Process for manufacturing invisible pattern ceramic product

A ceramic product and pattern technology, which is applied in the field of manufacturing invisible pattern ceramic products, can solve the problems of glaze water accumulation, pattern deformation, disappearance, etc., and achieve the effects of increasing drying speed, uniform glaze layer thickness, and improving firing rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

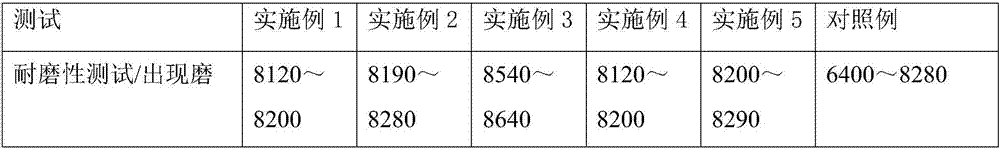

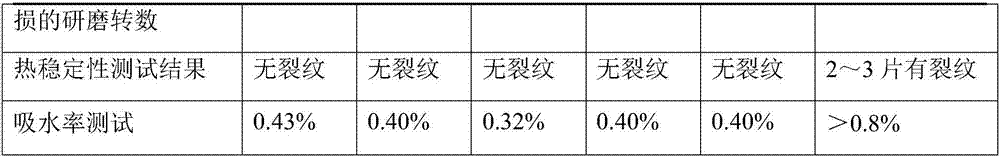

Examples

Embodiment 1

[0027] This embodiment provides a process for manufacturing ceramic products with invisible patterns, which is characterized in that it includes the following steps:

[0028] Step 1: Mix kaolin with water at a weight ratio of 1:2, stir at a rate of 200r / min for 2 hours, after standing for clarification, remove the precipitated sludge from the lower layer and ball mill at a rate of 60r / min for 1 hour, Cross 100 mesh sieves afterwards to obtain fine mud, adjust the water content of fine mud to 40%, and then shape it under a pressure of 6MPa to obtain a rough green body, and obtain the green body after sharpening the green body;

[0029] Step 2: Mix 20 parts by weight of kaolin, 20 parts by weight of silicon oxide, 15 parts of aluminum oxide, 10 parts by weight of wollastonite, and 8 parts by weight of cobalt blue material, add water ball mill, and then pass through a 1200-mesh sieve. Adjust its water content to 65% to obtain glaze water;

[0030] Step 3: After the whole body is...

Embodiment 2

[0032] This embodiment provides a process for manufacturing ceramic products with invisible patterns, which is characterized in that it includes the following steps:

[0033] Step 1: Mix kaolin with water at a weight ratio of 1:2, stir at a rate of 250r / min for 1.5 hours, after standing for clarification, remove the precipitated sludge from the lower layer and ball mill at a rate of 70r / min for 1 hour, Cross 200 mesh sieves afterwards to obtain fine mud, adjust the water content of fine mud to 40% and then shape under a pressure of 7MPa to obtain a rough green body, and obtain a green body after sharpening the green body;

[0034]Step 2: Mix 22 parts by weight of kaolin, 20 parts by weight of silicon oxide, 17 parts of alumina, 10 parts by weight of wollastonite, and 10 parts by weight of manganese oxide pigment, add water ball mill, and then pass through a 1300-mesh sieve to adjust Its water content is 65%, and the glaze water is obtained;

[0035] Step 3: After the whole bo...

Embodiment 3

[0037] This embodiment provides a process for manufacturing ceramic products with invisible patterns, which is characterized in that it includes the following steps:

[0038] Step 1: Mix kaolin with water at a weight ratio of 1:3, stir at a rate of 250r / min for 2 hours, after standing for clarification, remove the precipitated sludge from the lower layer and ball mill at a rate of 80r / min for 2 hours, Cross 350 mesh sieves afterwards, obtain fine mud, adjust the water content of fine mud to 45% and then shape under the pressure of 7.5MPa to obtain the rough green body, and obtain the green body after sharpening the green body;

[0039] Step 2: After mixing 22 parts by weight of kaolin, 23 parts by weight of silicon oxide, 17 parts of aluminum oxide, 13 parts by weight of wollastonite, and 13 parts by weight of iron oxide red pigment, add water ball mill, and then pass through a 1450 mesh sieve. Adjust its water content to 68% to obtain glaze water;

[0040] Step 3: The green ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com