Technology for eliminating withdrawing and straightening lines on surface of galvanized door plate steel

A door plate steel and process technology, applied in the field of eliminating the surface tension and straightening of galvanized door plate steel, can solve the problems of serious surface tension and straightening, the treatment and control are not fully effective, and improve product quality and quality, and the surface quality is good. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

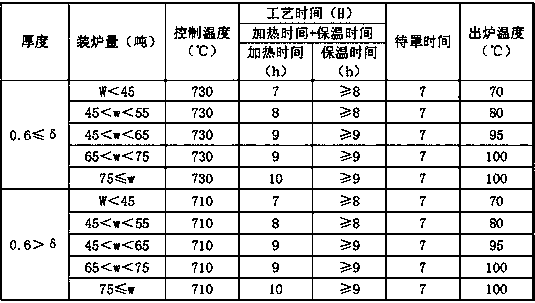

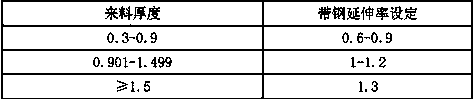

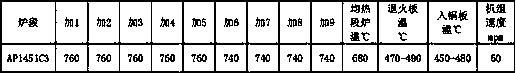

[0020] A process for eliminating stretch marks on the surface of galvanized door panel steel, the selected process route is: pickling-rolling mill-bell annealing-levelling-galvanizing;

[0021] 1) The percentage by weight of each chemical composition in the selected galvanized door panel steel is C ≤0.01, Si ≤0.04, Mn 0.15-0.25, P ≤0.02, S ≤0.015, Al 0.015-0.055, N ≤0.004, B 0.001- 0.002;

[0022] 2) Cold-rolled pickling, routine control points of rolling mill: control of cold-rolling pickling solution, to ensure that the oxide iron scale on the surface of the strip is pickled clean, and the most important point of the cold-rolling mill is to ensure that the purge pressure at the outlet of the 5# rolling mill shall not be less than 5 kg ;The heating temperature of the conventional hot rolling process is 1125-1185°C, the final rolling temperature is 870±20°C, the cooling mode is rapid cooling in the rear section, and the curling temperature is 640±20°C; the main points of the b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com