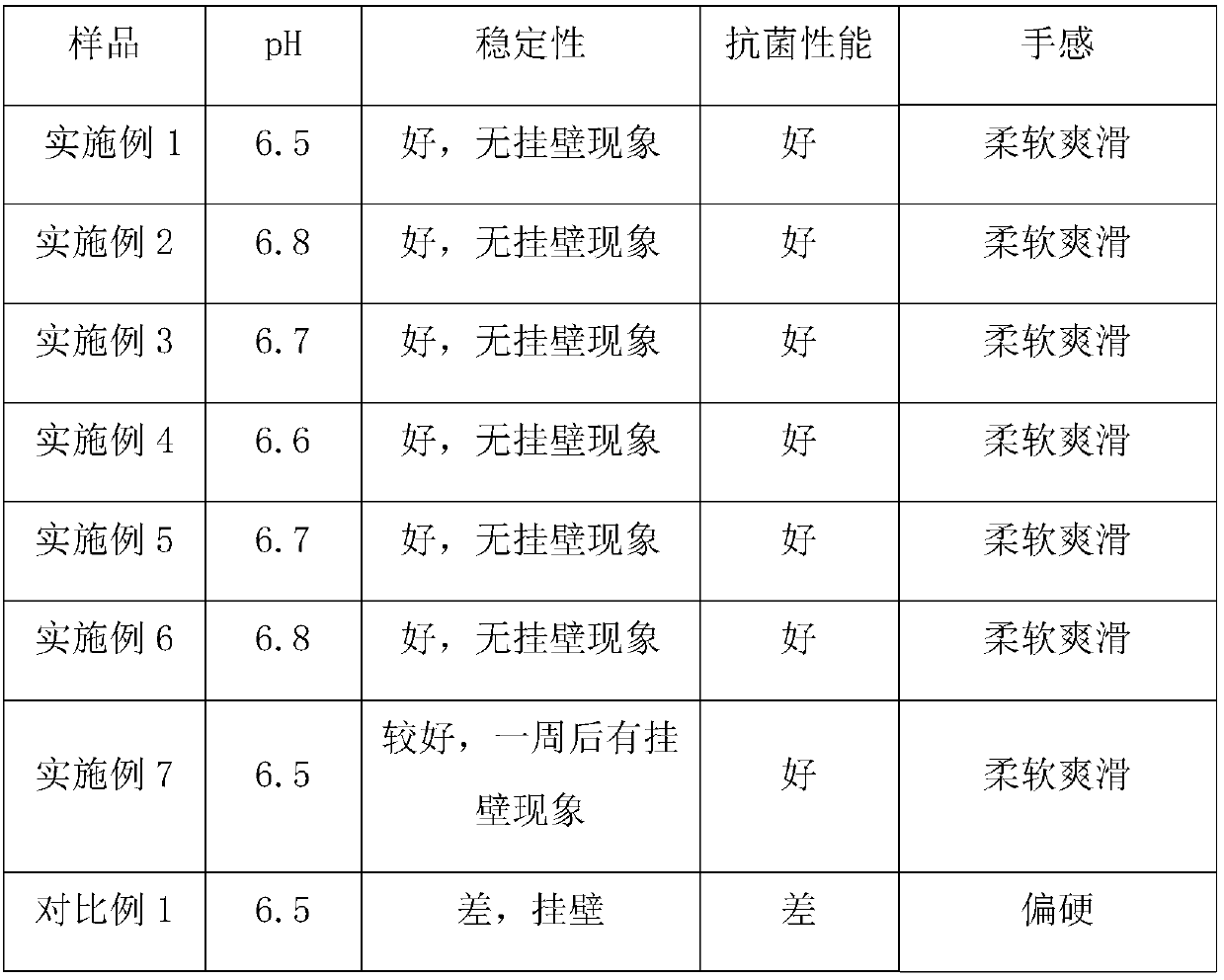

A technology of antibacterial auxiliary agent and emulsifier is applied in the field of antibacterial auxiliary agent and its preparation to achieve the effect of improving antibacterial performance and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0050] The present invention also provides a kind of preparation method of antibacterial auxiliary agent, described antibacterial auxiliary agent is above-mentioned antibacterial auxiliary agent, and described preparation method comprises:

[0051] The ternary copolymerized polydimethylsiloxane, bis-(tallow amidohexyl)-polyethoxymethylammonia-methylsulfate, hydroxyl modified polydimethylsiloxane, emulsifier, organic acid , water and solubilizer are mixed and stirred evenly.

