Anti-wear agent for diesel oil

An anti-wear agent and diesel technology, applied in the field of diesel anti-wear agent, can solve problems such as low acid value, and achieve the effects of simple preparation method, improved lubricating performance and mild production conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

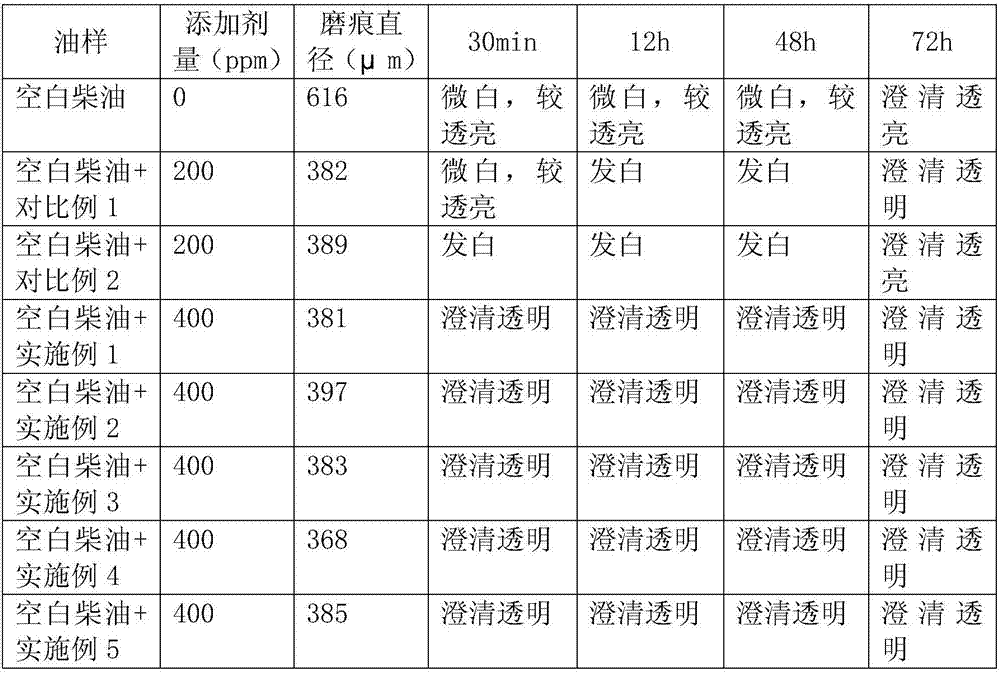

Examples

Embodiment 1

[0021] Preparation of polysiloxane-allyl polyoxyethylene polyoxypropylene methyl ether: 40g isopropanol is used as solvent, polymethyl hydrogen siloxane 50g is reacted with allyl polyoxyethylene polyoxypropylene methyl ether 35g , using 0.1% chloroplatinic acid as a catalyst by mass ratio, the reaction temperature is 80°C, the reaction time is 7h, nitrogen gas is passed through during the reaction, and the solvent isopropanol is distilled off under reduced pressure after the reaction, and the yellow transparent liquid is polysiloxane Alkyl-allyl polyoxyethylene polyoxypropylene methyl.

[0022] Take linoleic acid glyceride, tert-amyl alcohol and polysiloxane-allyl polyoxyethylene polyoxypropylene methyl ether and mix evenly, linoleic acid glyceride, tert-amyl alcohol and polysiloxane-allyl polyoxyethylene The weight ratio of polyoxypropylene methyl ether is 50:40:10, the mixing temperature is 30°C, and the mixing method is to first add linoleic acid glyceride to tert-amyl alco...

Embodiment 2

[0024] The preparation method of polysiloxane-allyl polyoxyethylene polyoxypropylene methyl ether is the same as that of Example 1, taking linoleic acid glyceride, tert-amyl alcohol and polysiloxane-allyl polyoxyethylene polyoxypropylene The methyl ether is mixed evenly, the weight ratio of glyceryl linoleate, tert-amyl alcohol and polysiloxane-allyl polyoxyethylene polyoxypropylene methyl ether is 45:55:10, and the mixing temperature is 40°C. First add glyceryl linoleate to tert-amyl alcohol, and finally add polysiloxane-polyoxyethylene polyoxypropylene methyl ether.

Embodiment 3

[0026] The preparation method of polysiloxane-allyl polyoxyethylene polyoxypropylene methyl ether is the same as that of embodiment 1, and oleic acid glyceride, tert-amyl alcohol and polysiloxane-allyl polyoxyethylene polyoxypropylene methyl ether are obtained The base ether is mixed evenly, the weight ratio of glyceryl oleate, tert-amyl alcohol and polysiloxane-allyl polyoxyethylene polyoxypropylene methyl ether is 48:40:12, the mixing temperature is 50°C, and the mixing method is first Add glyceryl oleate to tert-amyl alcohol, and finally polysiloxane-polyoxyethylene polyoxypropylene methyl ether.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com