Nitrogen-cobalt double-doped porous carbon composite bifunctional oxygen catalyst and its preparation method and application

An oxygen catalyst and composite technology, which is applied in structural parts, electrolysis components, electrolysis processes, etc., to achieve the effects of easy operation, excellent activity and simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] (a) Preparation of melamine / Co-SA composite

[0033]Disperse a certain amount of SA in 200mL deionized water, heat and stir at 80°C for 8h to dissolve completely, and prepare a SA solution with a concentration of 5mg / mL; add cobalt chloride hexahydrate into deionized water, and prepare a cobalt ion concentration of 0.02mol / L 150mL of the solution was slowly added dropwise to the SA solution during stirring, centrifuged at 4000rpm for 10min after stirring for 4h, the collected precipitate was redispersed in 200mL of deionized water, then 5g of melamine was added, heated to 80°C and stirred for 1h, the The above mixed solution was transferred into a reaction kettle, subjected to hydrothermal reaction at 120-150°C for 8 hours, the reaction solution was centrifuged and washed three times with deionized water and ethanol in sequence, and dried to obtain a melamine / Co-SA composite;

[0034] (b) Preparation of Co / NPC bifunctional oxygen catalyst

[0035] Grind the melamine / Co...

Embodiment 2

[0037] (a) Preparation of melamine / Co-SA composite

[0038] Disperse a certain amount of SA in 200mL deionized water, heat and stir at 80°C for 8h to dissolve completely, and prepare a SA solution with a concentration of 10mg / mL; add cobalt chloride hexahydrate into deionized water, and prepare a cobalt ion concentration of 0.02mol / L 150mL of the solution was slowly added dropwise to the SA solution during stirring, centrifuged at 4000rpm for 10min after stirring for 4h, the collected precipitate was redispersed in 200mL of deionized water, then 5g of melamine was added, heated to 80°C and stirred for 1h, the The above mixed solution was transferred into a reaction kettle, subjected to hydrothermal reaction at 120-150°C for 8 hours, the reaction solution was centrifuged and washed three times with deionized water and ethanol in sequence, and dried to obtain a melamine / Co-SA composite;

[0039] (b) Preparation of Co / NPC bifunctional oxygen catalyst

[0040] Prepare according t...

Embodiment 3

[0043] (a) Preparation of melamine / Co-SA composite

[0044] Prepare according to the method and conditions of step (a) in Example 2.

