Colorful art brick prepared from waste ceramic glaze water and preparation method thereof

A ceramic waste and control method technology, which is applied in the production of ceramic materials, clay products, adaptive control, etc., can solve problems such as high cost, high energy consumption, and environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

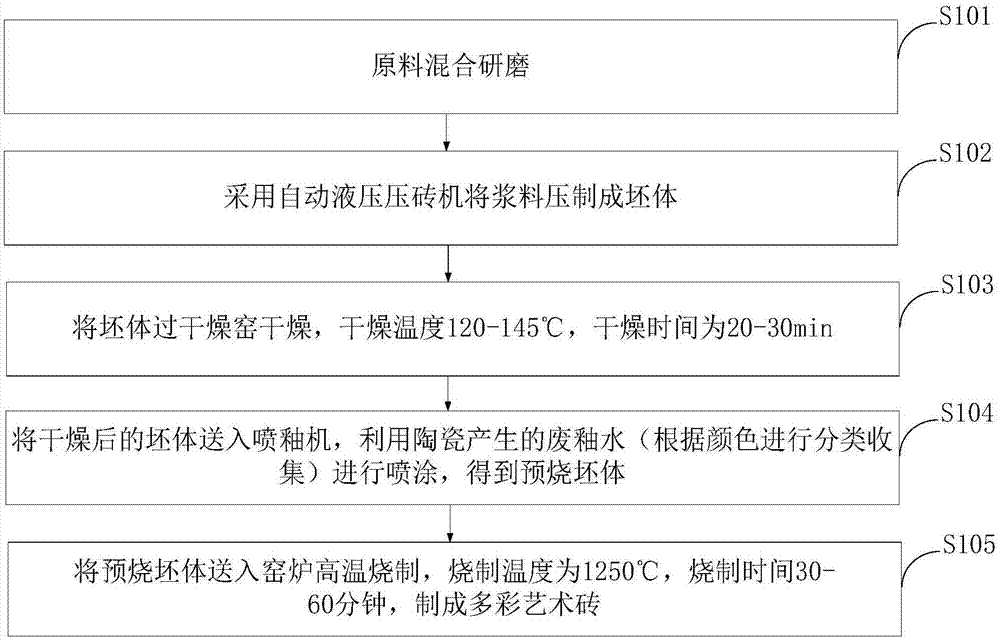

Method used

Image

Examples

Embodiment 1

[0132]本发明提供实施例提供的陶瓷废釉水制备多彩艺术砖由如下质量组分的原料制成:

[0133]陶瓷企业的高岭土尾矿20份、中低温废陶瓷制品18份、陶瓷企业收集沉淀池泥浆10份、建筑工地固废22份、环氧固化剂5份、熔块28份、石英粉4份,长石粉4份、硅酸锆6份、废釉水6份、羧甲基纤维素0.04~0.06份、三聚磷酸钠0.6~0.8份、水80~150份、氧化铁0.1~1份、氧化钛0.1~1份、增色剂2~10份

Embodiment 2

[0135]本发明提供实施例提供的陶瓷废釉水制备多彩艺术砖由如下质量组分的原料制成:

[0136]陶瓷企业的高岭土尾矿30份、中低温废陶瓷制品22份、陶瓷企业收集沉淀池泥浆20份、建筑工地固废32份、环氧固化剂10份、熔块32份、石英粉6份,长石粉6份、硅酸锆10份、废釉水10份、羧甲基纤维素0.04~0.06份、三聚磷酸钠0.6~0.8份、水80~150份、氧化铁0.1~1份、氧化钛0.1~1份、增色剂2~10份

Embodiment 3

[0138]本发明提供实施例提供的陶瓷废釉水制备多彩艺术砖由如下质量组分的原料制成:

[0139]陶瓷企业的高岭土尾矿25份、中低温废陶瓷制品20份、陶瓷企业收集沉淀池泥浆15份、建筑工地固废27份、环氧固化剂7.5份、熔块30份、石英粉5份,长石粉5份、硅酸锆8份、废釉水8份、羧甲基纤维素0.04~0.06份、三聚磷酸钠0.6~0.8份、水80~150份、氧化铁0.1~1份、氧化钛0.1~1份、增色剂2~10份。

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap