a cr 3+ Doped aluminum-rich magnesium aluminum spinel fluorescent transparent ceramics and preparation method thereof

A magnesia-aluminum spinel and transparent ceramic technology, which is applied in the preparation of ceramic materials and the preparation of chromium-doped aluminum-rich magnesia-aluminum spinel fluorescent transparent ceramics, can solve the problem of affecting the luminous efficiency of white light LEDs, restricting white light LEDs, red light The luminous efficiency and stability of phosphors cannot be compared with those of yellow and green phosphors, which can solve the problem of the decline of fluorescence performance, the conversion of heat dissipation and light efficiency, and the technical convenience and easy regulation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] Mg 7.1 al 16.599 Cr 0.001 □ 0.3 o 32 Preparation of Fluorescent Transparent Ceramics

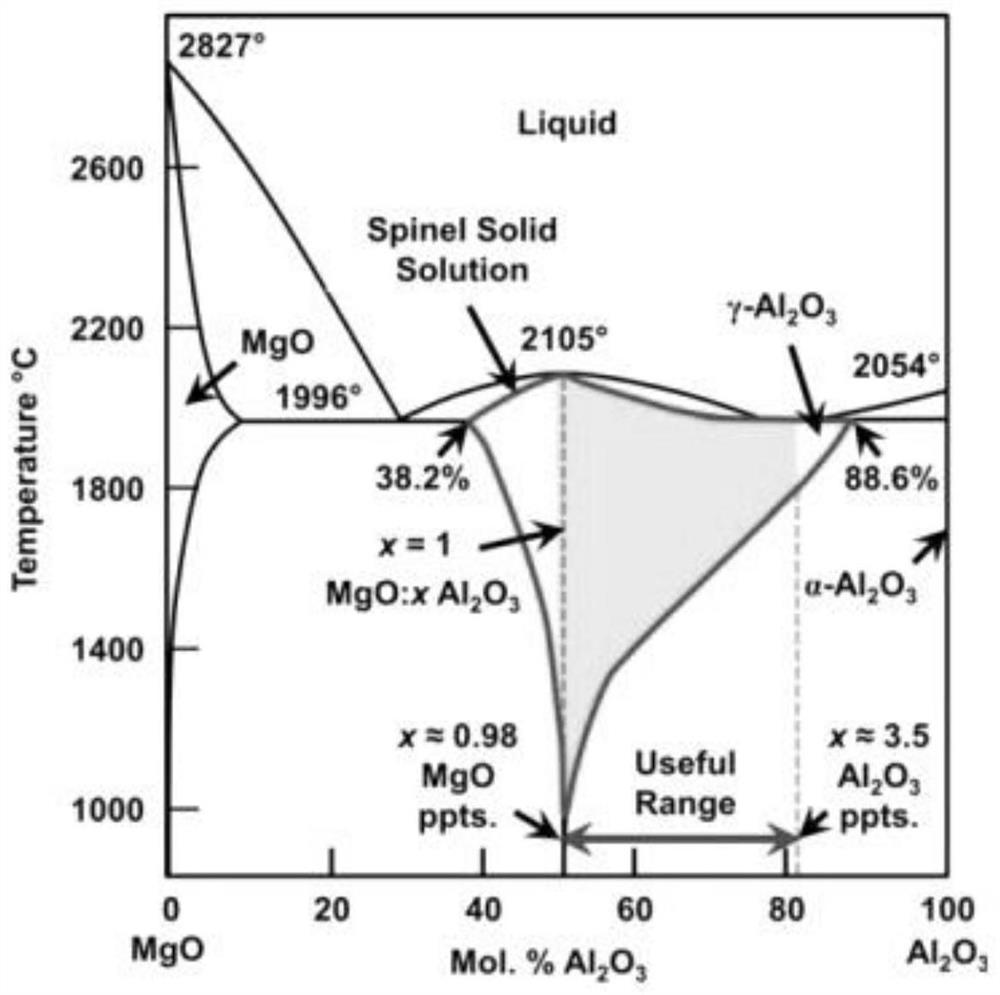

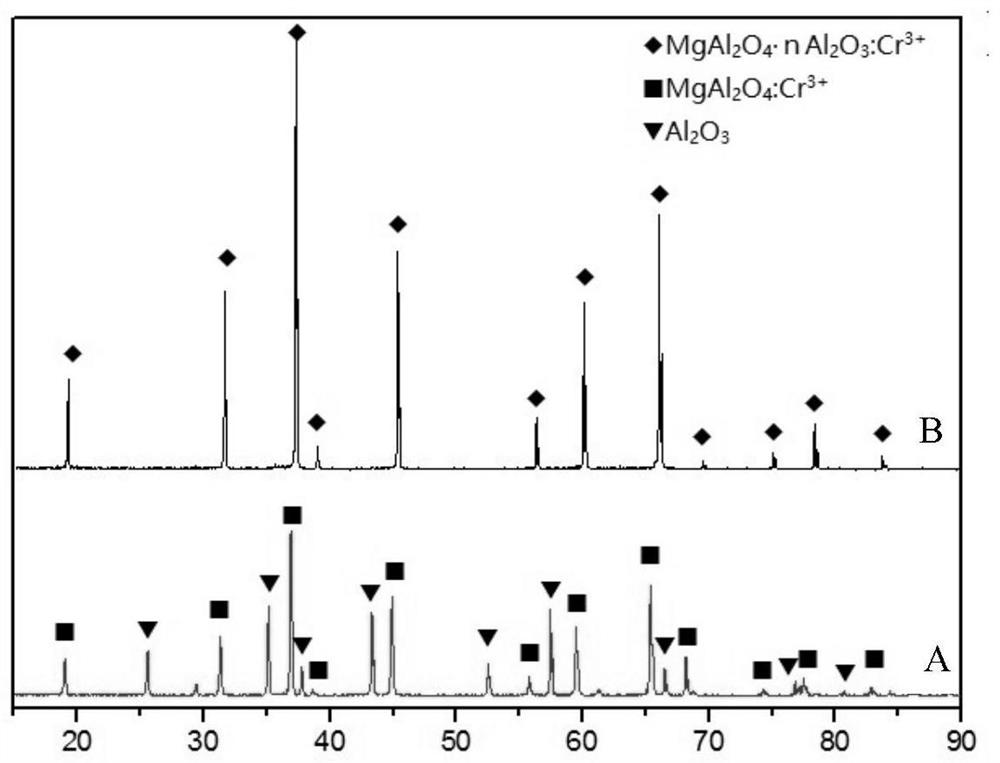

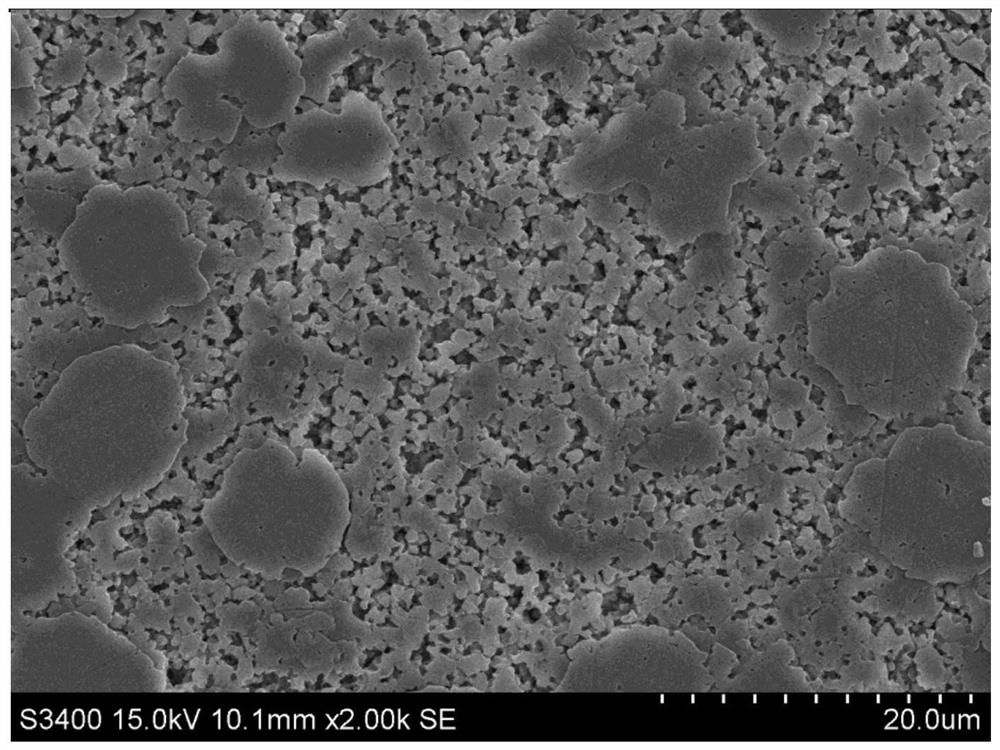

[0041] 1)MgAl 2 o 4 :Cr 3+ / Al 2 o 3 Preparation of multiphase ceramic green body: MgO, Al 2 o 3 、Cr 2 o 3 The powder is weighed according to the percentage of the amount of substance 1:0.9995:0.0005, and added to absolute ethanol, ball milled for 6 hours, and then the obtained slurry is fully dried to