Device and method for purifying waste gas containing VOCs by membrane aeration biological membrane reactor

A membrane aeration biofilm and biological reaction technology is applied in the field of membrane aeration biofilm reactors to purify waste gas containing VOCs, which can solve the problems of easy blockage of filter towers, low waste gas removal rate, etc., and achieve high VOCs removal. efficiency, simple device structure, and the effect of reducing processing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] A method for purifying waste gas containing VOCs by a membrane aerated biofilm reactor, comprising the steps of:

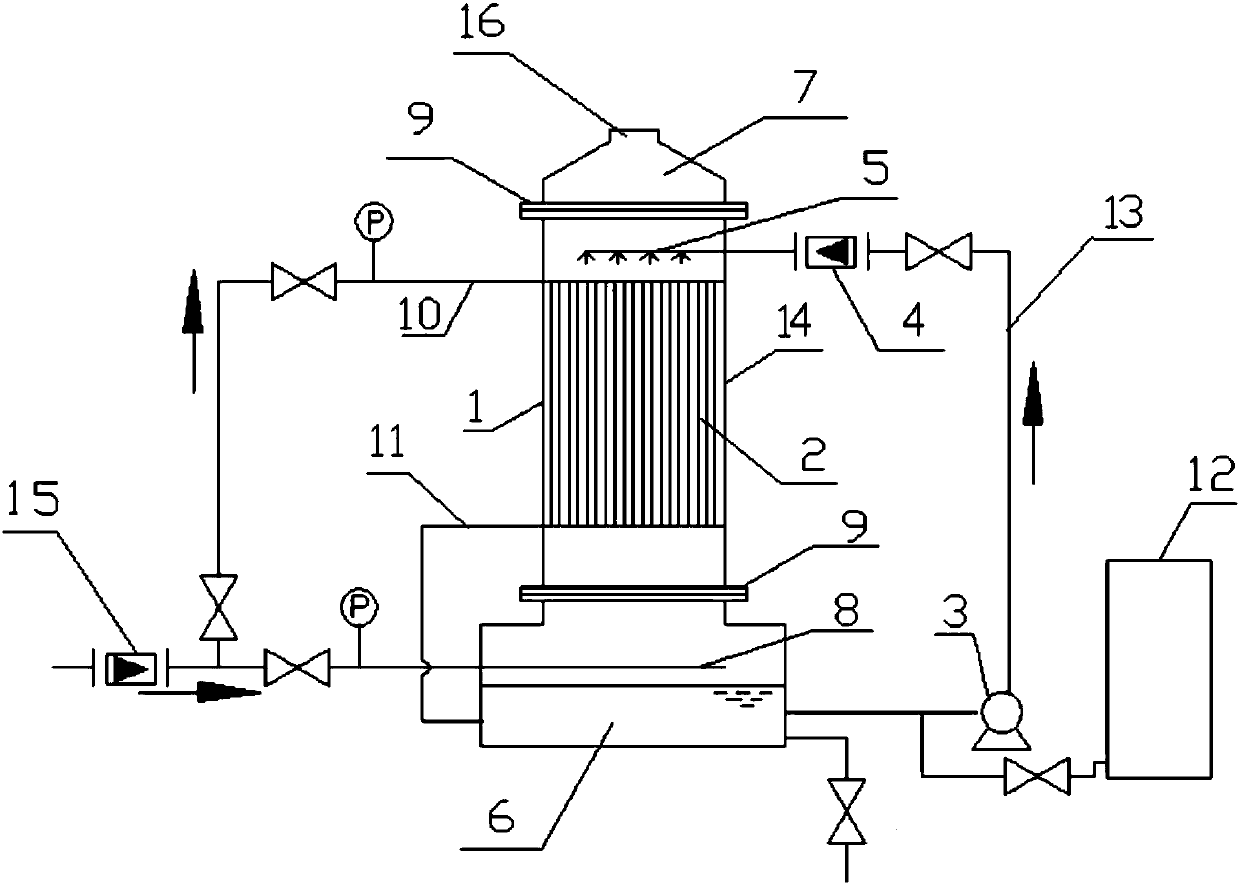

[0040] (1) A device for purifying waste gas containing VOCs using a membrane aerated biofilm reactor;