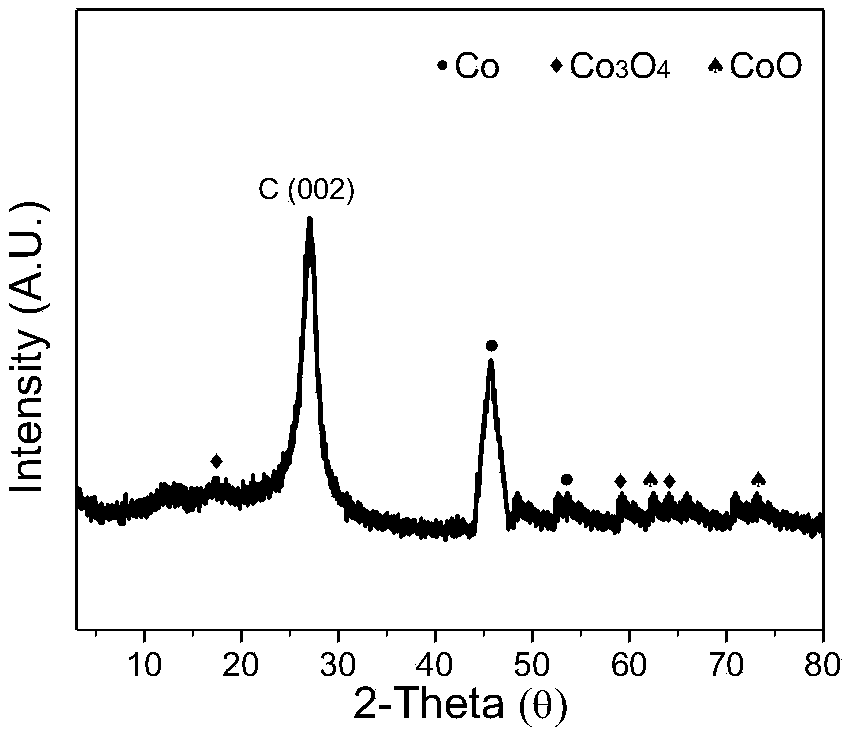

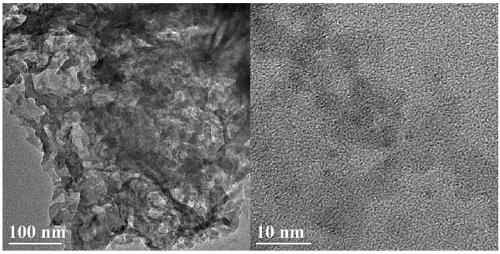

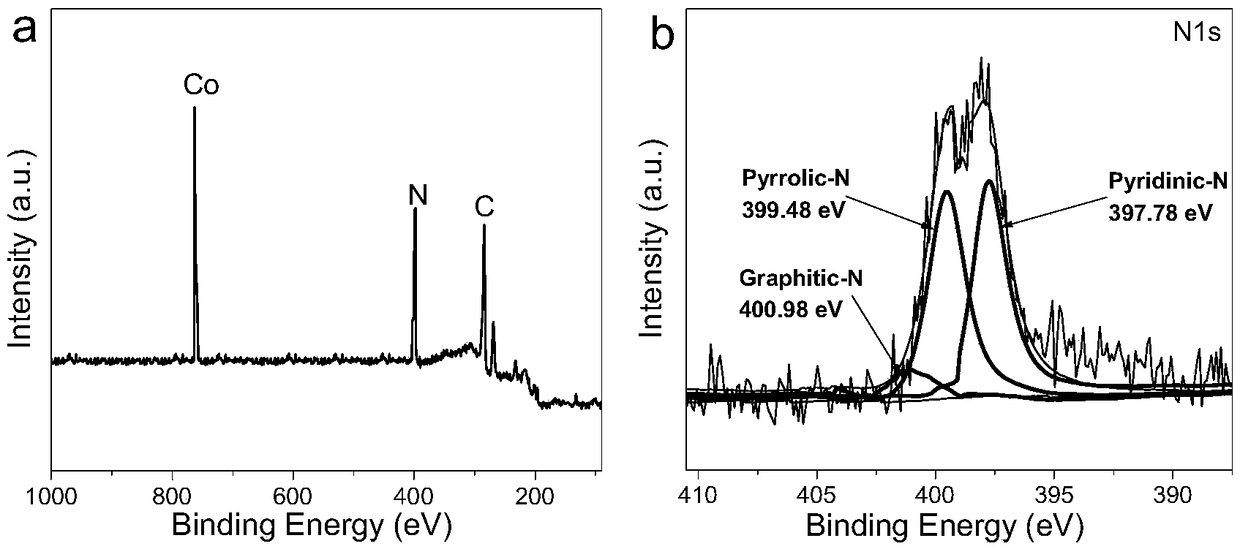

[0045] (b) Preparation of Co / NPC bifunctional oxygen catalyst

[0046] Grind the melamine / Co-SA composite obtained in step (a) into powder, put a certain amount in a porcelain boat in a tube furnace, heat at a rate of 5°C / min under a nitrogen atmosphere, and first raise to Heating at 200°C for 1 hour, then heating to 700°C for 4 hours to obtain the Co / NPC bifunctional oxygen catalyst with an average pore diameter of 2.2-6.8nm and a specific surface area of 168.84m 2 / g.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com