A kind of saline-alkali soil salinity conditioner and preparation method thereof

A saline-alkali soil and conditioner technology, applied in soil conditioning materials, chemical instruments and methods, and other chemical processes, can solve the problems of low germination rate of crops, large amount of gypsum, and difficult washing, etc., to prevent soil crusting , increase the penetration capacity, reduce the effect of salinization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

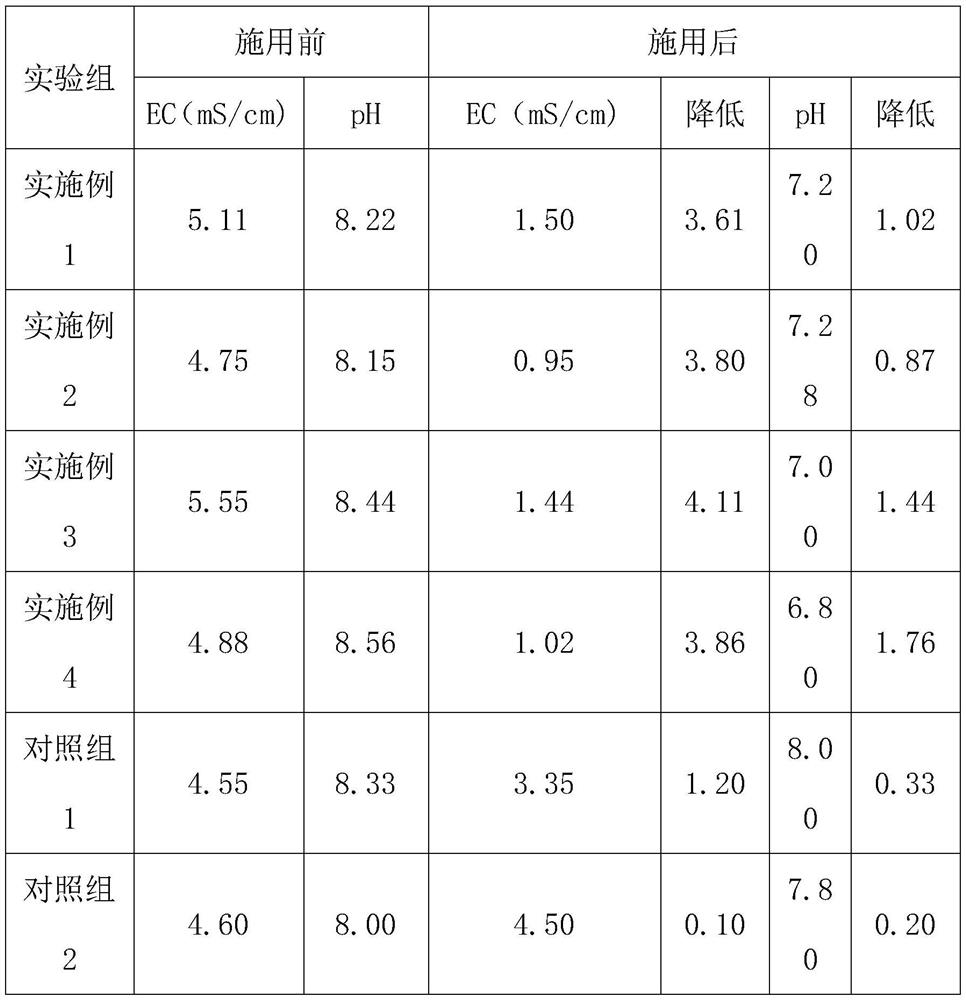

Examples

Embodiment 1

[0022] A saline-alkali soil salinity conditioner of the present invention comprises the following components in parts by weight: 50 parts of calcium salt, 5 parts of sorbitol solution, 22 parts of urea phosphate, and 25 parts of water.

[0023] The preparation method of the saline-alkali soil salinity conditioner of the above-mentioned present embodiment comprises the following steps:

[0024] Rinse the reaction kettle with purified water, pump some purified water into the reaction kettle, raise the temperature to 70°C, put 50 parts of calcium nitrate into the reaction kettle, heat properly to maintain the feeding temperature at about 50°C, so that the solid can be fully Dissolve; heat up to 65-70°C after feeding the calcium salt, mix and stir, and the solid is fully dissolved; pump 5 parts of sorbitol liquid into the reaction kettle, continue to keep warm to 65-70°C, keep warm for 2 hours, add hot After fully dissolving 22 parts of urea phosphate in water, continue to keep wa...

Embodiment 2

[0026] Rinse the reaction kettle with purified water, pump some purified water into the reaction kettle, raise the temperature to 70°C, put 50 parts of calcium nitrate into the reaction kettle, heat properly to maintain the feeding temperature at about 50°C, so that the solid can be fully Dissolve; heat up to 65-70°C after feeding the calcium salt, mix and stir, and the solid is fully dissolved; pump 5 parts of sorbitol liquid into the reaction kettle, continue to keep warm to 65-70°C, keep warm for 2 hours, add hot After fully dissolving 20 parts of urea phosphate in water, continue to keep warm at 70-75°C, mix and stir for 7 hours, turn off the heating, continue to stir, and naturally cool down to room temperature to obtain a clear liquid, which is the saline-alkali soil salt of this embodiment. Conditioning agent.

Embodiment 3

[0028] Rinse the reaction kettle with purified water, pump some purified water into the reaction kettle, raise the temperature to 70°C, put 50 parts of calcium nitrate into the reaction kettle, heat properly to maintain the feeding temperature at about 50°C, so that the solid can be fully Dissolve; heat up to 65-70°C after feeding the calcium salt, mix and stir, and the solid is fully dissolved; pump 5 parts of sorbitol liquid into the reaction kettle, continue to keep warm to 65-70°C, keep warm for 2 hours, add hot After fully dissolving 23 parts of urea phosphate in water, continue to keep warm at 70-75°C, mix and stir for 7 hours, turn off the heating, continue to stir, and naturally cool down to room temperature to obtain a clear liquid, which is the saline-alkali soil salt of this embodiment. Conditioning agent.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com