A kind of preparation method of nickel-cobalt-manganese ternary precursor with low sulfur and high tap density

A technology of nickel-cobalt-manganese ternary and tap density, which is applied in the direction of electrical components, structural parts, battery electrodes, etc., can solve the problems of not meeting high tap density and low sulfur content at the same time, and achieve high density and low concentration of lye Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

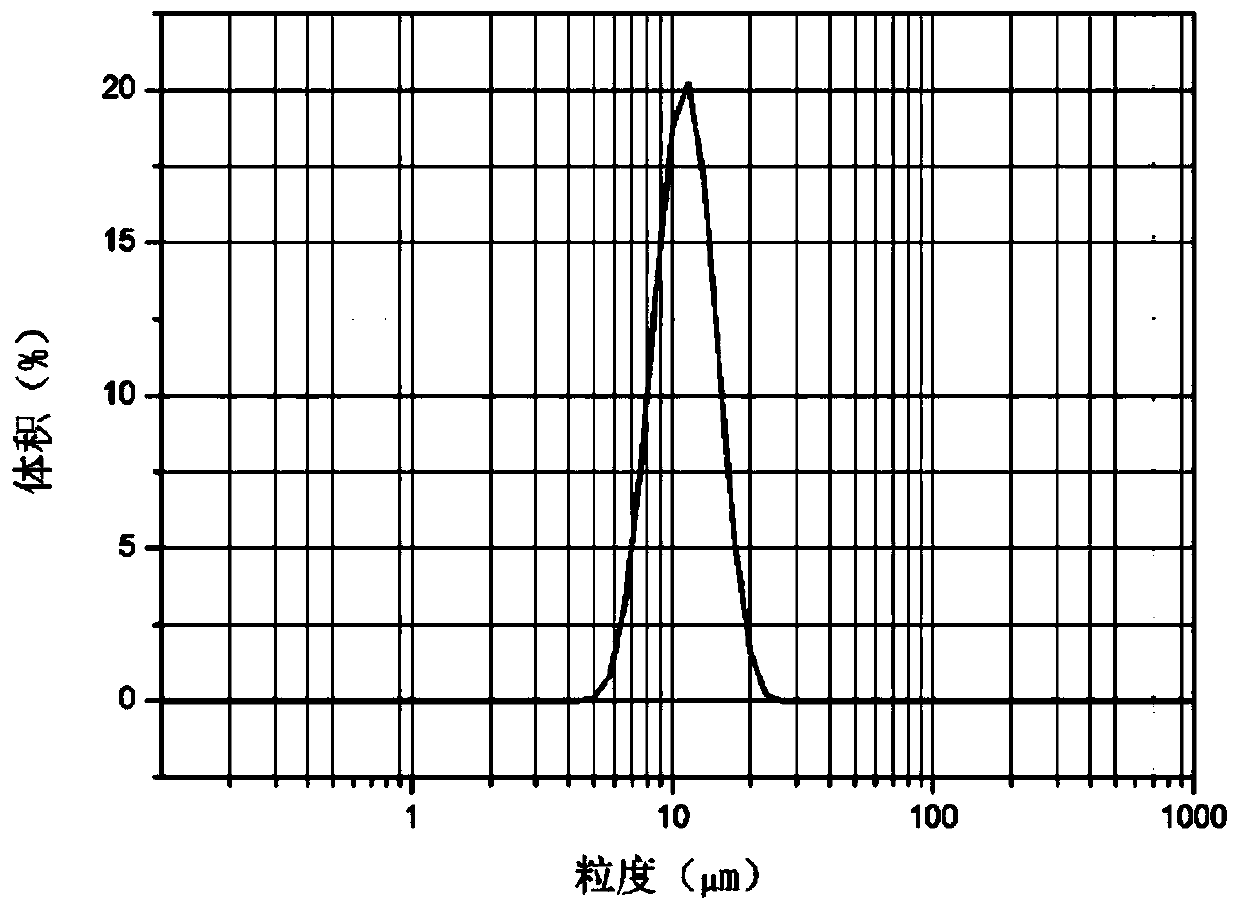

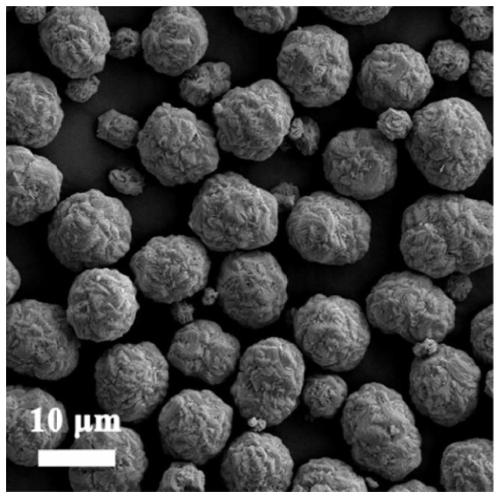

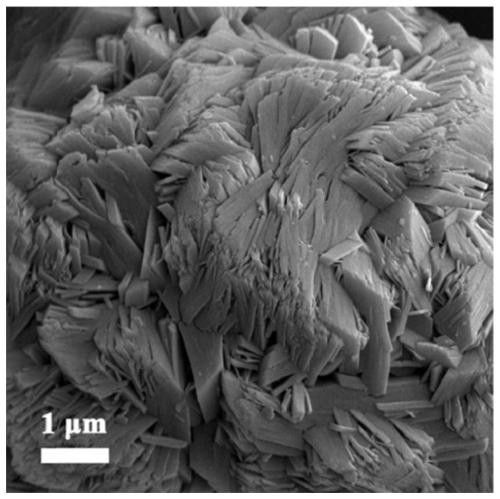

[0027] Low sulfur high tap density Ni 1 / 3 co 1 / 3 mn 1 / 3 (OH) 2 The preparation of ternary precursor, D50 is 10.4μm, TD is 2.30g / cc, S content is 1071ppm, the preparation process is as follows:

[0028] (1) According to Ni 1 / 3 co 1 / 3 mn 1 / 3 (OH) 2 The molar ratio of nickel, cobalt and manganese in the medium weighs the weight of nickel sulfate, cobalt sulfate and manganese sulfate, and adds pure water to make a mixed solution. The total concentration of metal content in the mixed solution is 1.5mol / L; the concentration of the lye is 5mol / L, Configure the concentration of ammonia water to be 15%.

[0029] (2) Use a 200L titanium reactor with controllable temperature and speed, add 40-50L pure water as the bottom liquid before starting the machine, start stirring to 595-605rpm, heat up to 53-57°C, add ammonia and lye, and adjust the bottom liquid When the pH value reaches 12.25~12.35, the ammonia value is 4~5g / L, and after 0.1~0.2 hours of passing through the protective g...

Embodiment 2

[0034] Low sulfur high tap density Ni 0.5 co 0.2 mn 0.3 (OH) 2 The preparation of the ternary precursor, the D50 is 12.5 μm, the TD is 2.32g / cc, and the S content is 1100ppm. The preparation process is as follows:

