A method of manufacturing a planar thermoelectric element

A technology of thermoelectric elements and manufacturing methods, applied in the manufacture/processing of thermoelectric devices, thermoelectric devices that only use the Peltier or Seebeck effect, etc., can solve problems such as the limitation of refrigeration effects, and achieve compact circuit structure, high energy density, and optimized Effect of thermoelectric conversion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

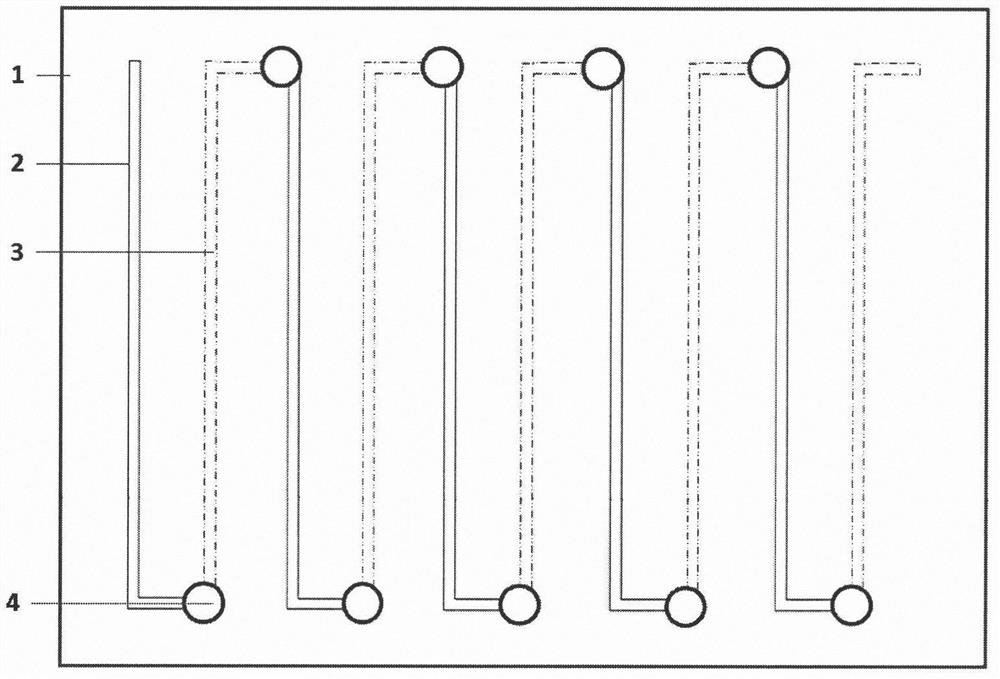

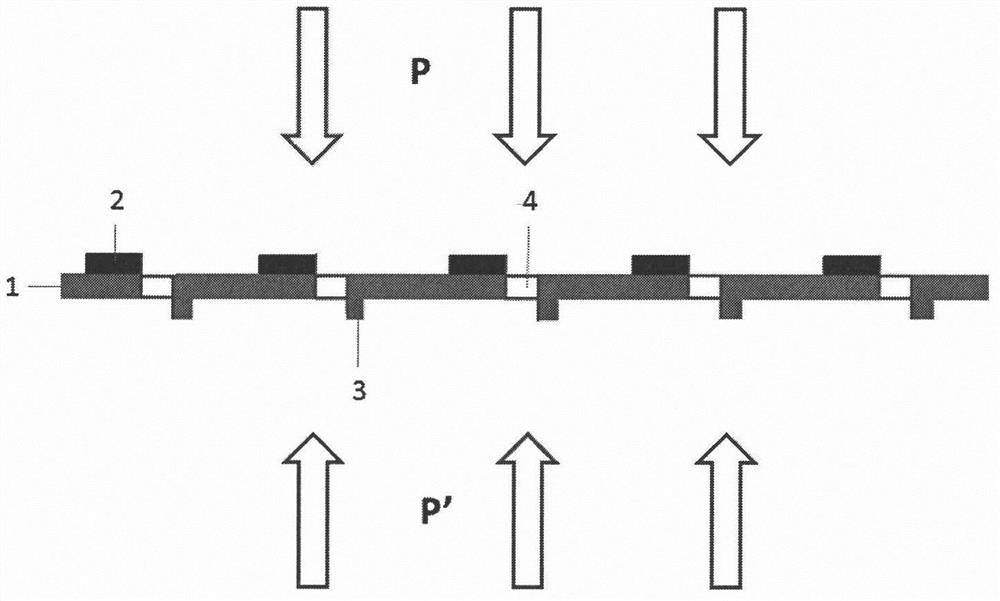

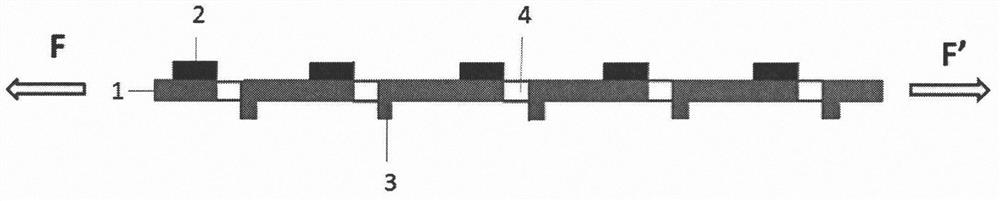

[0018] Lead zirconate titanate piezoelectric ceramics are used as the substrate, and N-type Bi is magnetron sputtered through the mask on the front. 0.5 Sb 1.5 Te 3 Circuit layer of thermoelectric material, P-type Bi sputtered by mask magnetron sputtering on the back 2 Te 2.7 Se 0.3 For the circuit layer of thermoelectric materials, through holes are drilled at the end of the circuit, and copper is electroplated in the through holes to form an alternating series circuit structure of N-P-N-P.... The planar structure is as follows figure 1 shown. When the series circuit is fed with current, one side of the substrate can be cooled and the other side can dissipate heat, forming a temperature difference; when there is a temperature difference between the two ends of the substrate, a potential difference is generated in the alternating series circuit structure, which can convert the temperature difference into electrical energy and output it outward. In the process of thermoele...

Embodiment 2

