Metal oxide-sulfide composite negative electrode material and preparation method thereof

A negative electrode material and oxide technology, which is applied in the field of preparation of new metal oxides/sulfides, can solve problems affecting the electrochemical performance and volume expansion of lithium-ion batteries, and achieve green and environmentally friendly reaction conditions, reduce production costs, and wide application foreground effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

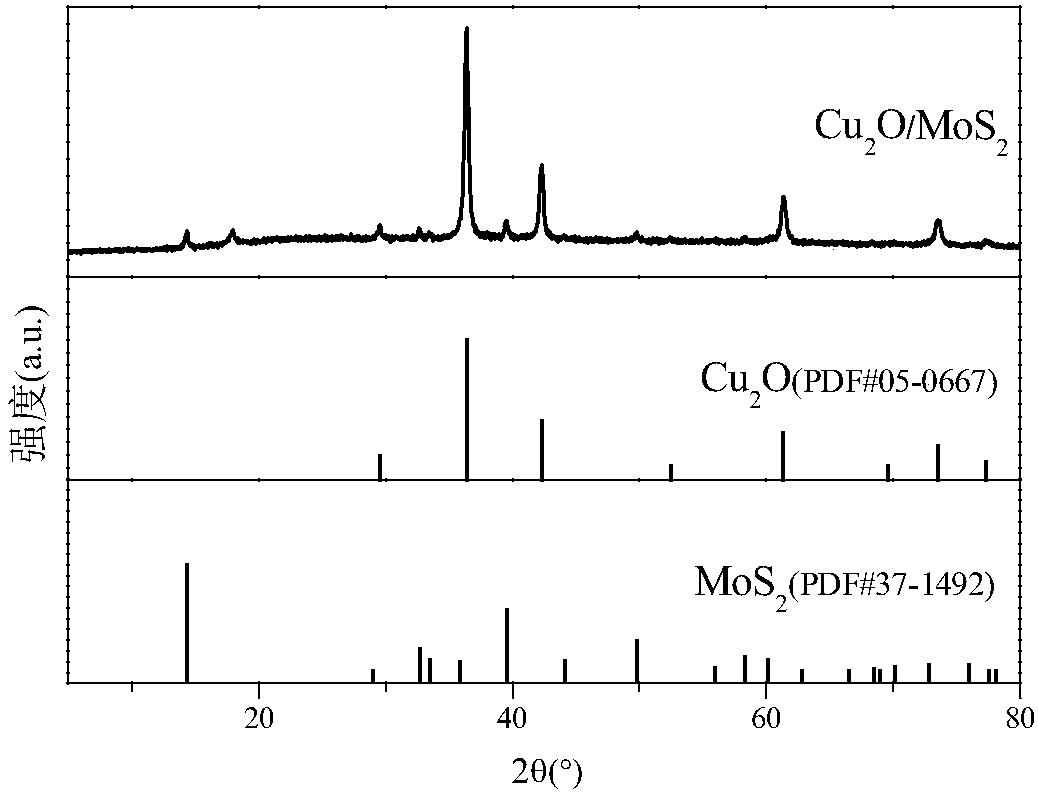

[0031] Step 1, add 350 μl of 0.1M CuSO 4 .5H 2 O aqueous solution and 350 μL of 1.0M NaOH aqueous solution were mixed in a water bath at a certain temperature, and stirred for 3-5 minutes, then AA (ascorbic acid) aqueous solution was added thereto, and stirred for 10 minutes in a water bath at a certain temperature to make crystals grow. Afterwards, several times of centrifugation and washing with deionized water and absolute ethanol can obtain 2 O nanoparticles, spare.

[0032] Step 2, the MoS 2 Add the powder (finished product) into NMP and shake continuously to make MoS 2 Uniform powder

[0033] Dispersed in NMP, the concentration of the dispersion is 1mg L -1 , sonicated for 1h on stacked MoS 2 Perform stripping. Centrifuge the stripped dispersion at 3000rpm, absorb the supernatant (about 1 / 2 of the total dispersion), and then centrifuge the obtained supernatant at 14000rpm to remove NMP to obtain MoS 2 Flakes.

[0034] Step 3, the Cu obtained in step 1 and step 2...

Embodiment 2

[0042] Step 1, the CuSO 4 When dissolved in deionized water and mixed with 1.0M NaOH solution, the amount of NaOH solution is 425 μL, and other conditions are the same as step (1) in Example 1.