[0035] (1) According to Ni 0.5 co 0.2 mn 0.3 (OH) 2 The molar ratio of nickel, cobalt and manganese in the middle weighs the weight of nickel sulfate, cobalt sulfate and manganese sulfate, and adds pure water to form a mixed solution. The total concentration of metal content in the mixed solution is 2mol / L; The concentration of ammonia water is 20%.

[0036] (2) Use a 5000L titanium reactor with controllable temperature and speed, add 1000-1200L pure water as the bottom liquid before starting the machine, start stirring to 398-405rpm, heat up to 50°C, add ammonia and lye, and adjust the pH value of the bottom liquid To 11.55~11.65, the ammonia value is 6~7g / L, after 0.5h of the protective gas, the peristaltic pump of the metal material liquid, lye, and ammo...

Embodiment 3

[0041] Low sulfur high tap density Ni 0.8 co 0.1 mn 0.1 (OH) 2 The preparation of ternary precursor, D50 is 11.5μm, TD is 2.31g / cc, S content is 1007ppm, the preparation process is as follows:

[0042] (1) According to Ni 0.8 co 0.1 mn 0.1 (OH) 2 The molar ratio of nickel, cobalt and manganese in the middle Weigh the weight of nickel sulfate, cobalt sulfate and manganese sulfate, add pure water to make a mixed solution, the total concentration of metal content in the mixed solution is 2.5mol / L; the concentration of the lye is 6.5mol / L , configure the concentration of ammonia water to be 25%.

[0043] (2) Use a 50L titanium reactor with controllable temperature and speed, add 10-13L pure water as the bottom liquid before starting the machine, start stirring to 798-805rpm, heat up to 45°C, add ammonia and lye, and adjust the pH value of the bottom liquid To 11.95~12.05, the ammonia value is 5~6g / L, after 1 hour of protective gas, the peristaltic pump of metal material li...

PUM

| Property | Measurement | Unit |

|---|---|---|

| solid content | aaaaa | aaaaa |

| solid content | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com