A kind of antifreeze material with controllable slow release rate applied to concrete pavement and preparation method thereof

A technology for concrete pavement and antifreeze material, which is applied in chemical instruments and methods, other chemical processes, etc., to achieve the effect of reducing damage, environment-friendly dosage, and ensuring safe and smooth flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

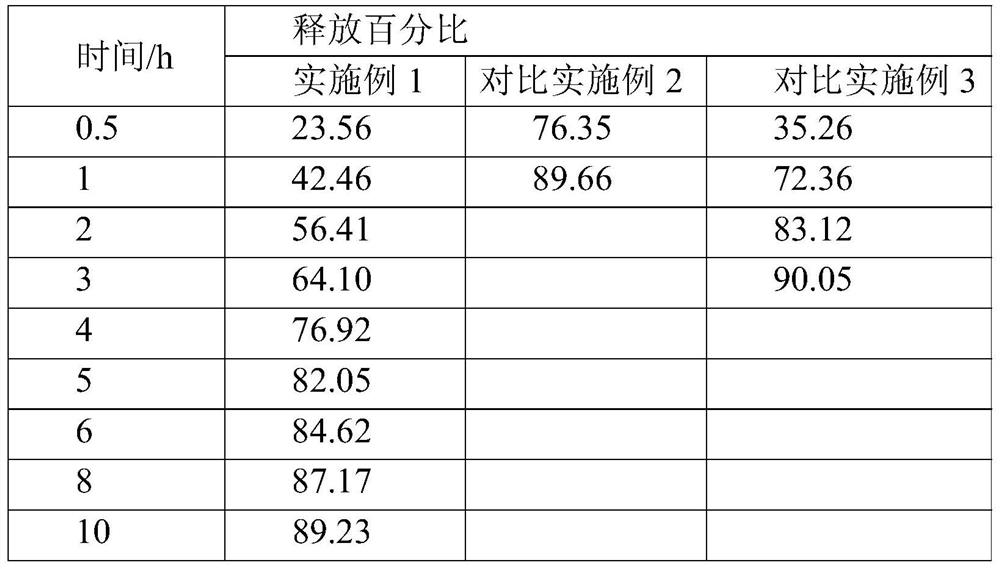

Examples

Embodiment 1

[0026] Weigh 80g of sodium chloride and 4g of calcium chloride;

[0027] Rust inhibitor 1g: zinc dihydrogen phosphate 0.2g, sodium tungstate 0.25g, thiourea 0.25g, tetraethylene pentamine 0.1g, sodium dodecylbenzenesulfonate 0.2g;

[0028] Cross-linked polymer material 5g: Among them, epoxy resin 2g, phenolic resin 3g;

[0029] Waterproof coating 10g: talc 4g, calcium carbonate 4g, hydroxypropyl methylcellulose 2g;

[0030] The specific steps of the preparation method are:

[0031] (1) first put sodium chloride, calcium chloride and rust inhibitor together into a pulverizer to pulverize and mix, spray a certain amount of water, and then granulate through a granulation equipment to obtain core material particles;

[0032] (2) Stir the core material particles obtained in step (1) under the condition of blasting hot air until the core material is heated to 50°C, add 2.5 g of cross-linked polymer material and stir for 5 minutes, and then add waterproofing under the condition of ...

Embodiment 2

[0035] Weigh 75g of sodium chloride and 4g of calcium chloride.

[0036] 1 g of rust inhibitor: wherein, zinc dihydrogen phosphate 0.2 g, sodium tungstate 0.25 g, thiourea 0.25 g, tetraethylene pentamine 0.1 g, and sodium dodecylbenzenesulfonate 0.2 g.

[0037] 10 g of cross-linked polymer material: 5 g of phenolic resin and 5 g of acrylic resin.

[0038] Waterproof coating 10g: Among them, talc 4g, calcium carbonate 4g, hydroxypropyl methylcellulose 2g.

[0039] The preparation method is shown in Example 1.

Embodiment 3

[0041] Weigh 70 g of sodium chloride and 4 g of calcium chloride.

[0042] 1 g of rust inhibitor: wherein, zinc dihydrogen phosphate 0.2 g, sodium tungstate 0.25 g, thiourea 0.25 g, tetraethylene pentamine 0.1 g, and sodium dodecylbenzenesulfonate 0.2 g.

[0043] 15 g of cross-linked polymer material: 7 g of epoxy resin and 8 g of acrylic resin.

[0044] Waterproof coating 10g: Among them, talc 4g, calcium carbonate 4g, hydroxypropyl methylcellulose 2g.

[0045] The preparation method is shown in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com