obtain a powder mixture, and a high-temperature solid-state reaction at 1300°C for 10 minutes is used to synthesize a single-phase stoichiometry MgAl 2 o 4 :Cr 3+ The ceramic powder; then the MgAl 2 o 4 :Cr 3+ and Al 2 o 3 The powder is weighed according to the percentage of substance amount 71:12, and added to absolute ethanol, ball milled for 6 hours, and the obtained slurry is fully dried to obtain a powder mixture, and a single-phase stoichiometric MgAl is synthesized by a high-temperature solid-state reaction 2 o 4 :Cr 3+ The ceramic powder is sieved, placed ...

Embodiment 2

[0045] Mg 6.5 Al 16.999 Cr 0.01 □ 0.5 o 32 Preparation of Fluorescent Transparent Ceramics

[0046] 1) Mg 8 Al 2 o 4 / Al 2 o 3 Preparation of multiphase ceramic green body: MgO, Al 2 o 3 、Cr 2 o 3 The powder is weighed according to the percentage of the amount of substance 1:0.995:0.005, and added to absolute ethanol, ball milled for 24 hours, and then the obtained slurry is fully dried to obtain a powder mixture, and a high-temperature solid-state reaction at 1300°C for 10 minutes is used to synthesize a single-phase stoichiometric MgAl 2 o 4 :Cr 3+ The ceramic powder; then the MgAl 2 o 4 :Cr 3+ and Al 2 o 3 The powder is weighed according to the percentage of substance amount 13:4, and added to absolute ethanol, ball milled for 24 