[0020] Using lead magnesium niobate piezoelectric ceramics as the substrate, the circuit layer of N-type PbTe thermoelectric material vacuum-evaporated through a mask on the front, and the circuit layer of P-type PbSe thermoelectric material vacuum-evaporated through a mask on the back, at the end of the line Drill through holes, electroplate copper in the through holes to form an alternating series circuit structure of N-P-N-P..., the planar structure is as follows figure 1 shown. When the series circuit is fed with current, one side of the substrate can be cooled and the other side can dissipate heat, forming a temperature difference; when there is a temperature difference between the two ends of the substrate, a potential difference is generated in the alternating series circuit structure, which can convert the temperature difference into electrical energy and output it outward. In the process of thermoelectric or electrothermal conversion, normal pressure is applied to the...

Embodiment 3

[0022] P(VDF-TrFE) piezoelectric polymer is used as the substrate, and the N-type poly-3,4 ethylenedioxythiophene: polydiallyldimethylammonium chloride thermoelectric material circuit layer is screen-printed on the front On the back, the circuit layer of polyphenylpyrrole thermoelectric material is filled with P-type graphene printed on the screen, through-holes are drilled at the end of the circuit, and copper is electroplated in the through-holes to form an alternating series circuit structure of N-P-N-P.... The planar structure is as follows figure 1 shown. When the series circuit is fed with current, one side of the substrate can be cooled and the other side can dissipate heat, forming a temperature difference; when there is a temperature difference between the two ends of the substrate, a potential difference is generated in the alternating series circuit structure, which can convert the temperature difference into electrical energy and output it outward. In the process o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com