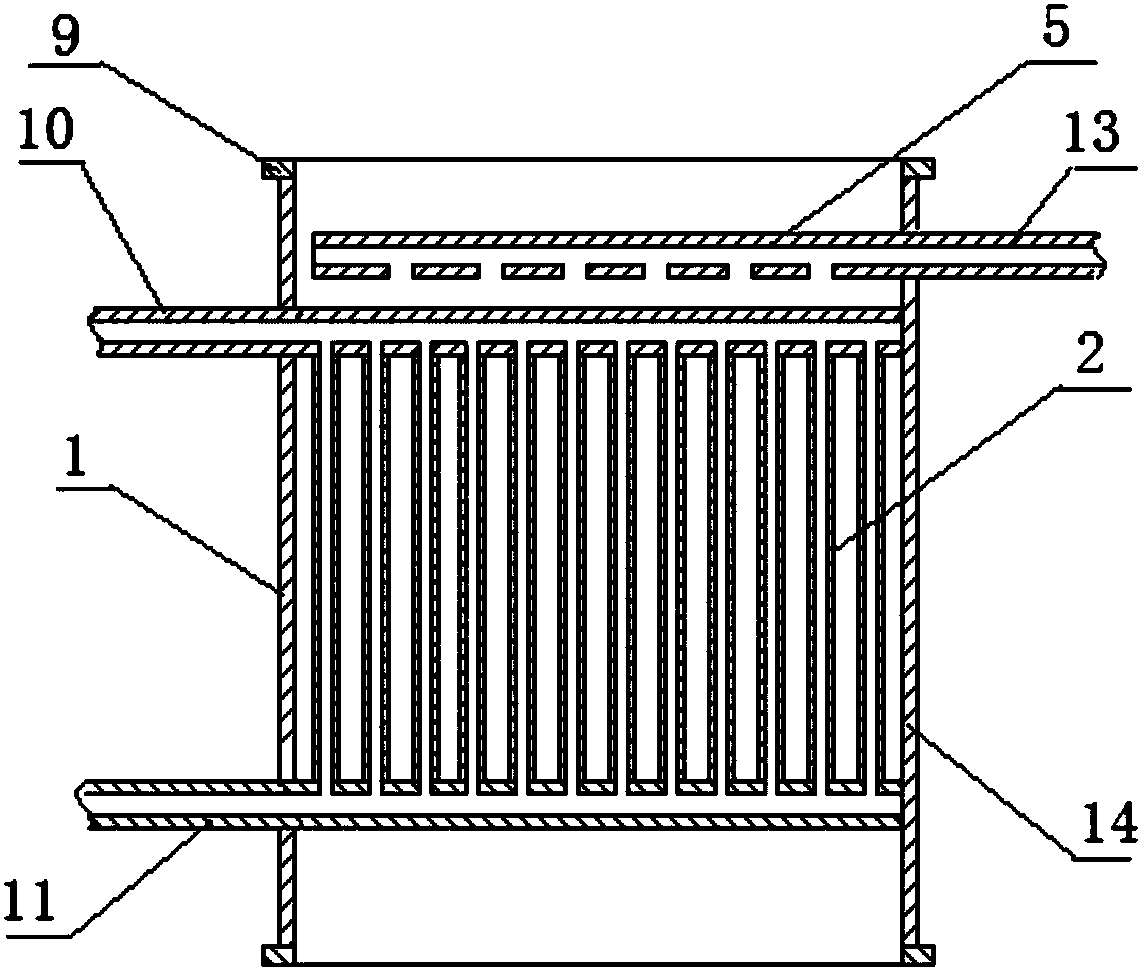

[0041] (2) bio-filming the outer surface of the hollow fiber membrane module 2 provided in the bioreaction module 14;