hours, and the obtained slurry is fully dried to obtain a powder mixture, and a single-phase stoichiometric MgAl is synthesized by a high-temperature solid-state reaction 2 o 4 :Cr 3+ The ceramic powder is sieved, placed in a...

Embodiment 3

[0051] Mg 5.6 Al 17.584 Cr 0.016 □ 0.8 o 32 Preparation of Fluorescent Transparent Ceramics

[0052] 1)MgAl 2 o 4 :Cr 3+ / Al 2 o 3 Preparation of multiphase ceramic green body: MgO, Al 2 o 3 、Cr 2 o 3 The powder is weighed according to the percentage of substance amount 1:0.992:0.008, and added to absolute ethanol, ball milled for 24 hours, and then the obtained slurry is fully dried to obtain a powder mixture, and a high-temperature solid-state reaction at 1300°C for 10 minutes is used to synthesize a single-phase stoichiometric MgAl 2 o 4 :Cr 3+ The ceramic powder; then the MgAl 2 o 4 :Cr 3+ and Al 2 o 3 The powder is weighed according to the percentage of substance amount 7:4, and added to absolute ethanol, ball milled for 24 hours, and the obtained slurry is fully dried to obtain a powder mixture, and a single-phase stoichiometric MgAl is synthesized by a high-temperature solid-state reaction 2 o 4 :Cr 3+ The ceramic powder is sieved, placed in a ste...

PUM

| Property | Measurement | Unit |

|---|---|---|

| porosity | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com