Preparation method of compound waterborne anticorrosive coating

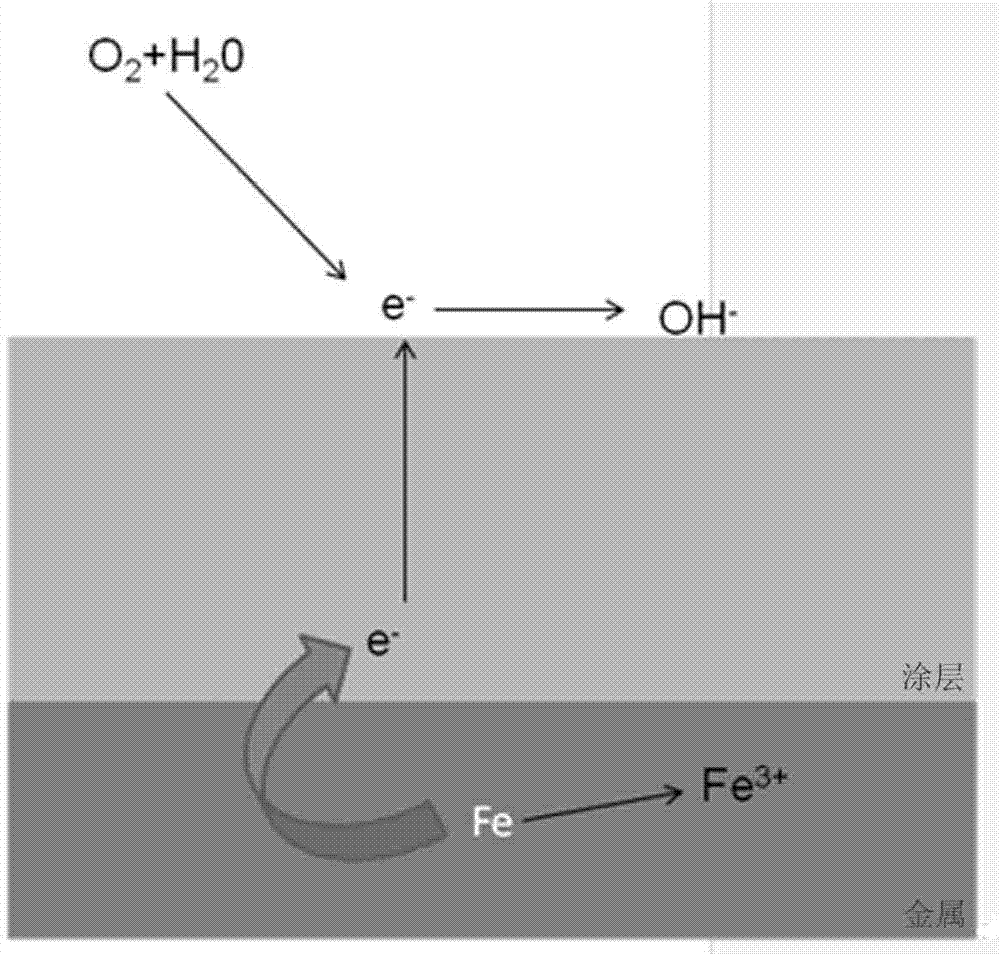

A water-based technology for anti-corrosion coatings, applied in anti-corrosion coatings, epoxy resin coatings, coatings, etc., can solve the problems of reduced strength, decreased anti-corrosion performance, poor barrier properties, etc., to promote metal corrosion, intensify corrosion, and high porosity rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] The preparation method of composite water-based anticorrosion coating comprises the following steps.

[0022] 1. Preparation of conductive filler.

[0023] (1) Weigh 8g of aniline hydrochloride into a three-neck flask, add 40mL of deionized water, stir for 40min at a stirring speed of 500 r / min to obtain solution I; weigh 13g of ammonium persulfate into a beaker, add 60mL of deionized In water, stir for 40 min at a stirring speed of 500 r / min to obtain solution II; place solution I and solution II in an ice-water bath for 40 min to lower the temperature to 10°C; then add solution II to the solution at a rate of 5 mL / s In I, stir rapidly and vigorously for 2min at a stirring speed of 1500r / min to obtain solution III; leave solution III at room temperature for 15h to obtain polyaniline hydrogel, and use 500mL of 0.2 mol / Wash with 1 L HCl, replace HCl every 10h, and wash for 6 days; then use 500mL absolute ethanol for solvent replacement, replace absolute ethanol every 1...

Embodiment 2

[0032] The preparation method of the water-based anticorrosion coating without adding any filler comprises the following steps.

[0033] (1) Mix 100 parts of Ar555 water-based epoxy resin and 100 parts of water evenly to obtain a resin system.

[0034] (2) Mix 50 parts of H228B water-based curing agent with 100 parts of water evenly; mix the resin system and the diluted water-based curing agent in a weight ratio of 4:1 to get the product.

[0035] Coat the obtained anti-corrosion coating on the treated metal substrate, control the thickness at 30-200um, and cure at room temperature for 24 hours.

Embodiment 3

[0037] The preparation method of the water-based anti-corrosion paint added with conductive metal organic framework includes the following steps.

[0038] 1. Preparation of conductive filler.

[0039] (1) Weigh 0.2mL of titanium tetrachloride and dissolve it in 70mL of cold water, add 0.3g of the metal-organic framework (MIL-101(Cr)) prepared in Example 1, stir for 30min at a stirring speed of 300r / min, and stir After centrifugation for 5 minutes, the centrifugal speed is 3000r / min, remove the precipitate obtained from the supernatant and add 100mL deionized water, then transfer to the reaction kettle, hydrothermal reaction at 160°C for 8h; then centrifugal washing, the centrifugal speed is 3000r / min, and the precipitate was dried under vacuum at 40°C for 10 h to obtain a conductive metal-organic bone (MIL-101(Cr)@TiO 2 ).

[0040] 2. Preparation of anti-corrosion coatings.

[0041] (1) Take 100 parts of Ar555 water-based epoxy resin and 100 parts of water, and mix them ev...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com