Method for purifying unsaturated fatty acid and eicosapentaenoic acid

A technology of unsaturated fatty acids and eicosapentaenoic acid, applied in the field of purification, can solve problems such as large silver nitrate, difficulty in obtaining high-purity EPA-EE and DHA-EE, difficulty in recycling silver nitrate, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] Embodiment 1: the purification of unsaturated fatty acid

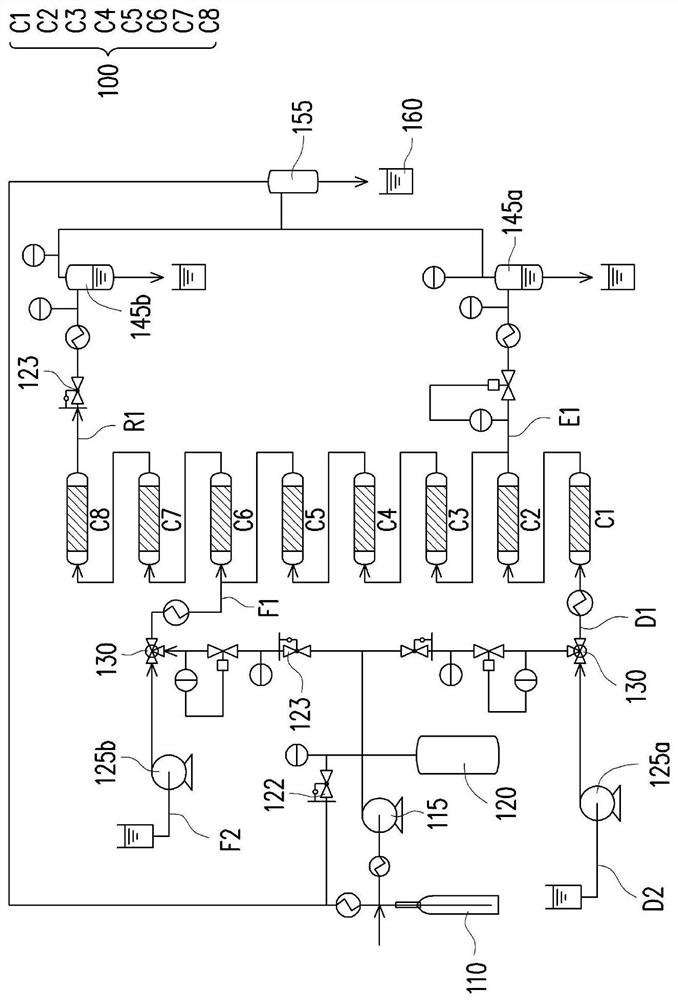

[0045] In this example, you can use figure 1 The supercritical fluid-simulated moving bed (Supercritical Fluid-Simulated Moving Bed, SF-SMB) equipment shown is used to perform simulated moving bed chromatography. figure 1 It is a pipeline flow chart of a supercritical fluid simulated moving bed equipment according to an embodiment of the present invention. Please refer to figure 1 , the simulated moving bed 100 includes a first section, a second section and a third section. In this embodiment, the first section includes two pipe strings C1 and C2, the second section includes three pipe strings C3, C4, and C5, and the third section includes three pipe strings C6, C7, and C8. Eight pipe strings are connected in series, but the present invention is not limited thereto. In another embodiment, the first section includes 2 pipe strings, the second section includes 2 pipe strings, the third section includes 2 pipe ...

experiment example 1

[0066] [Operating conditions of SF-SMB]

[0067] In Experimental Example 1, 10% ethylated fish oil raw material (Changzhou Jiazhong New Material Technology Co., Ltd.) was first prepared into a 20 g / L ethanol solution. Next, use something like figure 1 The shown supercritical fluid simulates a moving bed device for the purification of unsaturated fatty acids including EPA and DHA. and figure 1 The only difference in the supercritical fluid simulated moving bed equipment is that in Experimental Example 1, 6 packed columns are used and designed as a simulated moving bed with three sections. The packed column is a 10mm×150mm stainless steel column, the filler (stationary phase) used is random silica, and the mobile phase is a washing agent comprising supercritical carbon dioxide and 5wt% pure ethanol. Six packed columns are designed as a three-section simulated moving bed, and each section has two columns. The separation conditions are as follows: the temperature is fixed at 5...

experiment example 2

[0072] Adopt the same equipment and conditions as Experimental Example 1 to carry out the purification, the difference is only that 25% ethylated fish oil raw material is made into 10 g / liter ethanol solution, and five different switching times (2 minutes 50 seconds, 2 minutes 55 seconds, 3 minutes, 3 minutes 20 seconds, and 3 minutes 40 seconds) tests. Using the above conditions to carry out the simulated moving bed chromatography obtained results analysis as follows Figure 7 to Figure 11 Shown, and by formula 1 and formula 2 calculated content (defined as purity) and the result of recovery rate are shown in table 2.