[0043] Step 2, the MoS 2 Add the powder (finished product) into NMP and shake continuously to make MoS 2 The powder is evenly dispersed in NMP, the concentration of the dispersion is 1mg L -1 , when processing the dispersion, the ultrasonic time was 2h, and other conditions were the same as step 2 in Example 1.

[0044] Step 3 is the same as Step 3 in Example 1.

[0045] The electrochemical test steps are the same as in Example 1.

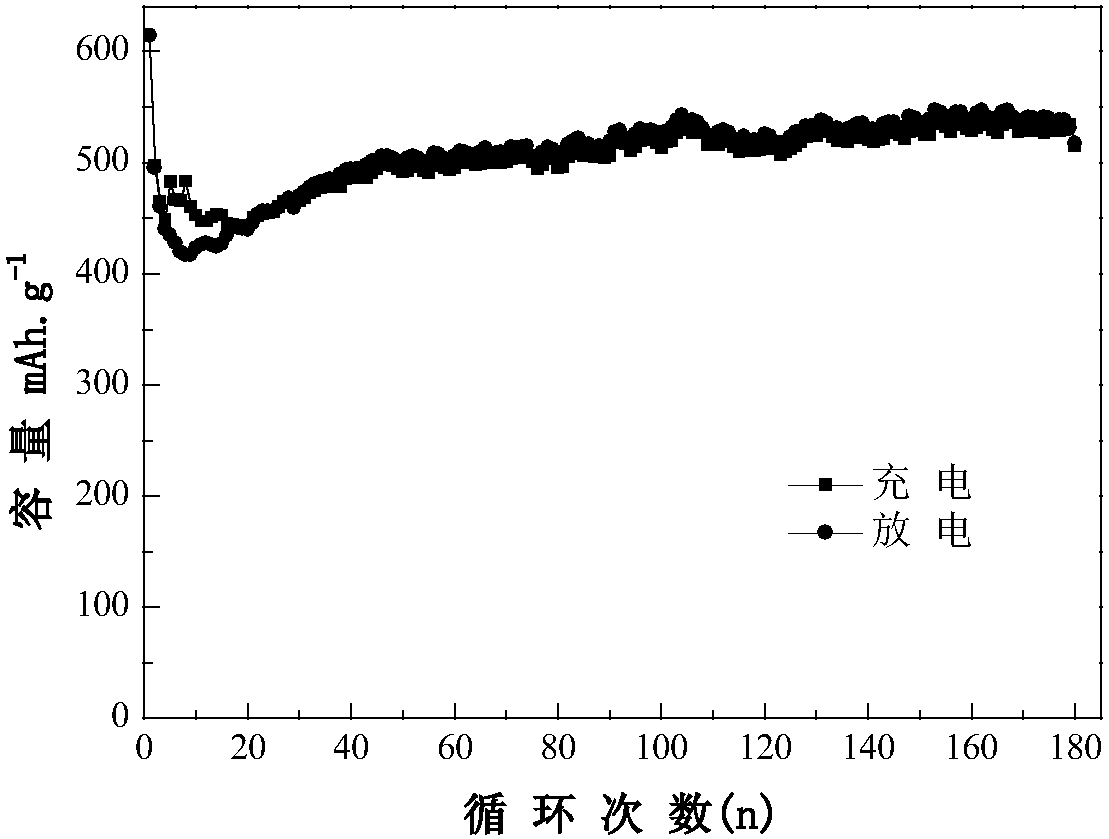

[0046] The first cycle discharge specific capacity of the material obtained in this example is 687.4mAh g -1 , the specific capacity of the first cycle charging is 476.3mAh g -1 , after 60 charge-discharge cycles, the capacity retention rate is about 94.5%.

Embodiment 3

[0048] Step 1, the CuSO 4 When dissolved in deionized water and mixed with 1.0M NaOH solution, the volume of NaOH solution is 550 μL, and other conditions are the same as step 1 in Example 1.

[0049] Step 2, the conditions are the same as Step 2 in Example 1.

[0050] Step 3, the conditions are the same as Step 3 in Example 1.

[0051] The electrochemical test steps are the same as in Example 1.

[0052] The first cycle discharge specific capacity of the material obtained in this example is 534.4mAh g -1 , the specific capacity of the first cycle charge is 457.6mAh g -1 , after 100 charge-discharge cycles, the capacity retention rate is about 89.5%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com