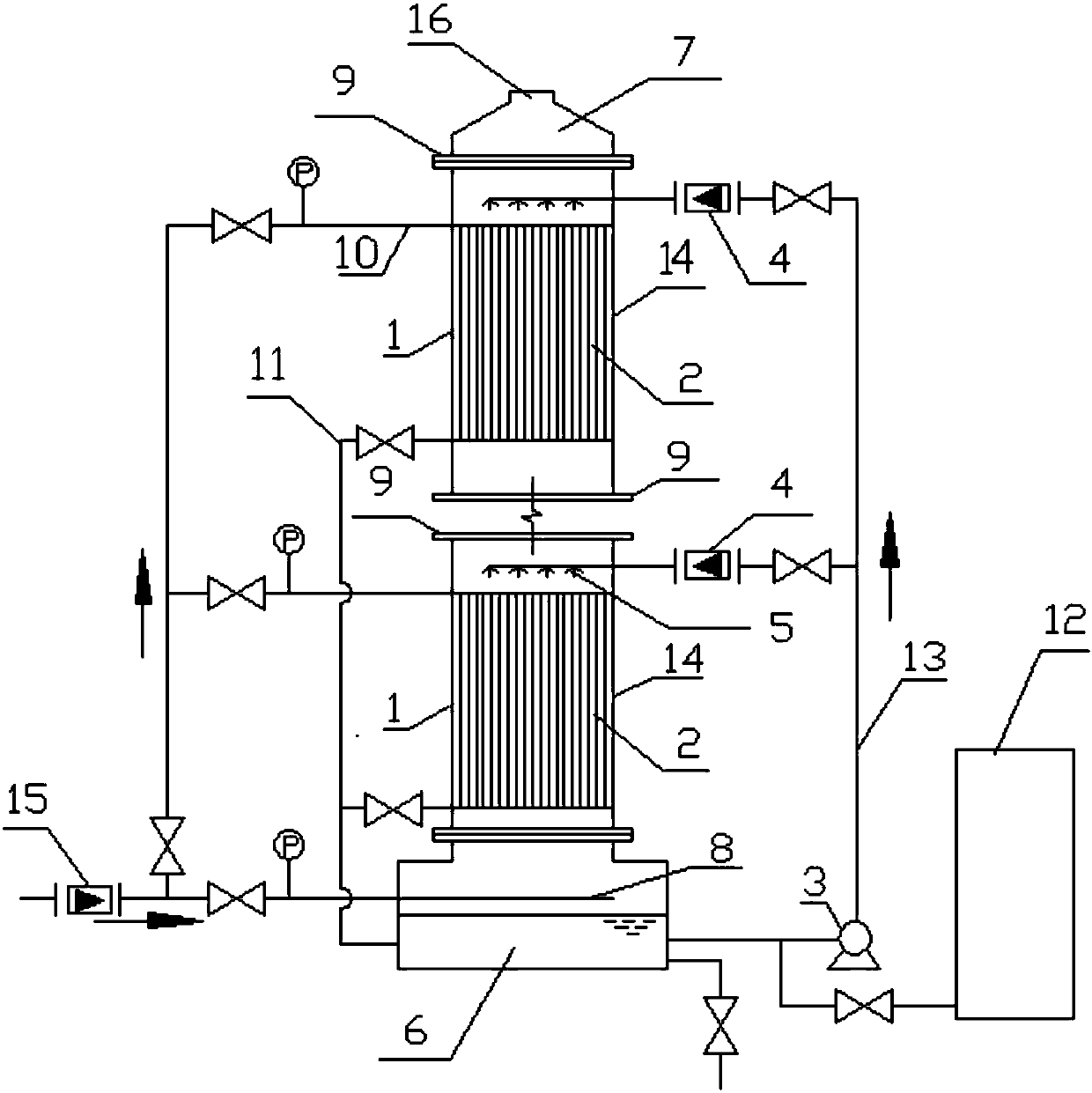

[0042] (3) Three bioreaction modules 14 are selected, and every two bioreaction modules are connected by a flange, and the bioreaction module is connected with the purified gas collection device 7 and the liquid storage base 6 by a flange;

[0043] (4) start the nutrient solution circulating pump 3; the nutrient solution spraying device sprays the nutrient solution;

[0044] (5) Divide the waste gas containing VOCs into two streams after passing through the waste gas flow meter 15, and one stream passes through three membrane aeration inlet pipes 10 respectively, and then enters the inside of the hollow fiber membrane; organic pollutant...

Embodiment 2

[0054] A method for purifying waste gas containing VOCs by a membrane aerated biofilm reactor, comprising the steps of:

[0055] Step (1)-step (7) is the same as embodiment 1 step (1)-step (7);

[0056] The nutrient solution spraying device is a nozzle-type distributor, and the small holes on the nozzle-type distributor are arranged in concentric circles, and the diameter of the small holes is 5-10mm;

[0057] The diameter of the cylindrical biological reaction tower body 1 is 1000mm, the height of the cylindrical biological reaction tower body 1 is 1000mm, and the height of the hollow fiber module module is 800mm. The filling density of the hollow fiber module is 50%. 3 biological reaction modules connected in series,

[0058] The exhaust gas flow rate containing xylene is 10‐20m 3 / s, the concentration is 800‐1000mg / m 3 .

[0059] The removal rate of xylene is 90%.

Embodiment 3

[0061] A method for purifying waste gas containing VOCs by a membrane aerated biofilm reactor, comprising the steps of:

[0062] Step (1)-step (7) is the same as embodiment 1 step (1)-step (7);

[0063] The nutrient solution spraying device is a nozzle-type distributor, and the small holes on the nozzle-type distributor are arranged in concentric circles, and the diameter of the small holes is 5-10mm;

[0064] The diameter of the cylindrical biological reaction tower body 1 is 1000mm, the height of the cylindrical biological reaction tower body 1 is 1200mm, and the height of the hollow fiber module module is 1000mm. The filling density of the hollow fiber module is 50%. 1 bioreaction module.

[0065] The flow rate of waste gas containing toluene is 25m‐30 3 / s, the concentration is 1200‐1500mg / m 3 .

[0066] The removal rate of toluene is 95%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com