Preparation method of water treatment purifying agent

A purifying agent and water treatment technology, applied in the field of environmental science, can solve the problems of poor thermal stability, increased cost, and large dosage of water treatment chemicals, and achieve low production cost, low use cost, excellent corrosion and scale inhibition performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

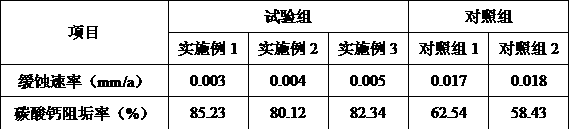

Examples

Embodiment 1

[0013] The preparation method of water treatment purifying agent comprises the synthesis of polyether monomer, the synthesis of scale inhibitor, and the preparation of water treatment purifying agent. The specific steps are:

[0014] 1) Synthesis of polyether monomer: put maleic anhydride and allyl polyoxyethylene ether with a molar ratio of 1:11 into a reaction vessel, mechanically stir at room temperature for 55 minutes, and then uniformly heat to 65°C to stir the reaction After 3.5 hours, cool to room temperature to obtain the polyether monomer, which is ready for use. The terminal hydroxyl group of the allyl polyoxyethylene ether molecule is a chemically active group, and the stability and water solubility of the terminal hydroxyl group are worse than those of the carboxyl group. Therefore, allyl polyoxyethylene ether can be carboxy-terminated with maleic anhydride to synthesize polyether macromonomer allyl polyoxyethylene ether carboxylate. The polyether monomer is a new t...

Embodiment 2

[0018] The preparation method of water treatment purification agent, concrete steps are:

[0019] 1) Put maleic anhydride and allyl polyoxyethylene ether with a molar ratio of 1:9 into the reactor, stir at room temperature for 50 minutes, then heat to 70°C and stir for 3 hours to obtain the polyether monomer;

[0020]2) Put acrylic acid, polyether monomer, and 2-acrylamide-2-methylpropanesulfonic acid in a molar ratio of 3:0.2:0.7 into the reactor, and add chain transfer agent and monomer with a weight of 6% of the monomer 4% by weight of the initiator, then add distilled water, react at 80°C for 2 hours, and cool to room temperature to obtain a scale inhibitor with a solid content of 22%;

[0021] 3) In parts by weight, take 1.7 parts of carboxyethylthiosuccinic acid, 0.6 parts of sodium tartrate, 0.4 parts of zinc chloride, 0.7 parts of polyoxysuccinic acid, 0.5 parts of scale inhibitor, and 0.001 parts of sodium 4-aminobenzenesulfonate , and mix evenly to obtain a water tr...

Embodiment 3

[0023] The preparation method of water treatment purification agent, the specific steps are: put maleic anhydride and allyl polyoxyethylene ether with a molar ratio of 1:13 into a reactor, stir at room temperature for 60 minutes, and then heat to 60°C to stir and react 4h to obtain the polyether monomer; put acrylic acid, polyether monomer, and 2-acrylamide-2-methylpropanesulfonic acid in a molar ratio of 3:0.5:0.5 into the reactor, and add 10% of the monomer weight chain transfer agent and 2% initiator by monomer weight, then add distilled water, react at 60°C for 3h, and cool to room temperature to obtain a scale inhibitor with a solid content of 30%; take carboxyethylthiosuccinic acid 13g, sodium tartrate 8g, zinc sulfate 2g, polyoxysuccinic acid 7g, antiscalant 6g, sodium 4-aminobenzene sulfonate 0.02g, mix evenly to obtain water treatment purification agent, sodium tartrate in sodium tartrate and sodium tartrate The weight ratio of sodium tartrate is 1:0.08.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com