A kind of method of lepidolite multistage suspension roasting defluorination

A suspension roasting and suspension roasting furnace technology, applied in chemical instruments and methods, climate sustainability, inorganic chemistry, etc., can solve the problems of large amount of water vapor, large steam consumption, high energy consumption, etc., to increase contact area, improved defluorination rate, and short defluorination time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

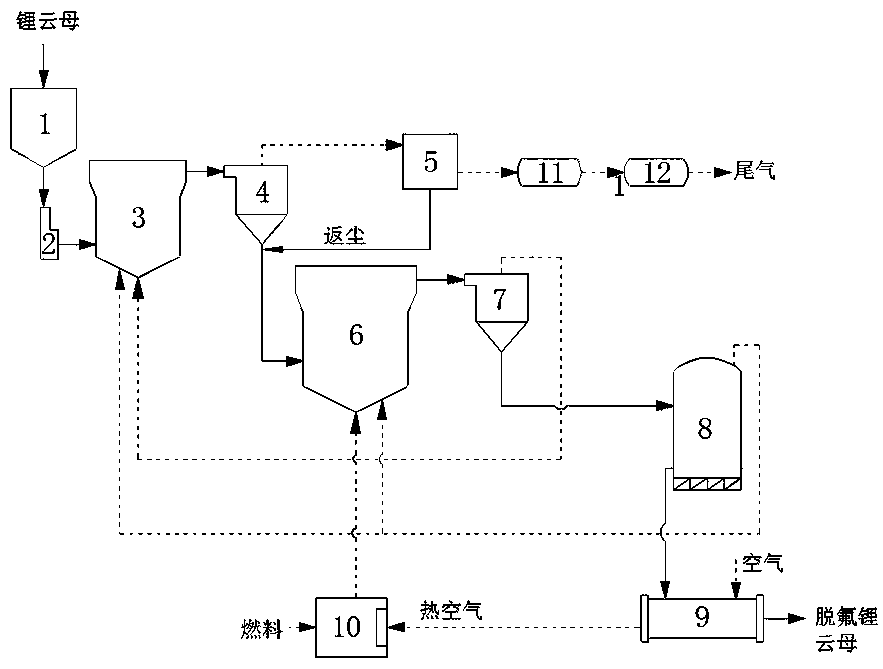

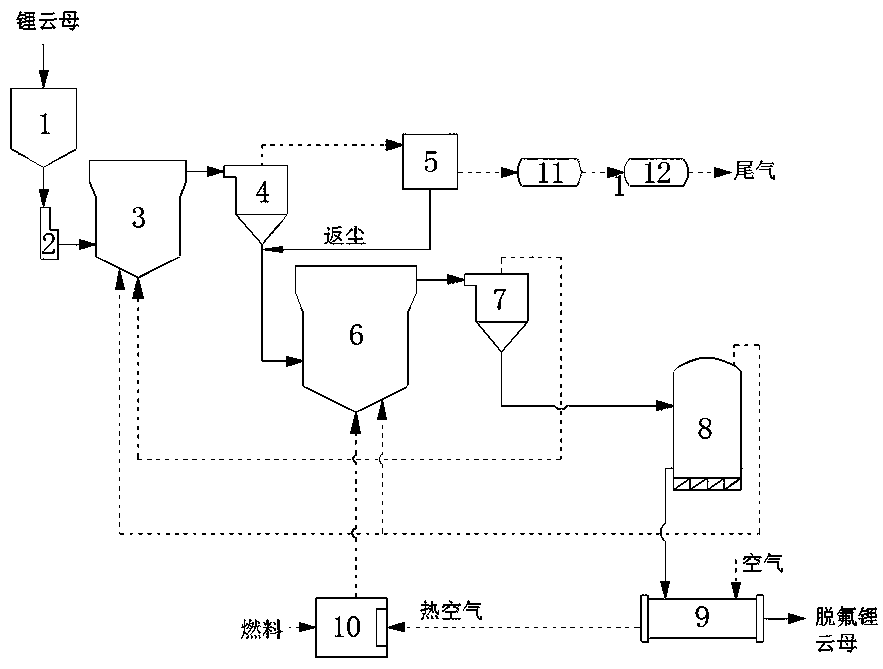

[0028] Such as figure 1 Shown, the method for lepidolite multistage suspension roasting defluorination of the present invention specifically comprises the following steps:

[0029] 1) Grinding the lepidolite ore with the crusher 1 to a certain particle size to obtain lepidolite ore powder;

[0030] 2) The lepidolite ore powder obtained in step 1) is put into the secondary suspension roaster 3 through the screw hopper 2, and the exhaust gas collected by the primary cyclone dust collector 7 and the defluorination from the insulation tank 8 are introduced. Tail gas is subjected to suspension roasting, drying and preheating;

[0031] 3) The preheated lepidolite mineral powder and gas are separated by the secondary cyclone dust collector 4, and the lepidolite mineral powder and tail gas are obtained after separation; the obtained tail gas also contains a small amount of mineral powder, which needs to be further dedusted in the dust collector 5. The obtained mineral powder is retu...

Embodiment 2

[0037] Put the lepidolite ore powder that is ground to a particle size of 1mm, a water content of 15wt%, a lithium oxide content of 3.43wt%, and a fluorine content of 1.8wt% into the secondary suspension roaster, and pass it through the primary The high-temperature tail gas (830°C) collected by the cyclone after the suspension roaster is subjected to suspension roasting and drying and preheated to a temperature of 600°C, the preheating time is 3s, and the air velocity of the gas in the secondary suspension roaster is 3m / s; The heated lepidolite powder and tail gas are separated by a secondary cyclone dust collector to obtain lepidolite powder and tail gas. The obtained mineral powder and high-temperature combustion gas with a water vapor content of 40wt% from the combustion chamber (950°C ) and supplementary water vapor are quickly mixed in the first-level suspension roaster for rapid defluorination by suspension roasting. s; After defluorination is completed, it enters the fi...

Embodiment 3

[0039] Put the lepidolite ore powder that is ground to a particle size of 1mm, a water content of 10wt%, a lithium oxide content of 3.43wt%, and a fluorine content of 1.8wt% into the secondary suspension roaster, and pass it through the primary The high-temperature tail gas (750°C) collected by the cyclone after the suspension roaster is subjected to suspension roasting and drying and preheated to a temperature of 500°C, the preheating time is 8s, and the air velocity of the gas in the secondary suspension roaster is 8m / s; The heated lepidolite ore powder and tail gas are separated by a secondary cyclone dust collector to obtain lepidolite ore powder and tail gas. The obtained ore powder and high-temperature combustion gas with a water vapor content of 30wt% from the combustion chamber (980°C ) and supplementary water vapor are quickly mixed in the first-level suspension roaster for rapid defluorination by suspension roasting. s; after defluorination is completed, it enters th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com