Method for preparing monoester type aconite total alkaloid and application thereof

A technology of total alkaloids and aconitum, applied in the field of natural medicinal chemistry research, can solve the problems of reduced pharmacological activity, reduced toxicity, and irregularities

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

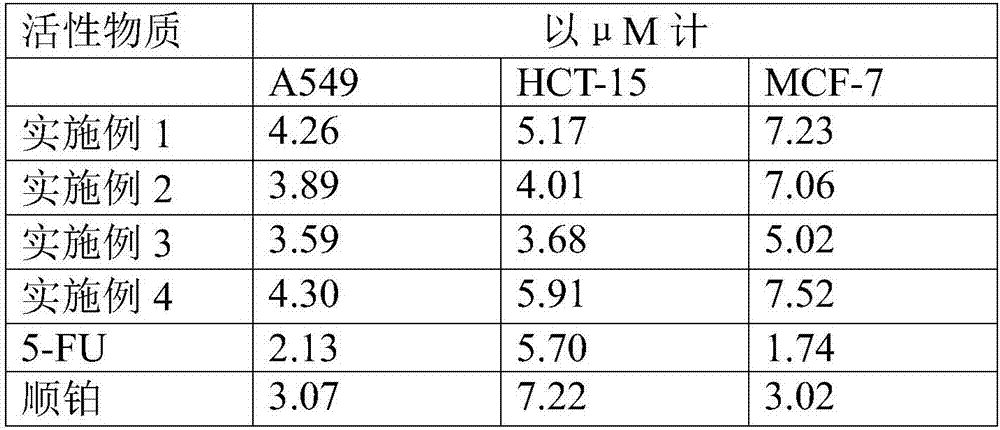

Examples

Embodiment 1

[0009] Take 1 kg of dried Aconitum aconitum powder, put it into a percolation device, extract it by percolation with 10L ethyl acetate (ammonia water 2%) for 32 hours, and recover the ethyl acetate under reduced pressure from the percolation solution to obtain 200ml of concentrated solution, acidify with 0.5% HCl to pH = 2, extracted three times with ethyl acetate, alkalized the aqueous layer with 0.5% NaOH to pH = 12, extracted three times with ethyl acetate, combined the ethyl acetate layers, and concentrated to obtain 6 g of total aconitum alkaloids. Add the total alkaloids of Aconitum to 40% by volume of 1,4-dioxane, heat and reflux for 5 hours, concentrate the hydrolyzate and acidify it to pH=2 with 0.5% HCl, extract with ethyl acetate, water The layer was basified with 0.5% NaOH to pH = 12, extracted with ethyl acetate, the ethyl acetate layers were combined, and the ethyl acetate was recovered under reduced pressure to obtain 3.7 g of total monoester aconitum alkaloids w...

Embodiment 2

[0011] Take 1kg of dried Aconitum aconitum powder, impregnate it with methanol (2.5% ammonia water), put it into a percolation device, use 12L methanol (2.5% ammonia water) for percolation extraction for 32 hours, recover methanol under reduced pressure from the percolation liquid, and obtain 300ml concentrated liquid. Acidify with 1.0% sulfuric acid to pH = 1, extract 3 times with petroleum ether, alkalinize the aqueous layer with 0.8% KOH to pH = 12, extract 3 times with petroleum ether, combine the petroleum ether layers, concentrate to obtain the total organism of Aconitum aconitum Alkali 7g. Add the total alkaloids of Aconitum 50% by volume to 1,4-dioxane, heat and reflux for 5 hours, concentrate the hydrolyzate and acidify it to pH=2 with 0.5% sulfuric acid, extract with petroleum ether, and the water layer Then use 0.5% KOH to alkalinize to pH = 12, extract with petroleum ether, combine petroleum ether, and recover petroleum ether under reduced pressure to obtain 4.5 g...

Embodiment 3

[0013] Take 8kg of dried Aconitum aconitum powder, impregnate the Aconitum aconitum powder with ethanol (containing 2.5% ethylenediamine), put it into a percolation device, extract by percolation with 75L ethanol (containing 2.5% ethylenediamine) for 32 hours, and depressurize the percolation liquid Recover ethanol to obtain 960ml concentrated solution, acidify with 0.5% nitric acid to pH = 1, extract 3 times with cyclohexane, alkalinize the aqueous layer with 0.5% calcium hydroxide to pH = 12, extract 3 times with cyclohexane, and combine The cyclohexane layer was concentrated to obtain 51 g of total aconitum alkaloids. Add the total alkaloids of Aconitum 60% by volume to 1,4-dioxane, heat and reflux for 7 hours, concentrate the hydrolyzate, acidify it with 0.5% nitric acid to pH=1-2, and extract it with cyclohexane , the aqueous layer was basified with 0.5% calcium hydroxide to pH = 11-12, extracted with cyclohexane, the cyclohexane layers were combined, and the cyclohexane ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com