Pre-dedusting, desulfuration and denitration integrated processing device and method

A treatment device and pre-dust removal technology, applied in chemical instruments and methods, separation methods, dispersed particle separation, etc., can solve the problems of easy blocking utilization of carbon-based catalysts, low system denitration efficiency, complex equipment structure, etc., to solve production problems. The effect of load cycle change, increasing flue gas treatment capacity, and improving catalytic efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] Preferred embodiments of the present invention will be described in detail below.

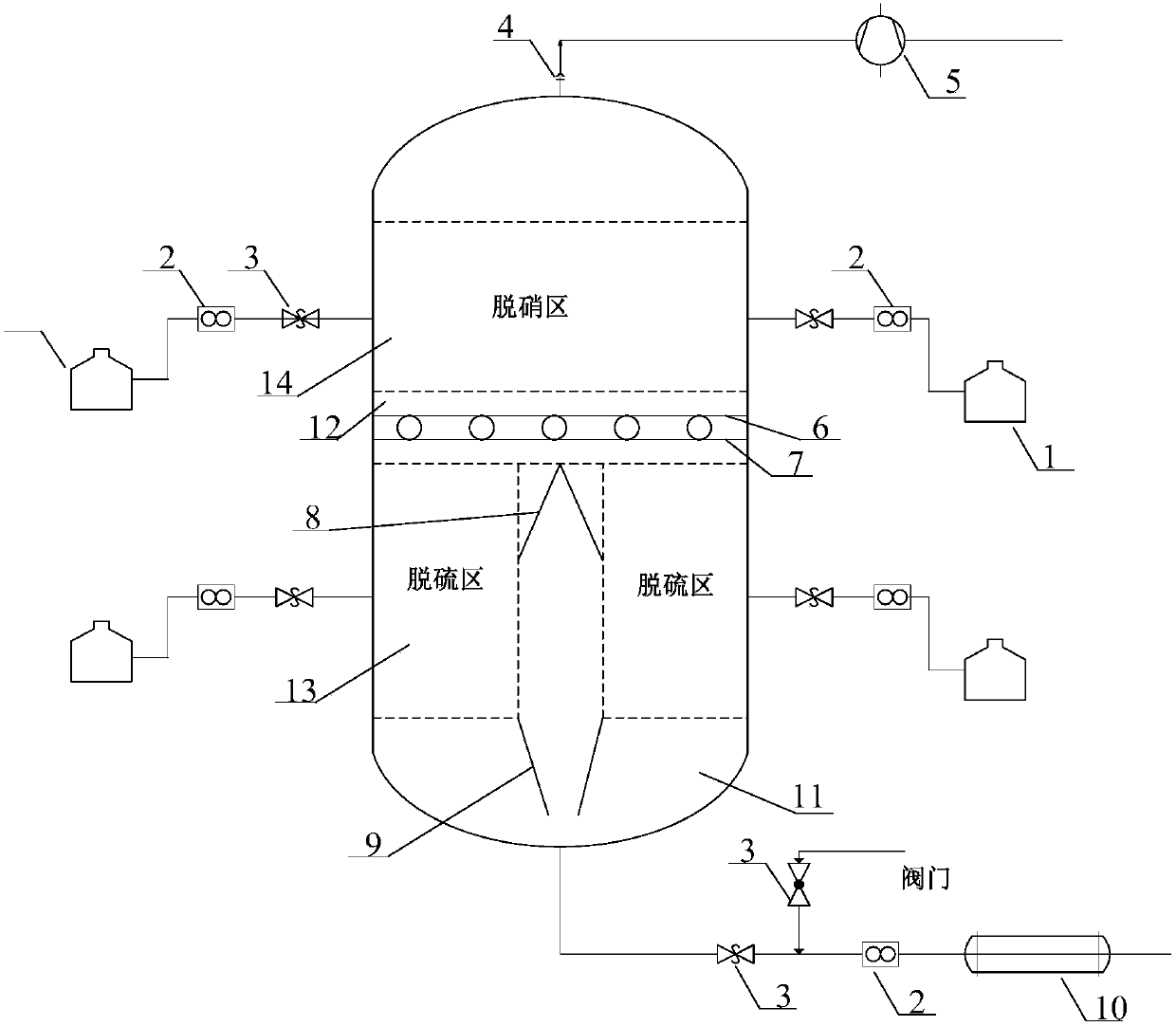

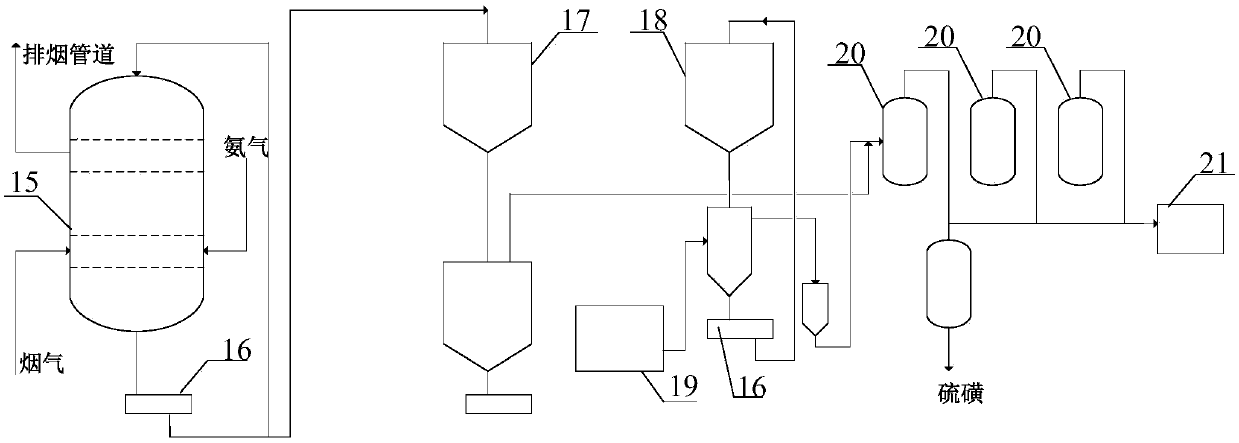

[0031] The reference signs in the accompanying drawings of the specification include:

[0032] Liquid ammonia storage tank 1, flow meter 2, regulating valve 3, explosion relief valve 4, induced draft fan 5, rectifying plate 6, equalizing plate 7, deflector plate 8, ash collecting hopper 9, flue gas heat exchanger 10, preheating Dust removal area 11, buffer zone 12, desulfurization area 13, denitrification area 14, integrated reaction tower 15, screening device 16, mobile silo 17, regeneration tower 18, fuel bin 19, sulfur recovery tower 20, gas collection tower 21.

[0033] like figure 1 The shown industrial kiln pre-dust removal, desulfurization and denitrification integrated device includes a pre-dust removal area 11, a desulfurization area 13, a buffer area 12 and a denitrification area 14 which are connected sequentially from bottom to top and separated by a baffle with an air outle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com