Environmentally-friendly color-changing packaging leather and preparation method thereof

An environmentally friendly, temperature-sensitive discoloration technology, applied in the field of synthetic leather, can solve the problems of reducing pollution, undercoating, environmental pollution, etc., and achieve the effects of uniform color development, quality improvement, and uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

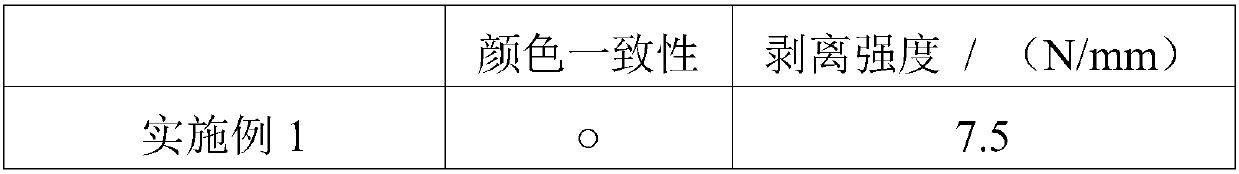

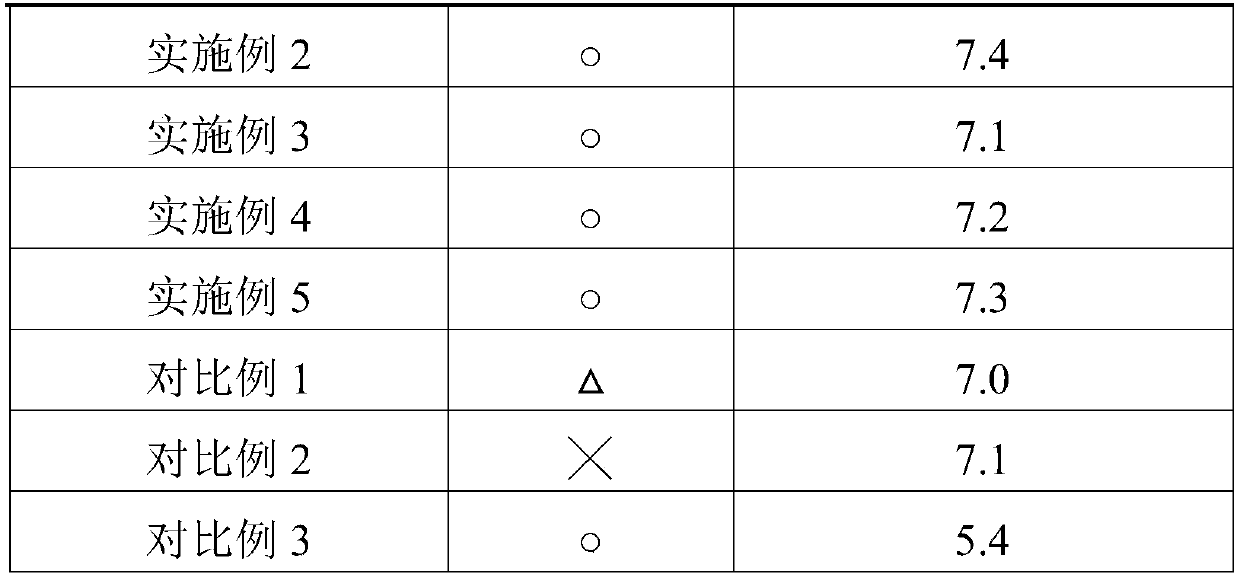

Examples

Embodiment 1

[0024] A preparation method of environment-friendly color-changing packaging leather:

[0025] (1) Take the water-based polyurethane solution and distilled water according to the mass ratio of 1:2, apply it on the release paper, and bake it at 120°C for 2 minutes to obtain the surface layer-release paper;

[0026] (2) Dispersing the vanadium dioxide nanoparticles into an aqueous solution of polyethylene glycol, and then evaporating the water under constant stirring conditions to obtain vanadium dioxide nanoparticles coated with polyethylene glycol;

[0027] (3) After mixing 0.5 parts of oleic acid acyl and 12 parts of the above-mentioned modified vanadium dioxide nanoparticles, add them to 45 parts of water-based polyurethane, add 38 parts of water to stir and mix, and then add 0.7 parts of organic silicon defoamer and 7 parts of n-decyltriethoxysilane to obtain the thermochromic layer slurry, coat the thermochromic layer slurry on the surface layer-release paper, and bake at ...

Embodiment 2

[0031] A preparation method of environment-friendly color-changing packaging leather:

[0032] (1) Take the water-based polyurethane solution and distilled water according to the mass ratio of 1:2.2, apply it on the release paper, and bake it at 115°C for 2 minutes to obtain the surface layer-release paper;

[0033] (2) Dispersing the vanadium dioxide nanoparticles into an aqueous solution of polyethylene glycol, and then evaporating the water under constant stirring conditions to obtain vanadium dioxide nanoparticles coated with polyethylene glycol;

[0034] (3) After mixing 0.4 parts of oleic acid acyl and 10 parts of the above-mentioned modified vanadium dioxide nanoparticles, add them to 38 parts of water-based polyurethane, add 34 parts of water to stir and mix, and then add 0.4 parts of organic silicon defoamer and 4 parts of n-decyltrimethoxysilane to obtain the thermochromic layer slurry, apply the thermochromic layer slurry on the surface layer-release paper, and bake...

Embodiment 3

[0038] A preparation method of environment-friendly color-changing packaging leather:

[0039](1) Take the water-based polyurethane solution and distilled water according to the mass ratio of 1:2.5, apply it on the release paper, and bake it at 125°C for 2 minutes to obtain the surface layer-release paper;

[0040] (2) Dispersing the vanadium dioxide nanoparticles into an aqueous solution of polyethylene glycol, and then evaporating the water under constant stirring conditions to obtain vanadium dioxide nanoparticles coated with polyethylene glycol;

[0041] (3) Mix 1 part of glyceryl tristearate with 17 parts of the above-mentioned modified vanadium dioxide nanoparticles and add it to 50 parts of water-based polyurethane, add 42 parts of water to stir and mix, and then add 1.2 parts of silicone disinfectant foaming agent and 10 parts of n-decyltriethoxysilane to obtain the thermochromic layer slurry, and coat the thermochromic layer slurry on the surface layer-release paper a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com