[0073] Table 2

[0074]

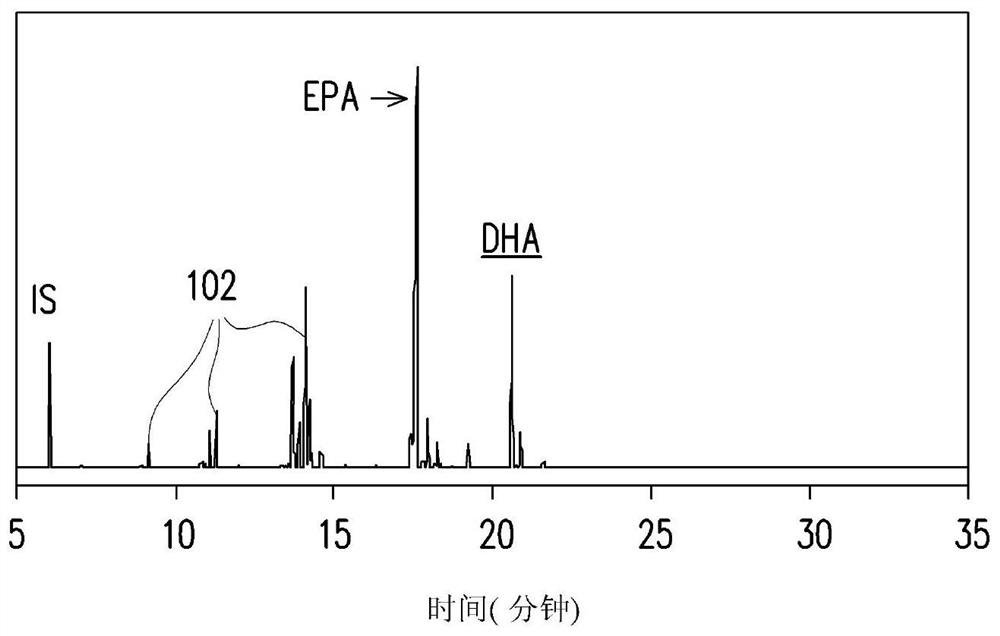

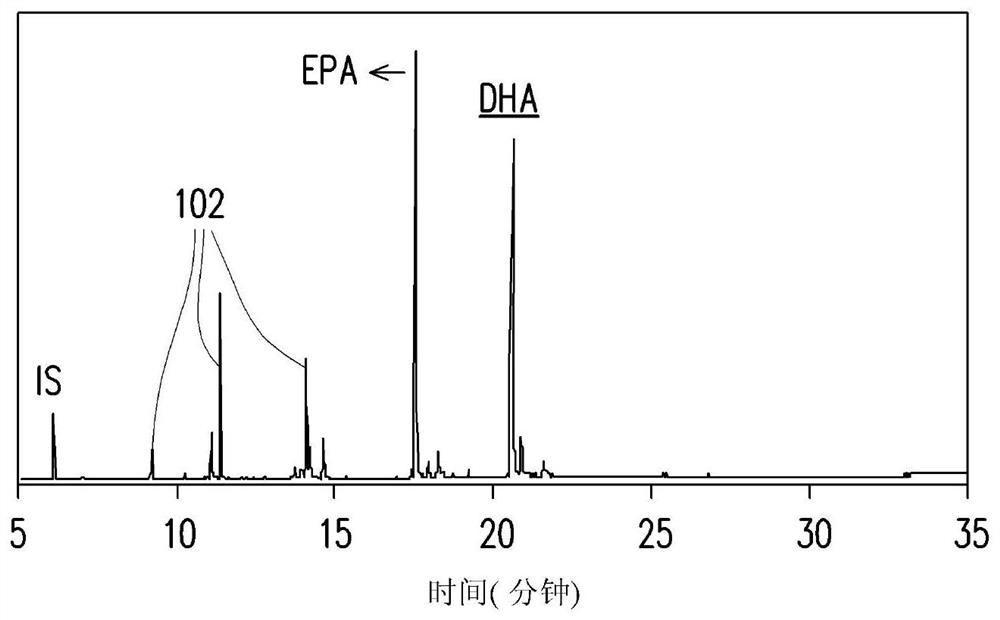

[0075] Figure 7 to Figure 11 It is an analysis diagram of the result of separating and purifying unsaturated fatty acids including EPA and DHA from 25% fish oil by using simulated moving bed chromatography in the experimental example of the present invention. Please refer to Figure 7 to Figure 11 and Table 2. Depend on Fig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com