[0052] Further, first ternary copolymerized polydimethylsiloxane, bis-(tallow amidohexyl)-polyethoxymethylammonia-methylsulfate, hydroxyl modified polydimethylsiloxane and emulsified The agent is mixed and stirred evenly at 25-80°C, such as 25°C, 30°C, 35°C, 40°C, 45°C, 50°C, 60°C, 70°C or 80°C, and then add organic acid, water and solubilizer in sequence Mix and stir well.

[0053] Preferably, the mixing and stirring temperature is 25-40°C, more preferably, the mixing and stirring temperature is 35-40°...

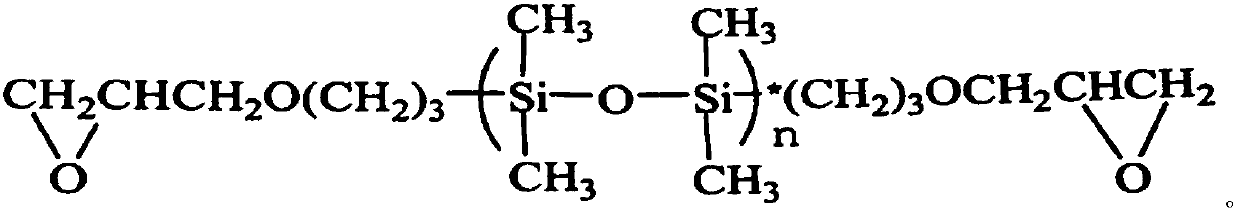

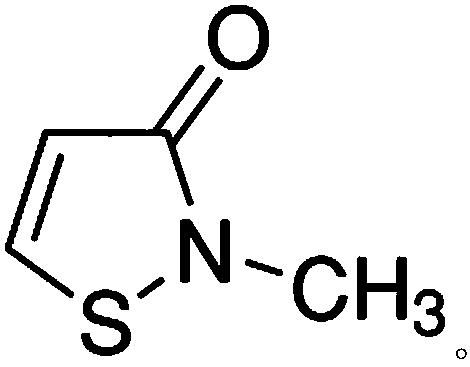

Embodiment 1

[0057] (1) Preparation of ternary copolymerized polydimethylsiloxane: Take 40 parts of epoxy-terminated silicone oil with a molecular weight of 3000, 5 parts of N, N-dimethylcyclohexylamine and 30 parts of isopropanol to reflux at 80°C After reacting for 8 hours, the solvent was removed under reduced pressure to obtain ternary copolymerized polydimethylsiloxane.

[0058] (2) First take 30 parts of ternary copolymerized polydimethylsiloxane, 25 parts of bis-(tallow amidohexyl)-polyethoxymethylammonia-methylsulfate, 5 parts of hydroxyl modified polydimethylsiloxane Siloxane and 4 parts of isomeric tridecyl alcohol polyoxyethylene ether-7-ethylene oxide were mixed and stirred evenly at 25 ° C, then 0.5 parts of glacial acetic acid was added, and 50 parts of water were slowly added, and finally 5 parts of glycerol were added Alcohol is mixed and stirred evenly to obtain the antibacterial auxiliary agent.

[0059] The above-mentioned hydroxyl-modified polydimethylsiloxane is a hyd...

Embodiment 2

[0061] (1) Preparation of ternary copolymerized polydimethylsiloxane: take 50 parts of 8000 molecular weight terminal epoxy silicone oil, 8 parts of N, N-dimethylcyclohexylamine and 40 parts of isopropanol and reflux at 83 °C After reacting for 7.5 hours, the solvent was removed under reduced pressure to obtain ternary copolymerized polydimethylsiloxane.

[0062] (2) First take 35 parts of ternary copolymerized polydimethylsiloxane, 23 parts of bis-(tallow amidohexyl)-polyethoxymethylammonia-methylsulfate, 6 parts of hydroxyl modified polydimethylsiloxane Siloxane and 6 parts of isomeric tridecyl alcohol polyoxyethylene ether-7-ethylene oxide were mixed and stirred evenly at 40 ° C, then 0.8 parts of glacial acetic acid was added, and 60 parts of water were slowly added, and finally 8 parts of glycerol were added Alcohol is mixed and stirred evenly to obtain the antibacterial auxiliary agent.

[0063] The above-mentioned hydroxyl-modified polydimethylsiloxane is a hydroxyl-mo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com